A diversion shell type two-stage double-suction centrifugal pump

A technology of a guide shell and a centrifugal pump, which is applied to the components of a pumping device for elastic fluid, a non-variable-capacity pump, a radial flow pump, etc. Due to the small axial size of the radial guide vanes and the huge size of the bridge, the effects of strong cavitation resistance, wide flow channel and small lift are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

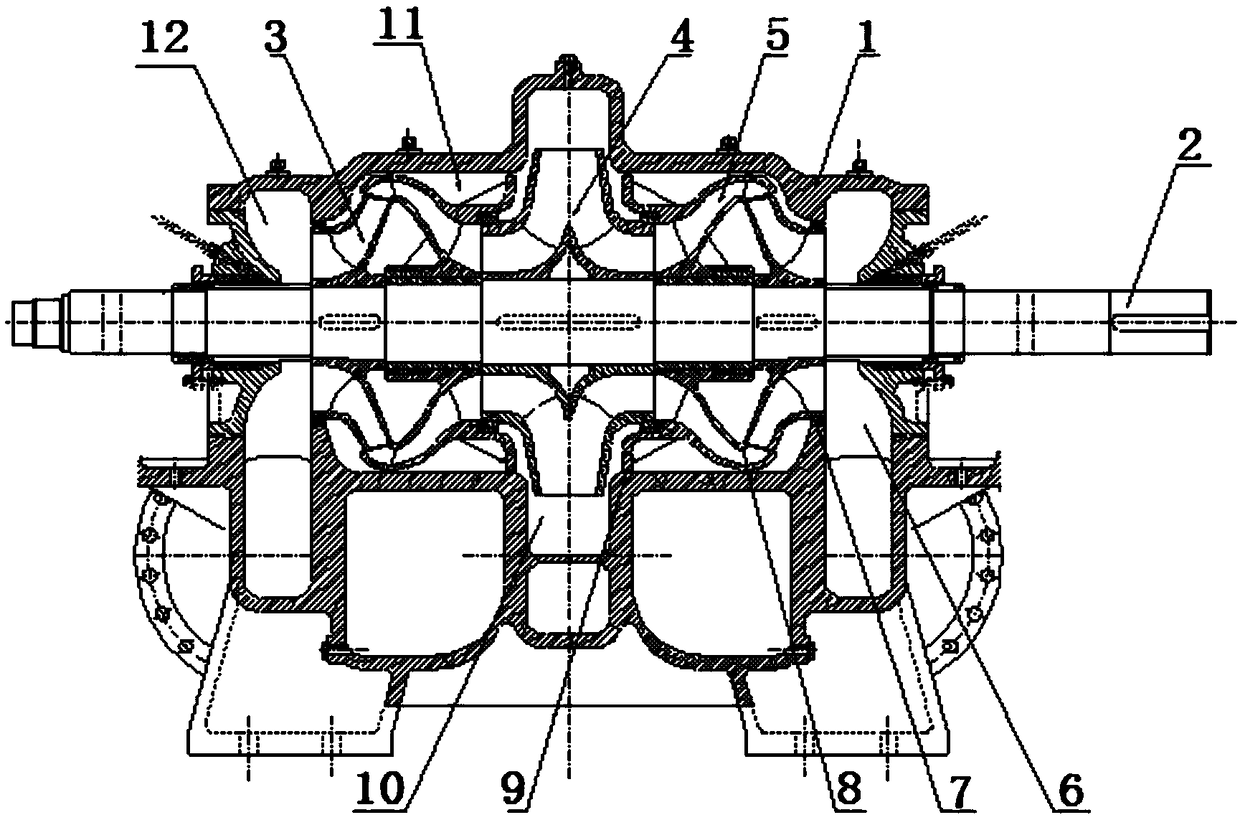

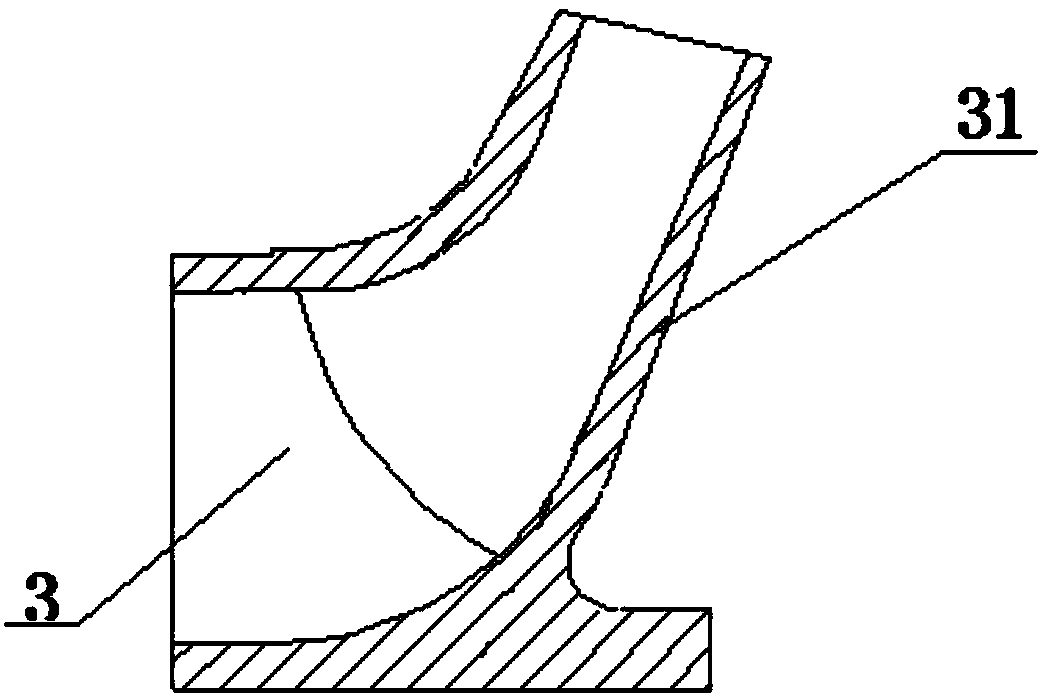

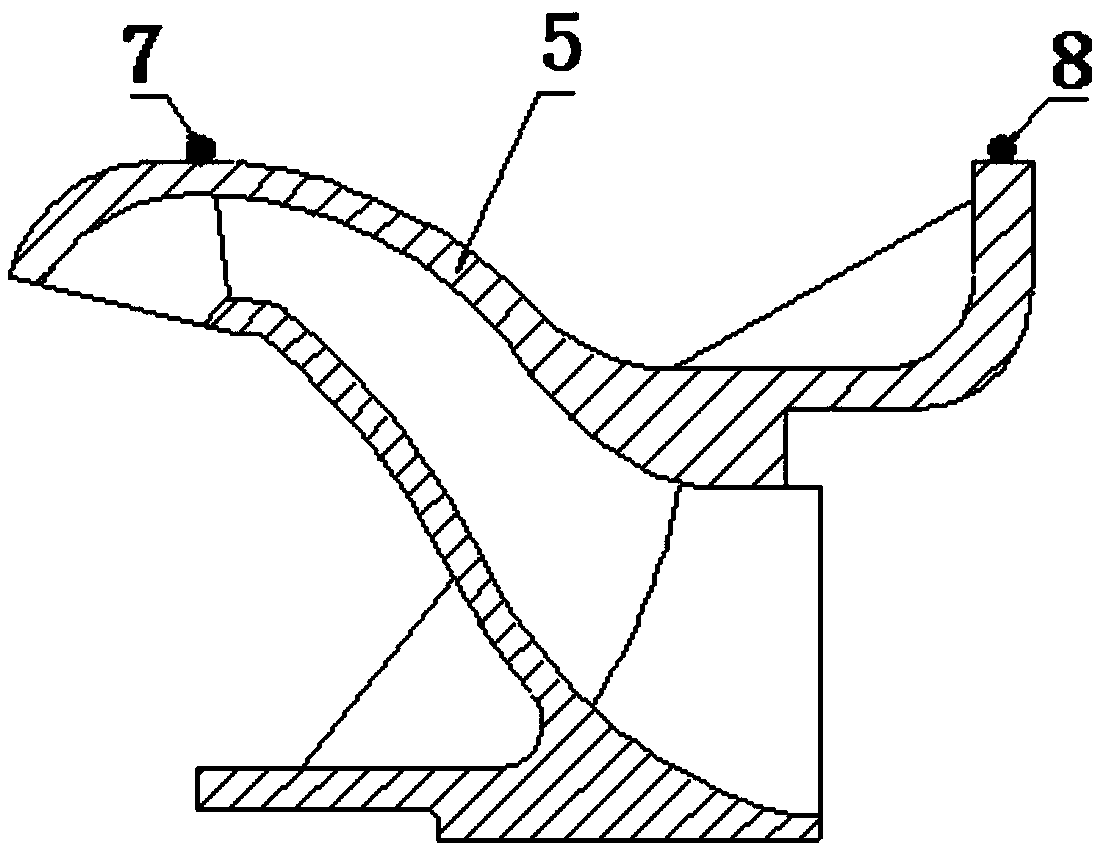

[0031] like Figure 1~3 As shown, the present invention proposes a diversion casing type double-stage double-suction centrifugal pump, which includes a pump body 1 and a transmission shaft 2 that runs through the pump body 1 and is rotatably connected with the pump body 1. Two first-stage impellers 3 are arranged at intervals on the transmission shaft 2, a second-stage impeller 4 is arranged on the transmission shaft 2 between the two first-stage impellers 3, and an interstage guide casing is fixedly arranged in the pump body 1. 5. The interstage diversion shell 5 is an impeller, its flow channel is S-shaped, the flow channel is wide and the turning is smooth, it is located between the first stage impeller 3 and the second stage impeller 4, the inlet end of the interstage diversion shell 5 and The outlet end of the first-stage impeller 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com