Asymmetric multi-workshop integrated dispatching method with consideration of same-kind-of-equipment process

A technology of equipment process and scheduling method, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problem of less research results, improve the parallelism and balance of workshops, reduce the number of migrations, and shorten the actual completion of processing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

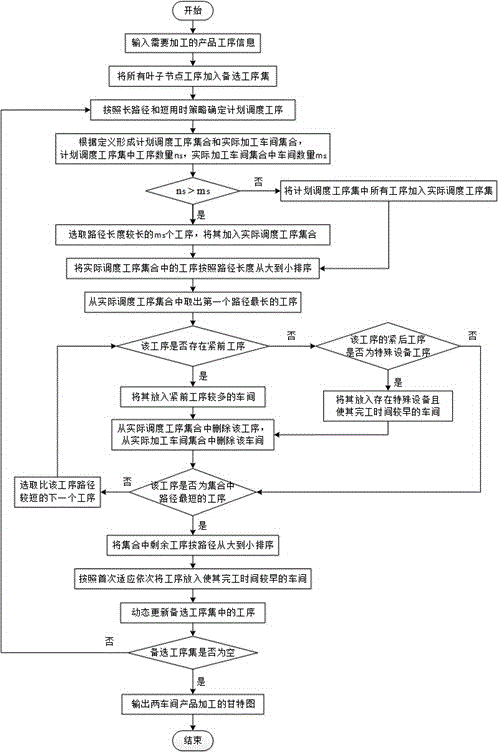

[0041]An asymmetrical multi-workshop comprehensive scheduling method considering the same equipment process is characterized in that: the method mainly includes the following steps: first, all leaf node processes are added to the candidate process set; The method determines the planning scheduling process from the candidate process set, and forms the planning scheduling process set from the same equipment process of the planning scheduling process, and then determines the actual scheduling process set through the long-path priority method of the same equipment process, and finally uses the multi-workshop process group scheduling balance method Allocate the processes in the actual scheduling process concentration to the appropriate processing workshops to improve the parallelism and balance of the workshops.

Embodiment 2

[0043] The above-mentioned asymmetric multi-workshop comprehensive scheduling method considering the same equipment process, the specific implementation steps of the scheduling method are as follows:

[0044] Step 1: Enter the process information of the product process tree, including process name, processing equipment and processing time;

[0045] Step 2: Add all leaf node processes to the set of candidate processes;

[0046] Step 3: Determine the planning and scheduling process according to the long path and short time, compare the path lengths of each process in the candidate process set, and select the process on the longest path; if the longest path process is not unique, select processing on the basis of the long path The process with the shortest duration is determined as the planning and scheduling process.

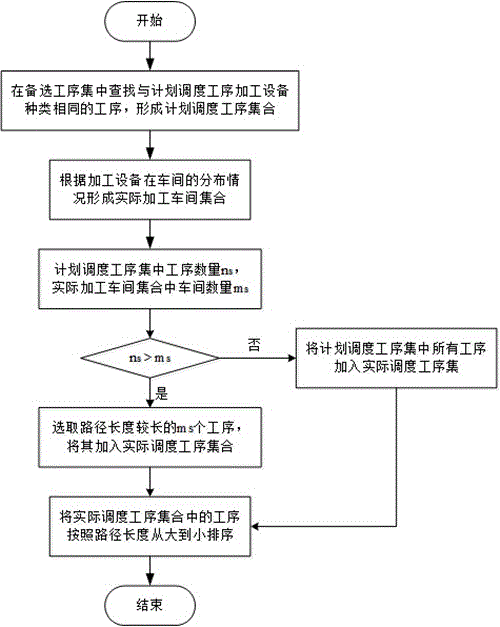

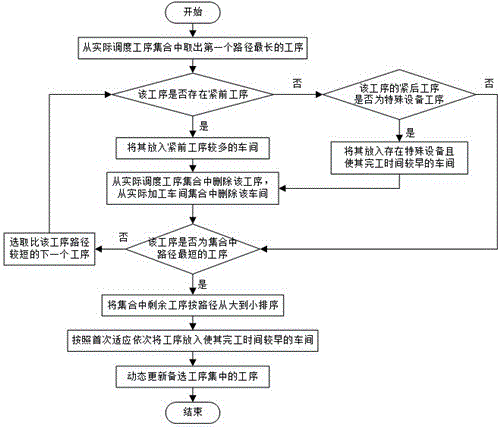

[0047] Step 4: Determine the type of processing equipment in the planned scheduling process, and find out whether there are other processes in the candidate proc...

Embodiment 3

[0058] In the asymmetric multi-workshop comprehensive scheduling method considering the same equipment process, in the above, all the leaf node processes are added to the candidate process set, and the planning and scheduling process is determined according to the method of preferentially selecting long path processes and short time-consuming processes, that is, from The process with the largest sum of processing time of each process on the path from the root node process to the node process is the long path process, and the process with the shortest processing time is the short time-consuming process.

[0059] In the asymmetric multi-workshop comprehensive scheduling method considering the same equipment process, the plan scheduling process set is formed by the same equipment process in the plan scheduling process, that is, to judge the processing equipment type of the plan scheduling process, and to find whether the candidate process set is There is the same process as the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com