Miniature wing surface electric heating deicing system icing wind tunnel test device

An ice wind tunnel and electric heating technology, applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problem of unusable, determining the initial windward angle of the sample, and the inability to connect small airfoil samples, etc. problem, to achieve the effect of strong anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

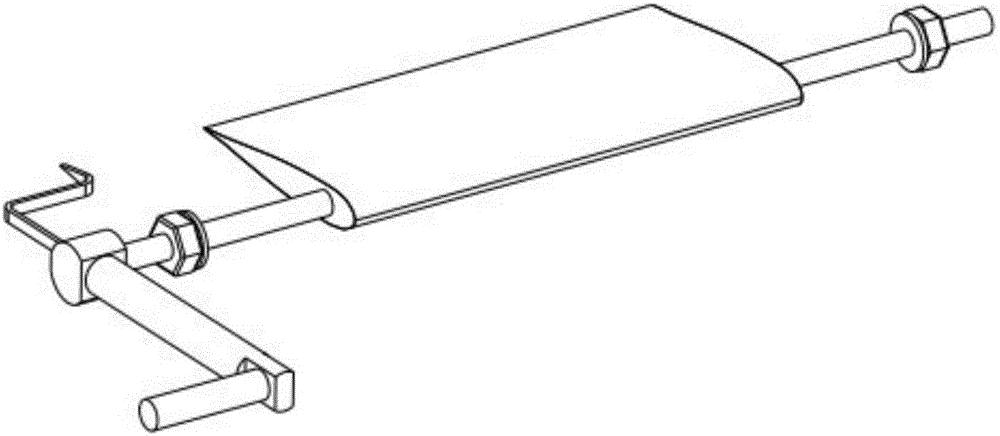

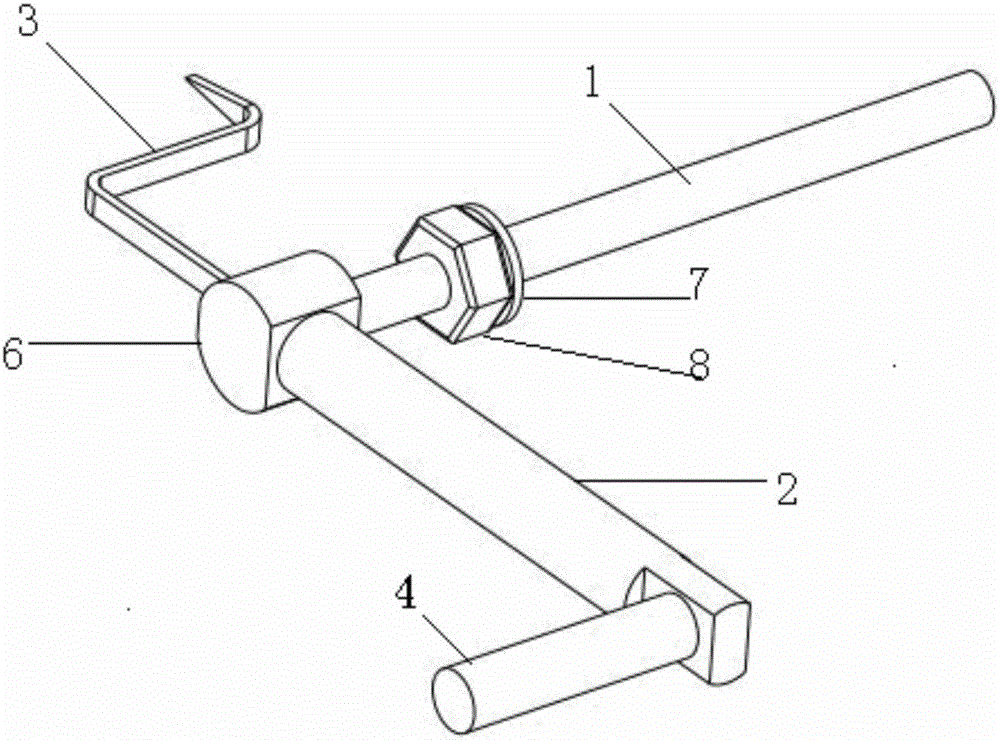

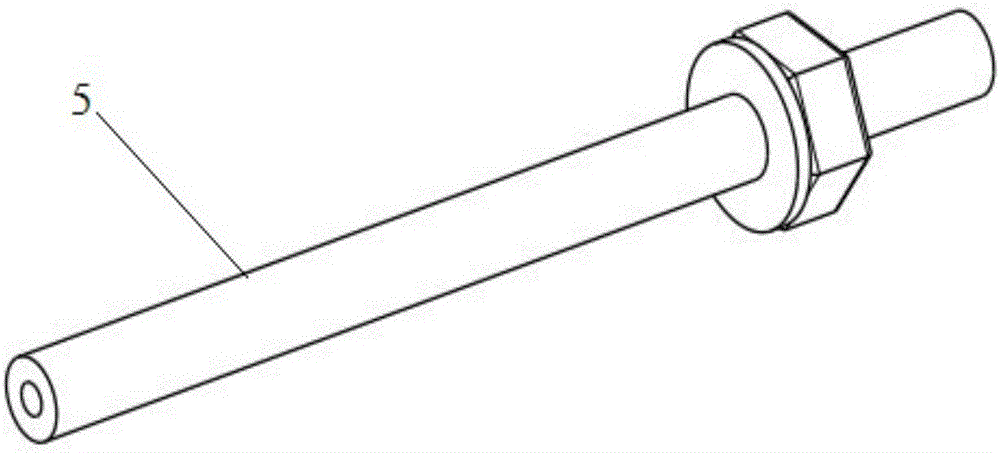

[0023] This embodiment is a small airfoil electric heating deicing system ice wind tunnel test device.

[0024] refer to Figure 1 to Figure 5 , the ice wind tunnel test device of the small airfoil electric heating deicing system of the present embodiment is composed of the ice wind tunnel side wall 9, the small wing sample 10 and the connecting rod 1, the rocker arm 2, the Z-shaped pointer 3, the handle 4, the hollow connection Composed of rod 5, adapter 6, self-locking gasket 7, and fastening nut 8, connecting rod 1 and hollow connecting rod 5 are connected with small wing sample 10, which is located between the side walls of the side ice wind tunnel, Coaxial round holes are processed on the side walls 9 of the two ice wind tunnels, and the outer wall surface of the side walls of the ice wind tunnel that cooperates with the connecting rod 1 is marked with a corner scale along the circumference of the holes, and the rocker arm 2 and the Z-shaped pointer 3 pass through the ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com