Blade shape rapid scanning device and method

A technology of fast scanning and leaf shape, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of insufficient precision, low detection efficiency, and long time consumption, so as to improve measurement accuracy, high-precision fast scanning, and overcome dependence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

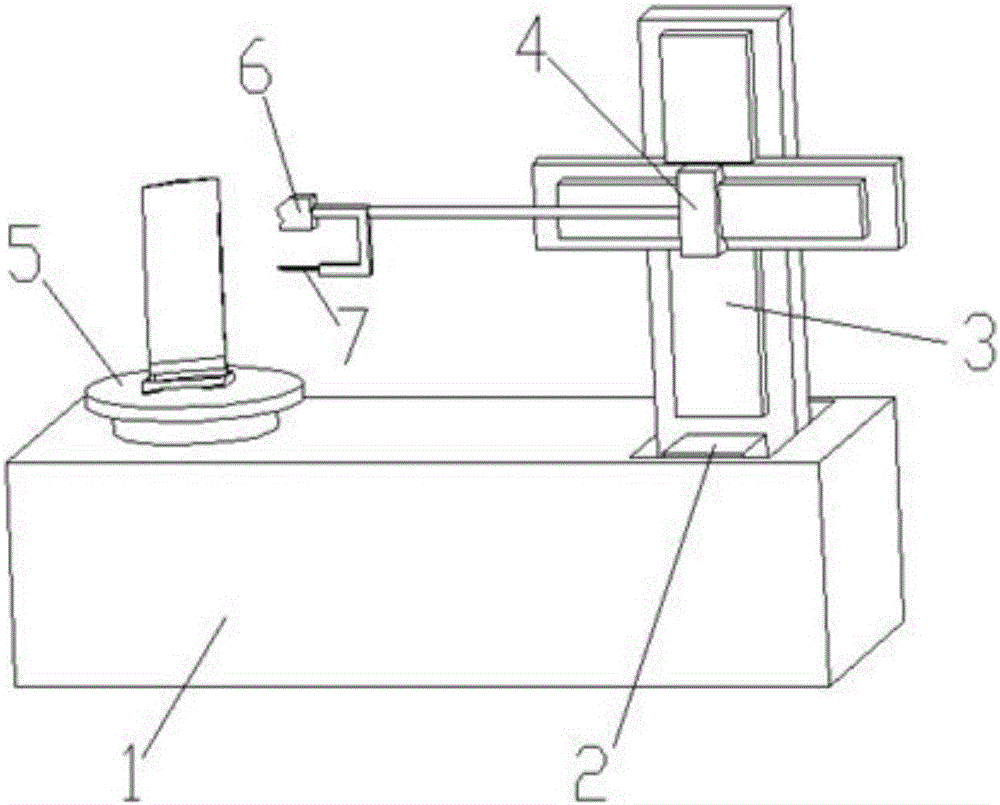

[0022] Such as figure 1 As shown, a blade shape rapid scanning device is characterized in that it includes a base 1 , an X spindle 2 , a Y spindle 4 , a Z spindle 3 , a turntable 5 , a non-contact optical probe 6 and a contact probe 7 . The X spindle 2 , the Y spindle 4 , the Z spindle 3 and the turntable 5 are installed on the base 1 . in,

[0023] The X, Y, and Z spindles are used to drive the probe to move freely in the three directions of space X, Y, and Z;

[0024] The turntable 5 is used to drive the blades to rotate in the measurement space;

[0025] The non-contact optical measuring head 6 and the contact measuring head 7 are jointly installed on the Y-axis 4 through a connecting piece. The non-contact optical measuring head 6 is used to measure the surface of the blade with low precision, obtain all the point cloud data of the blade and plan the measurement path. The contact probe 7 is used to measure the surface of the blade with high precision along the planned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com