Caliper

A logging tool and outer casing technology, which is applied in the direction of wellbore/well components, measurement, earthwork drilling and production, etc. It can solve problems such as inaccurate data, affecting the progress of the project, and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

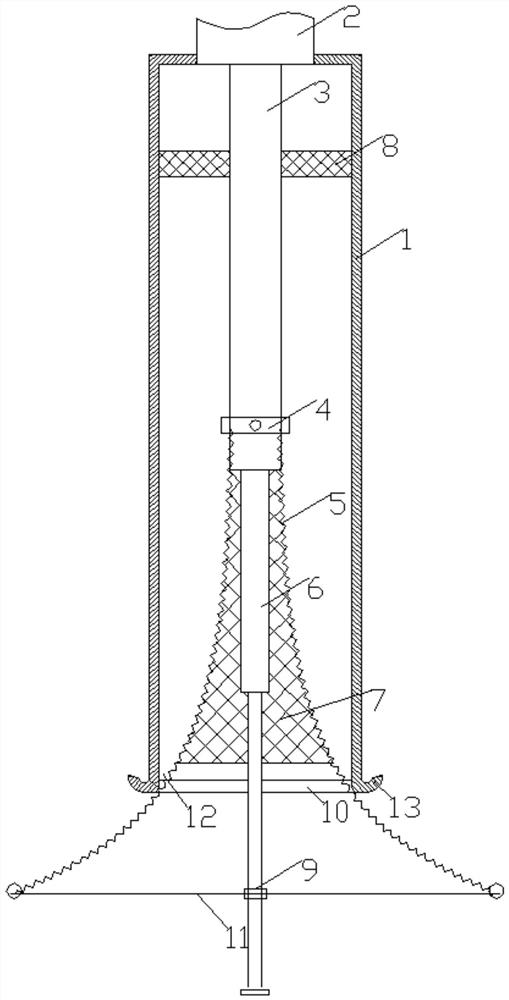

[0021] like figure 1 As shown, the caliper logging instrument includes an outer sleeve 1 and a main telescopic rod 3, the main telescopic rod 3 is installed in the outer sleeve 1, the main telescopic rod 3 is coaxial with the outer sleeve 1, and the main telescopic rod 3 is coaxial with the outer sleeve 1. The rod 3 is controlled by the telescopic controller 2; the telescopic controller 2 is installed on the top of the outer sleeve 1; there is a guide block 8 inside the outer sleeve 1, and there are through holes in the guide block 8 for The main telescopic rod 3 passes through; the lower end of the outer sleeve 1 is an open end 10;

[0022] The outer wall of the main telescopic rod 3 is equipped with a fixed ring 4; it also includes a plurality of elongated elastic reeds 5, one end of the reed 5 is fixed on the fixed ring 4, and the other end is equipped with a ball 12; The reeds 5 are distributed symmetrically around the main telescopic rod 3, and the reeds 5 are arc-shaped...

Embodiment 2

[0028] In order to ensure the stability of each reed 5 being folded and released, on the basis of Embodiment 1, the following technical features are also included:

[0029] The lower end of the main telescopic rod 3 is connected to the central rod 6, and the central rod 6 is covered with a collar 9, and the collar 9 can slide on the central rod 6; each of the balls 12 is respectively connected to a Root elastic cord 11, the other end of elastic cord 11 is fixed on the collar 9.

[0030] The elastic cord 11 can constrain the reed 5 to stretch out too long, which will affect the measurement effect. And contribute to the retraction of reed 5 and ball 12. Elastic rope 11 can also keep each reed 5 to protrude the same as far as possible in addition, and central rod 6 can be positioned at the center line of well as far as possible, guarantees the accuracy of measurement.

Embodiment 3

[0032] When used to measure the position close to the bottom of the well, since the reed 5 is stretched out, it is turned outwards, and the ball 12 is also close to the bottom of the well, in order to prevent the center rod 6 from pressing against the bottom of the well, the ball 12 cannot be attached to the bottom of the well. Therefore, in the technical solution of Embodiment 2, the central rod 6 is designed to be a telescopic rod, including multiple sleeve rods with gradually changing diameters. set of poles. like image 3 As shown, when hitting the bottom, the central rod 6 is retracted to ensure that the ball 12 is attached to the bottom of the well for measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com