Preparation method of small-period array structure

A technology with an array structure and a small period, which is applied in the photoplate making process of the pattern surface, photomechanical equipment, microlithography exposure equipment, etc., can solve the problem of slow speed, expensive extreme ultraviolet exposure equipment, and can not meet the needs of scientific research and processing and other issues to achieve the effect of high precision and flexible preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

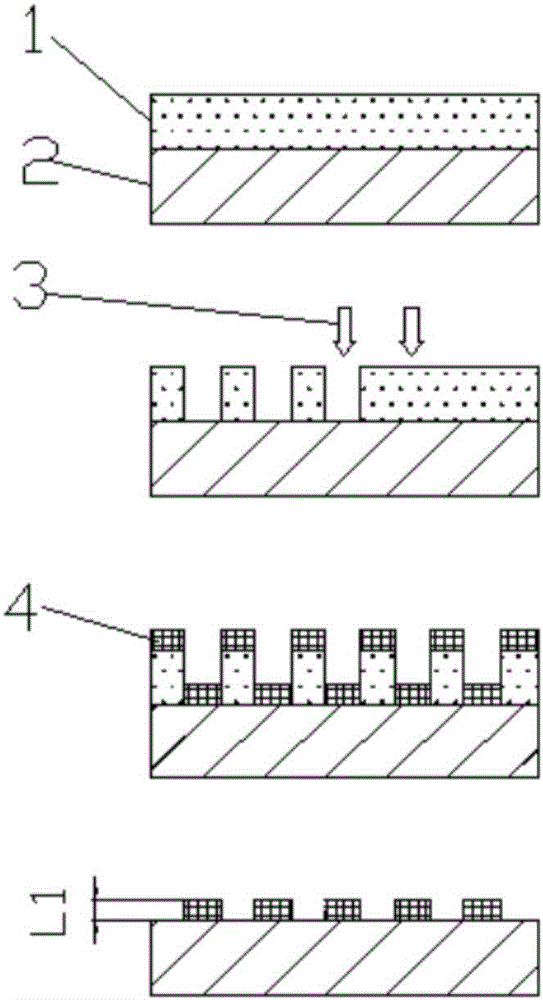

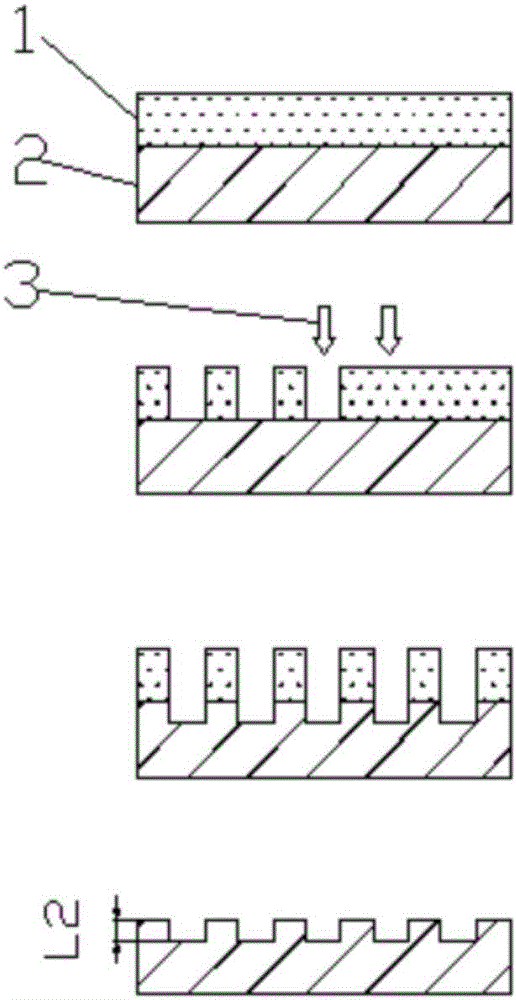

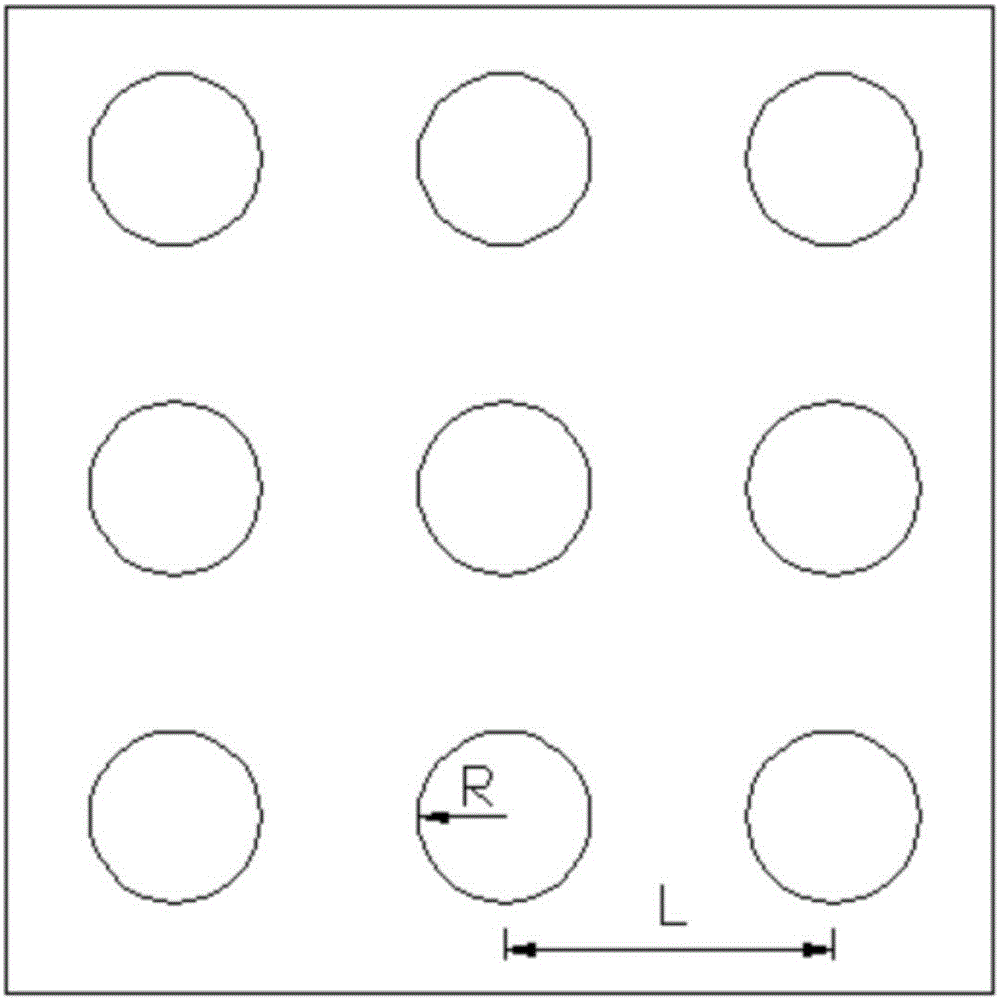

[0034] figure 1 It is a flowchart of a method for preparing a small-period array structure according to an embodiment of the present invention. Such as figure 1 As shown, a preparation method of a small periodic array structure, comprising:

[0035] Step 1: Spin-coat photoresist 1 on substrate 2 .

[0036] The substrate 2 used in step 1 can be a silicon substrate, a silicon dioxide substrate or a sapphire substrate, or a silicon nitride film, a silicon dioxide film or a silicon carbide film grown on the silicon substrate substrate, Any flat substrate with thin-film material that is processed on a flat surface is also possible.

[0037] The photoresist 1 used in step 1 is positive or negative. After the photoresist is exposed to light, it can react quickly in the exposure area, so that the physical properties of this material, especially the solubility and affinity, will change significantly. After being treated with an appropriate solvent, the soluble part will be dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com