Point-contact loosening sandstone core model

A technology of core model and point contact, which is applied in the direction of sampling, measuring device, suspension and porous material analysis, etc., can solve the problems of pipe wall deformation, easy to twist, unfavorable for flow diversion, etc., and achieve strong flow conductivity and bearing capacity The effect of large pressure range and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] (1) Carry out the assembly of the model:

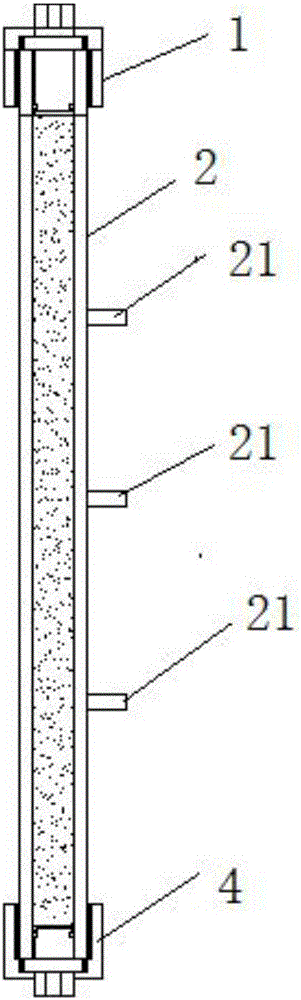

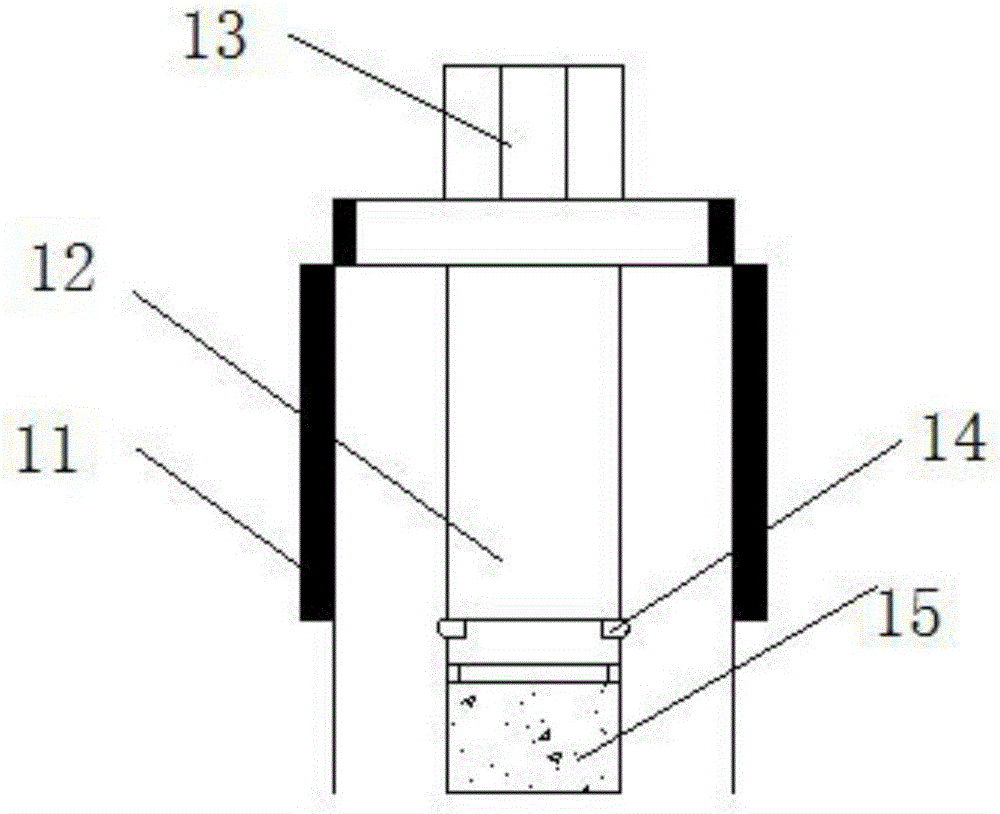

[0052] ①Put on the O-ring, apply lubricating oil, install the filter membrane and the small hole of the ring, install the lower end to the pipe body, and tighten the thread to fix the lower end;

[0053] ②Block the pressure measuring point with wire plug;

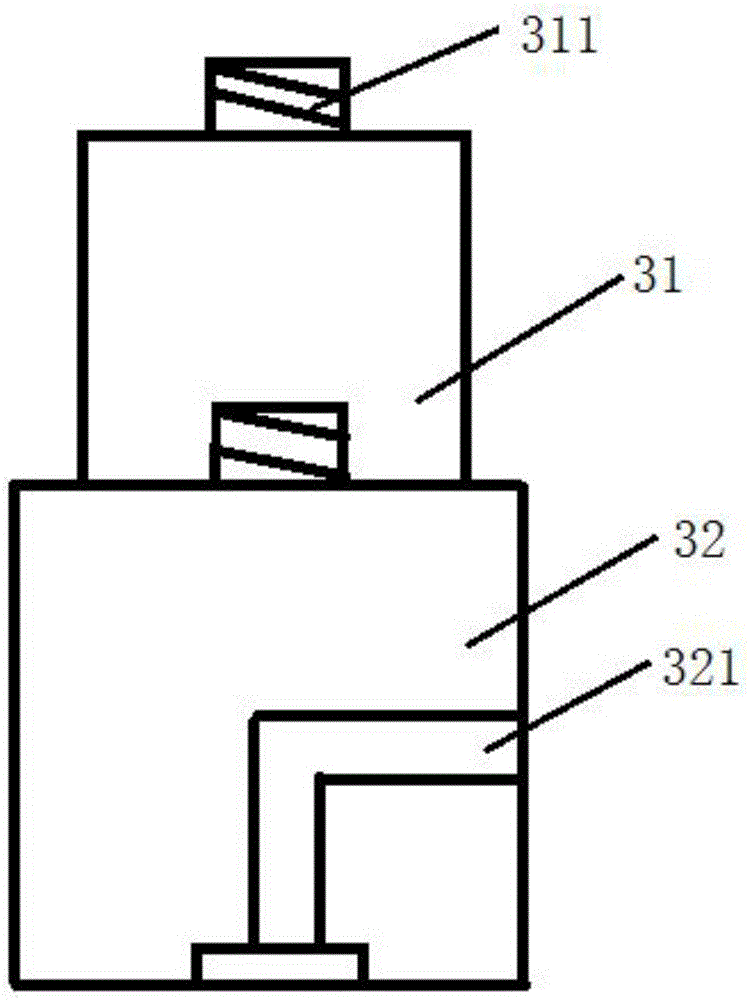

[0054] (2) Carry out sand filling operation. Generally, sand filling is divided into five times, and 80g of quartz sand of different meshes are filled in each time, vibrated with a vibrator for 20s, and after 5 minutes of constant pressure with a pressure column, sand is filled, vibrated, and pressed again, and the last time it is higher than the core surface 2cm can be applied for forging operation (results of multiple tests show that 2cm more sand body is packed, which just makes the core length 50cm), using the corresponding pressing mold at 25MPa constant pressure for 5 minutes, and finally putting it into the long end after constant pressure of 5MPa, Carry out mold co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com