Online quantitative recognition analysis method for loose fault of bearing support of rotor system

A bearing support and quantitative identification technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of few influencing factors and short paths, and achieve the reduction of influencing factors, accurate testing, and simple analysis and processing methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0065] Such as figure 1 As shown, an online quantitative identification and analysis method for a loosening fault of a bearing support of a rotor system of the present invention includes the following steps:

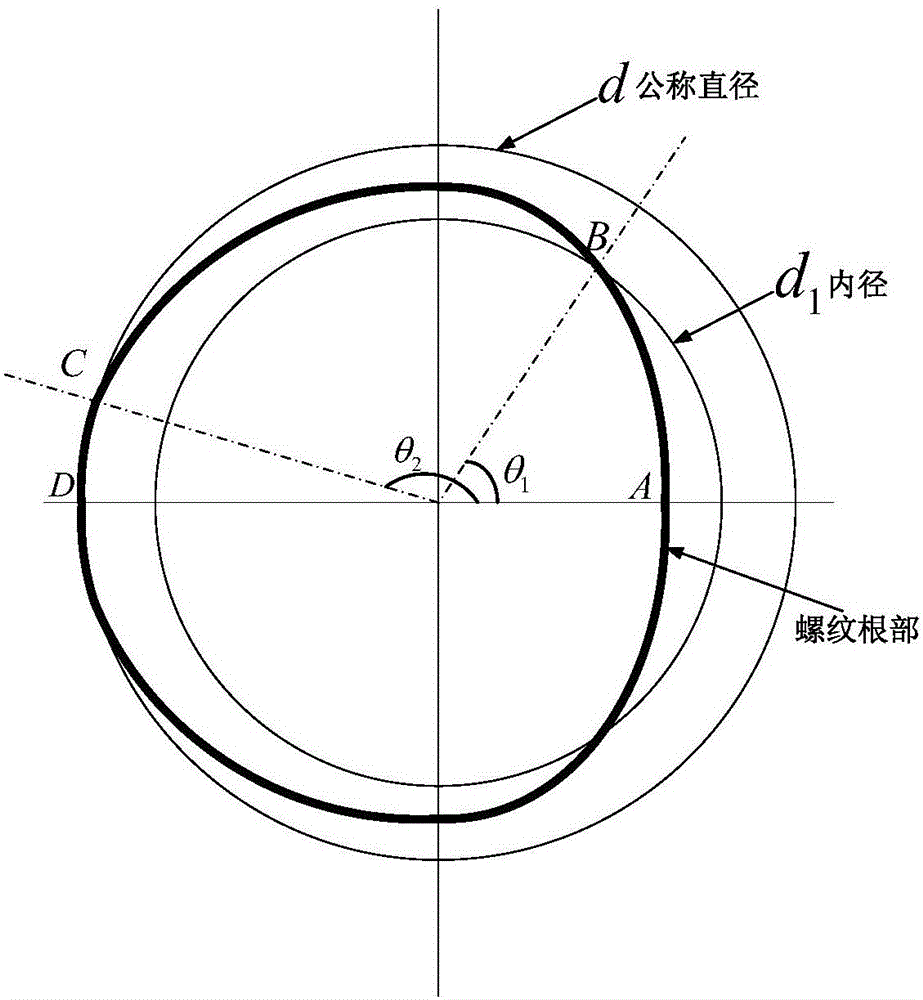

[0066] 1) Use finite element analysis software to establish a bolt model with spiral threads and a basic model of the rotor system with spiral internal threaded holes, replace the bearing support with a mass block, and connect the bearing support with the basic model of the rotor system with bolts ;

[0067] 2) Perform loosening analysis on the bolt connection finite element model established in 1) to obtain the change law between bolt looseness and bolt tension, and further obtain the pressure distribution law of the joint surface of the bolt connection under different bolt tensions , That is, the law of the load distribution between the joint surfaces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com