Frost resistance water meter

A water meter and movement technology, which is applied in measuring devices, instruments, liquid/fluid solid measurement, etc., can solve problems such as low glass strength, and achieve the effect of avoiding freezing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

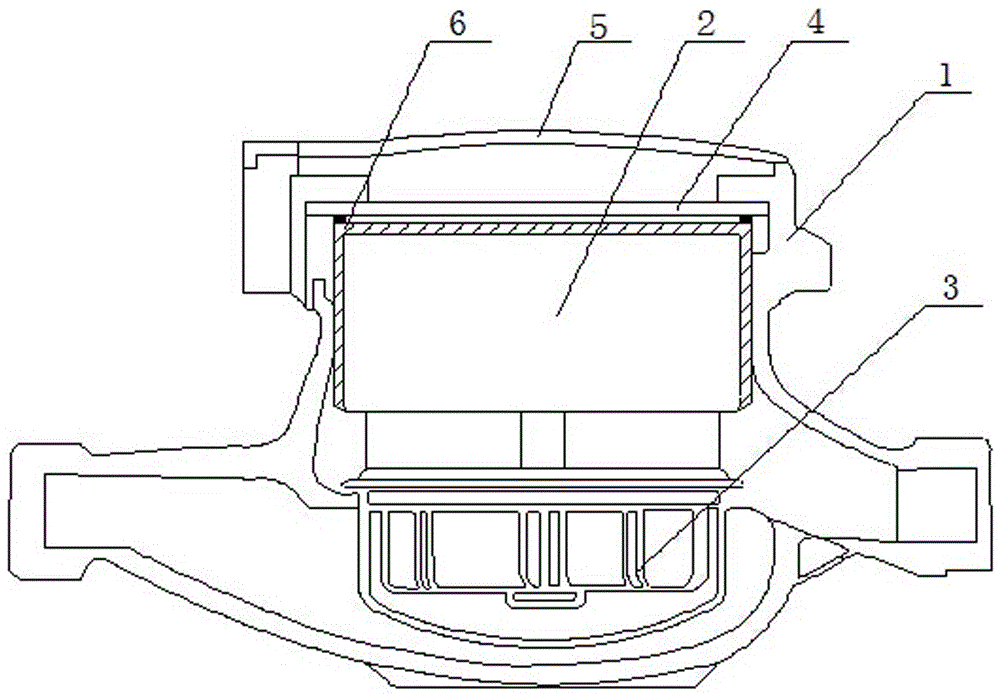

[0016] Such as figure 1 As shown, in the case of the existing water meter structure, (the existing water meter includes a housing 1, a core 2 placed in the housing 1, an impeller assembly 3 connected to the core 2, and a Table glass plate 4 and flip cover 5), an airtight inverted U-shaped transparent cover 6 made of hard transparent plastic is buckled outside the movement, so that the air in the top of the water meter and the movement cannot be discharged from the top of the movement. Water enters from the water inlet of the water meter and flows quickly to the water outlet. At this time, since the air in the lower part of the water meter and the movement cannot be discharged from the upper part of the movement, a water-sealed air is formed in the transparent cover (ie, the upper part of the movement). Cavity, that is, the gas-liquid balance is realized in the water meter, so that water cannot enter the upper part of the movement (generally, the water level is below the dial)....

