MEMS gyroscope test device, system and method

A test device and test system technology, applied in the direction of measurement devices, instruments, etc., can solve the problems of reducing the signal-to-noise ratio of useful signals, unable to obtain measurement results, and large error in test results, and achieves improved measurement accuracy, improved anti-interference ability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical scheme of the present invention is described in further detail below in conjunction with accompanying drawing:

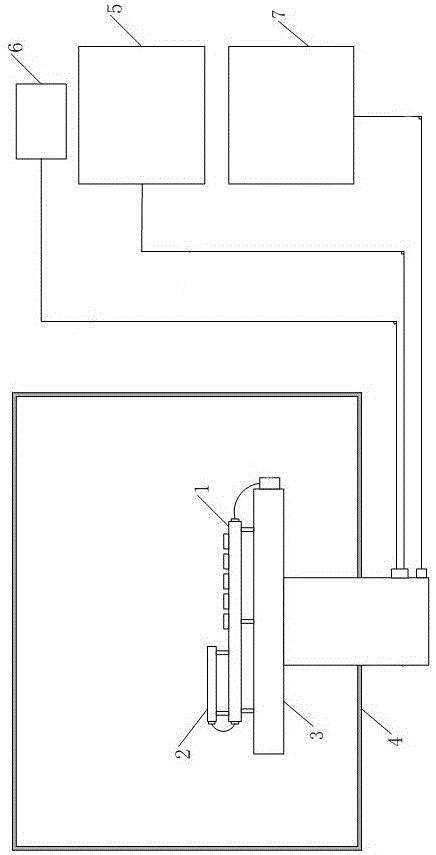

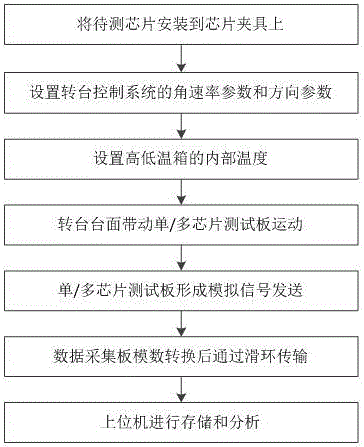

[0042] like figure 1As shown, Embodiment 1 discloses a MEMS gyroscope test device, including a high and low temperature box 4, and the inside of the high and low temperature box 4 is provided with a turntable table 3, a temperature control system, a slip ring and a single / multi-chip test board 1 , the outside of the high and low temperature box 4 is provided with a drive motor and a turntable control system 7, the turntable control system 7 controls the rotation direction and speed of the turntable table 3 through the drive motor, and the single / multi-chip test board 1 Installed on the turntable table top 3, the single / multi-chip test board 1 is provided with chip fixtures, the temperature control system controls the temperature inside the high and low temperature box 4; the inside of the high and low temperature box 4 is also provided with data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com