Fault Diagnosis Method Based on Testability Model of Electronic Equipment

A technology for fault diagnosis of electronic equipment, applied in the field of measurement and control, can solve the problems of heavy workload, high cost, poor versatility and scalability, etc., achieve good versatility and scalability, reduce diagnostic steps, and improve diagnostic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

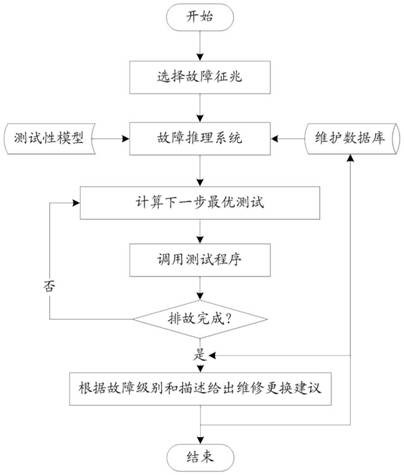

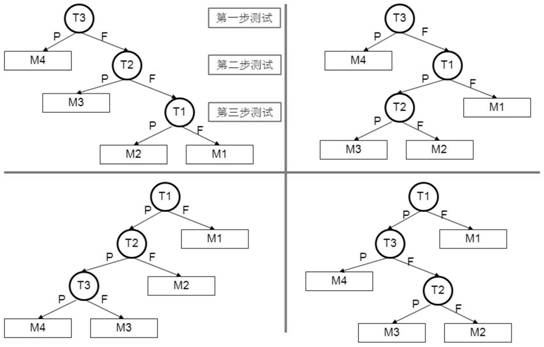

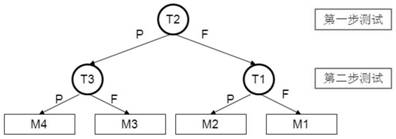

[0034] The fault diagnosis method proposed in the present invention is based on the testability model of electronic equipment, and establishes the corresponding relationship between equipment failure modes, signals and tests. The computer analyzes the test logic contained in the testability model according to the corresponding relationship. , automatically reasoning and performing corresponding tests on the diagnosis node. According to the current test results, before the next step of test diagnosis, the test process is optimized to realize the dynamic fault diagnosis logic. This method fundamentally overcomes the difficulty and high cost of manual troubleshooting. , Binary tree troubleshooting flexibility, poor versatility and scalability, etc., can realize electronic equipment automation and intelligent on-site fault diagnosis.

[0035] Specifically, firstly, according to the actual situation of the shipboard electronic equipment, a corresponding testable model is established...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com