Construction method for excavating upper drift heading and lower drift heading in two side walls of ultra-large subsurface tunnel

A construction method and double-side wall technology, applied in the field of construction engineering, can solve problems such as high risk and complex construction environment, and achieve the effect of low unit consumption of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

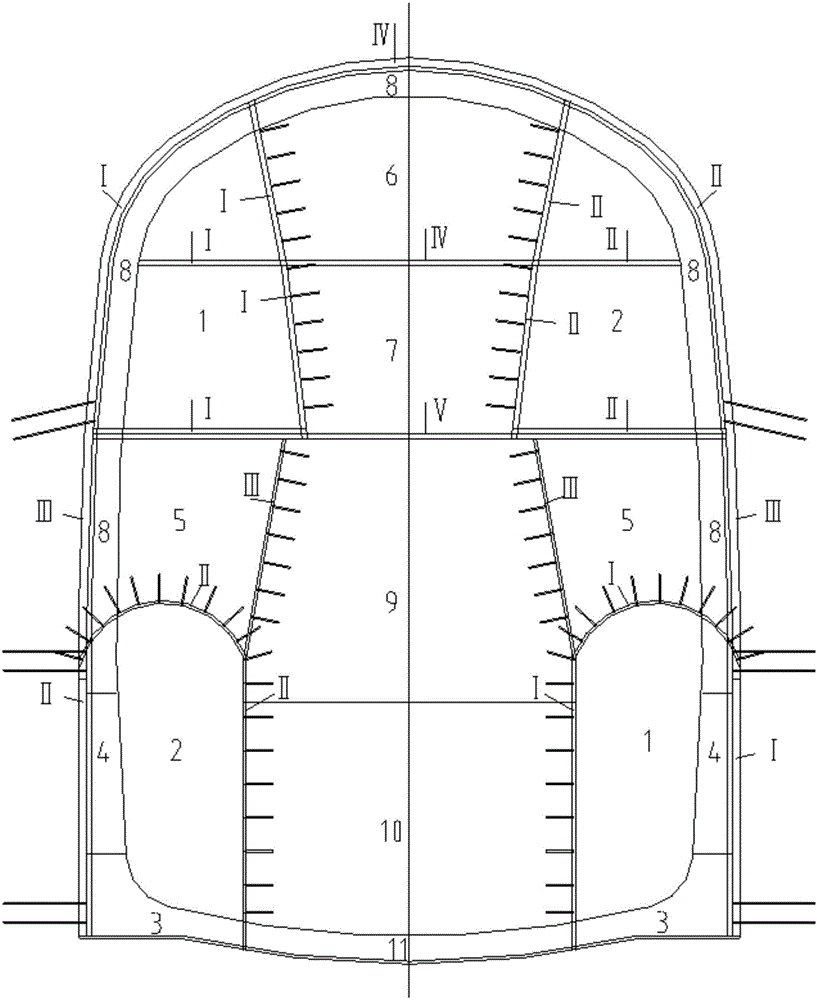

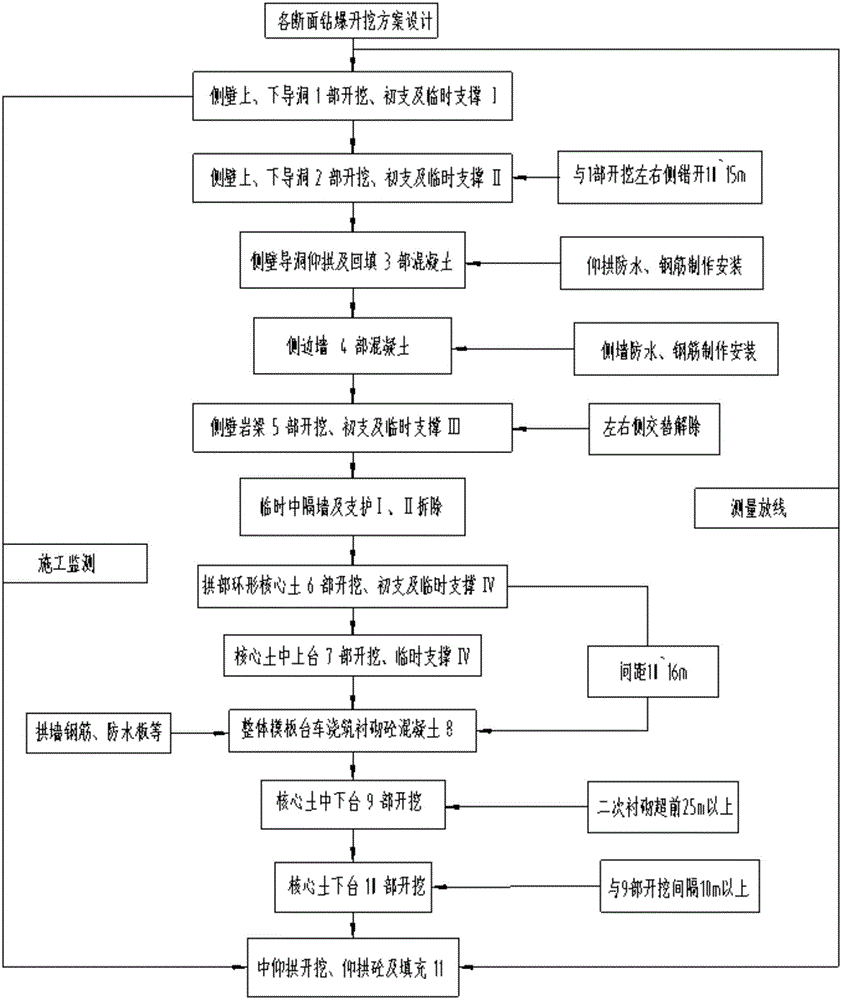

[0071] Below in conjunction with accompanying drawing, the excavation construction method of the upper and lower guide pits of the double side wall of the ultra-large underground excavation tunnel of the present invention is described in detail below.

[0072] As shown in the accompanying drawings, the construction method for excavating the upper and lower guide pits of the double side walls of the ultra-large underground excavation tunnel of the present invention: the method includes:

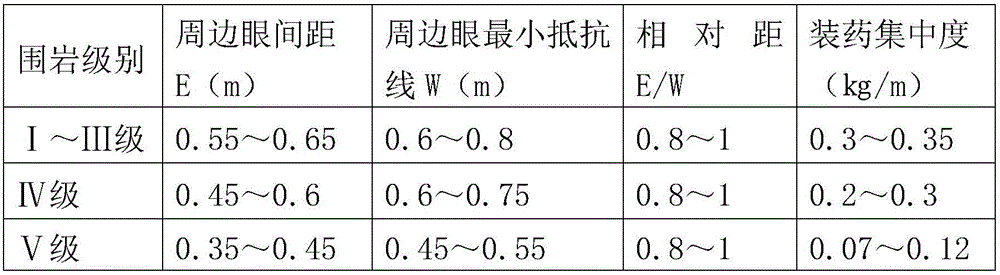

[0073] A. Drilling and blasting scheme design

[0074] a. Drilling and blasting design and construction requirements

[0075] The environment of super-large-section tunnels is complex and the construction is difficult. The blasting design of tunnels must ensure high-quality tunnel excavation sections and footage while controlling the blasting vibrations within as small a range as possible to ensure the safety and protection of the ground surface and buildings. The influence of the surrounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com