Embodiment 2

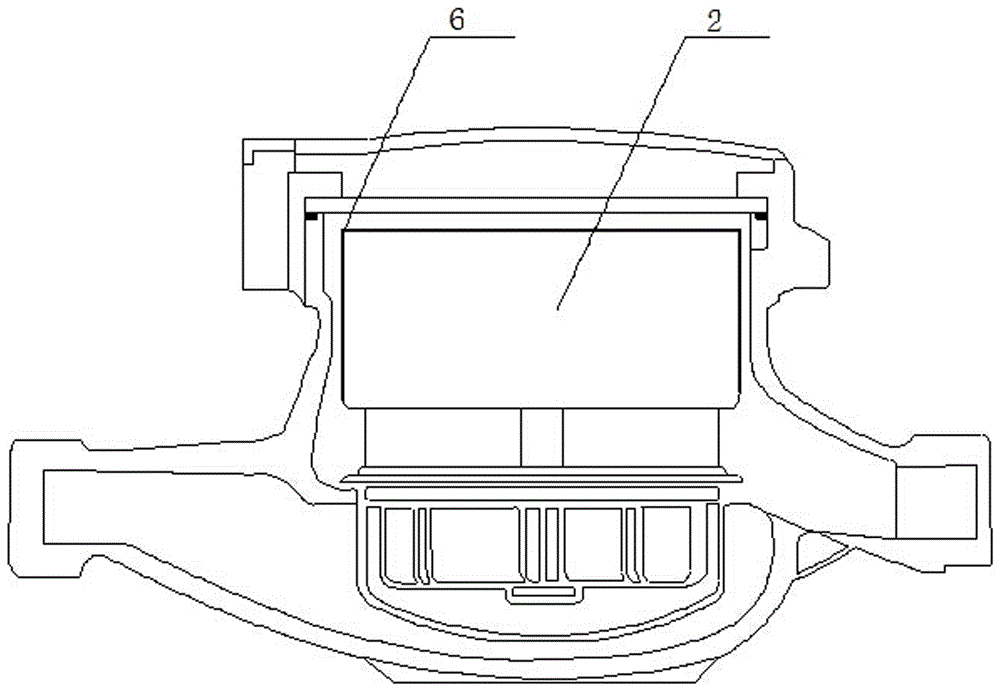

[0018] Such as figure 2 As shown, the inverted U-shaped transparent cover 6 is made of heat-shrinkable film, and the inverted U-shaped transparent cover is closely attached to the outside of the movement 2 .

[0019] Other structures are with embodiment 1.

Embodiment 3

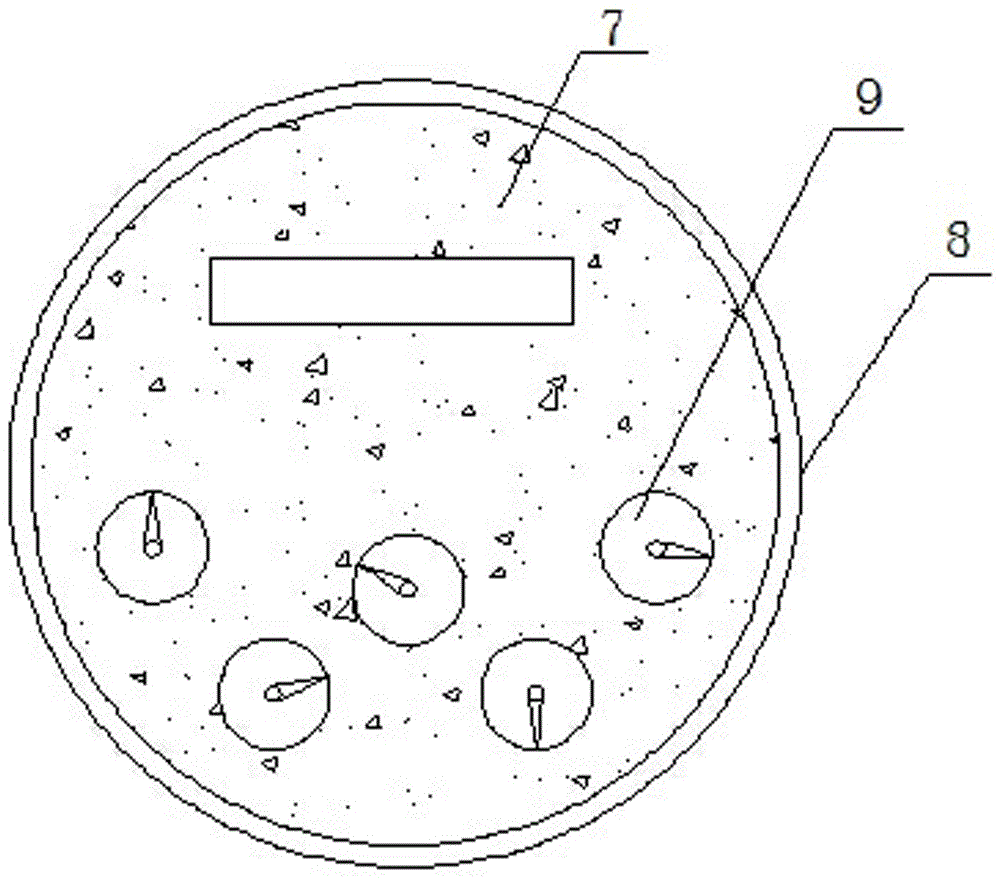

[0021] Such as image 3 As shown, the top of the movement is a dial 8, and the gap between the pointer 9 and the pointer 9 is filled with a high foaming polymer 7 inside the dial 8 to ensure the proportion of air inside the movement. When the inverted U-shaped transparent cover fails, the high-foaming polymer 7 can absorb the expansion force when water becomes solid, so as to prevent the watch glass from being damaged by freezing.

[0022] It should be noted here that the top of the movement and the bottom of the dial can also be filled with gas-containing polymers or aerosols to increase the gas content inside the movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com