Pressure control device for high-pressure micro-flow experimental system

An experimental system and control device technology, applied in the direction of fluid pressure control, electric fluid pressure control, non-electric variable control, etc., can solve the problems of pressure regulation fluctuation, low control accuracy, narrow pressure control range, etc. The effect of constant pressure, stable pressure regulation and no fluctuation, and high pressure control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

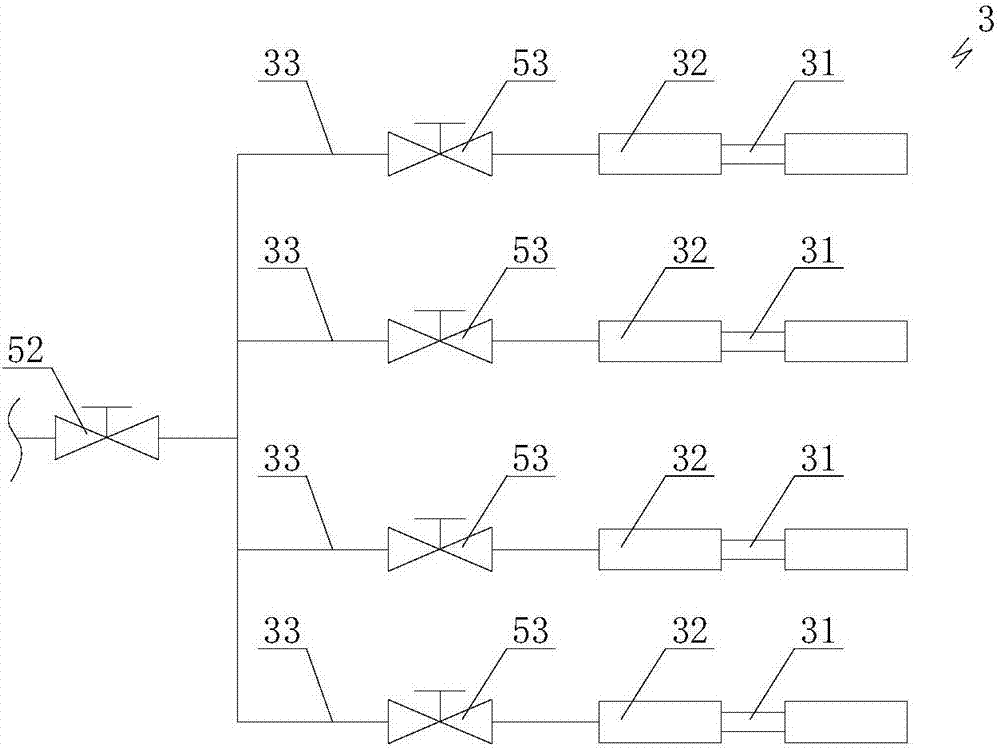

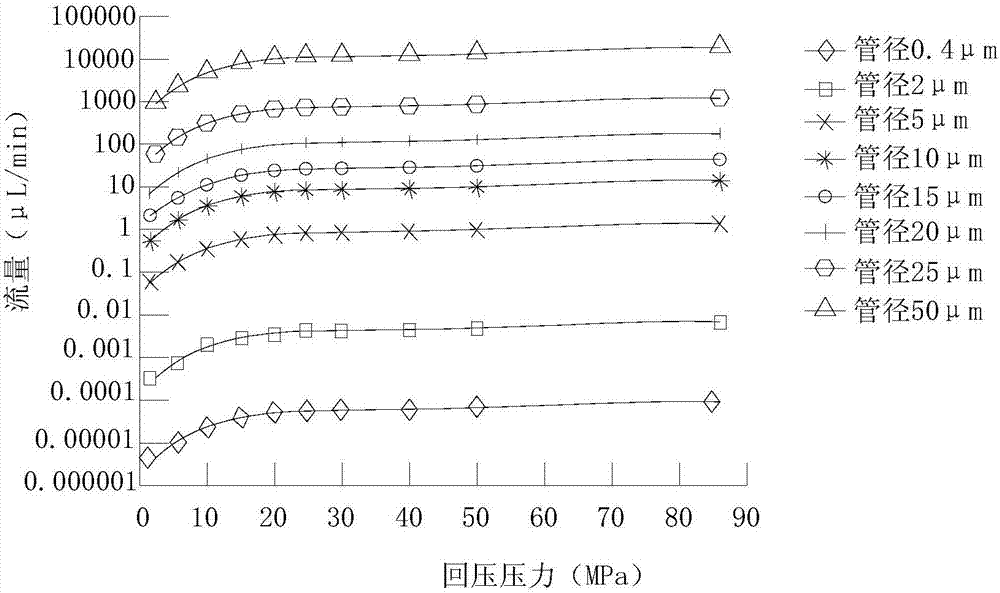

[0033] Such as Figure 1a As shown, the present invention provides a pressure control device 100 for a high-pressure micro-flow experimental system. The pressure of the high-pressure micro-flow experimental system is from normal pressure (1 atmosphere, i.e. 0.1 MPa) to 80 MPa, and the micro-flow rate is 0.0001 nL / min ~100000nL / min. The pressure control device 100 of the high-pressure micro-flow experimental system is connected to the outlet of the high-pressure micro-flow experimental system 9. The pressure control device 100 of the high-pressure micro-flow experimental system includes a high-pressure gas storage tank 1, and a gas tank piston is slidably arranged in the high-pressure gas storage tank 1. 11. One side of the gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com