LCW light combined wallboard and production technique thereof

A wallboard and lightweight technology, applied in building materials, building components, buildings, etc., can solve the problems of inability to reduce production costs, complex frame processing technology, inability to automate or semi-automatic production, etc., to improve force resistance, increase The effect of force strength and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

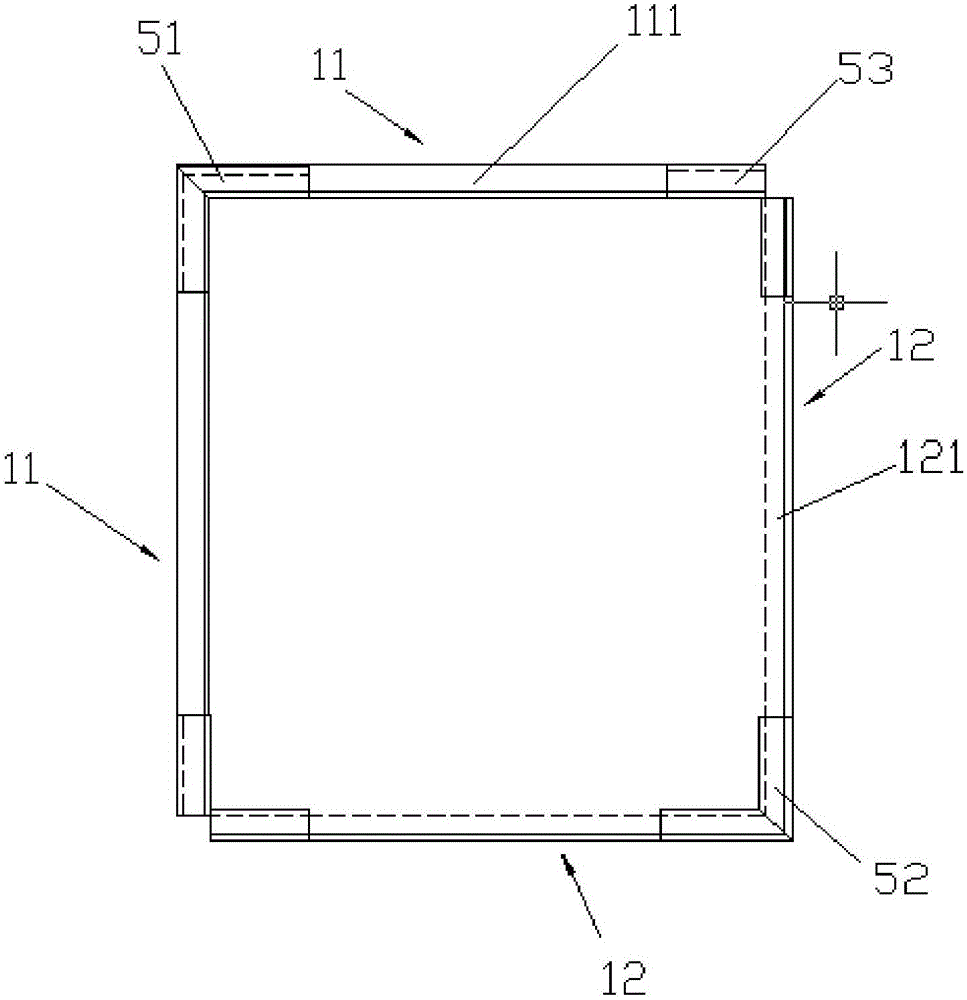

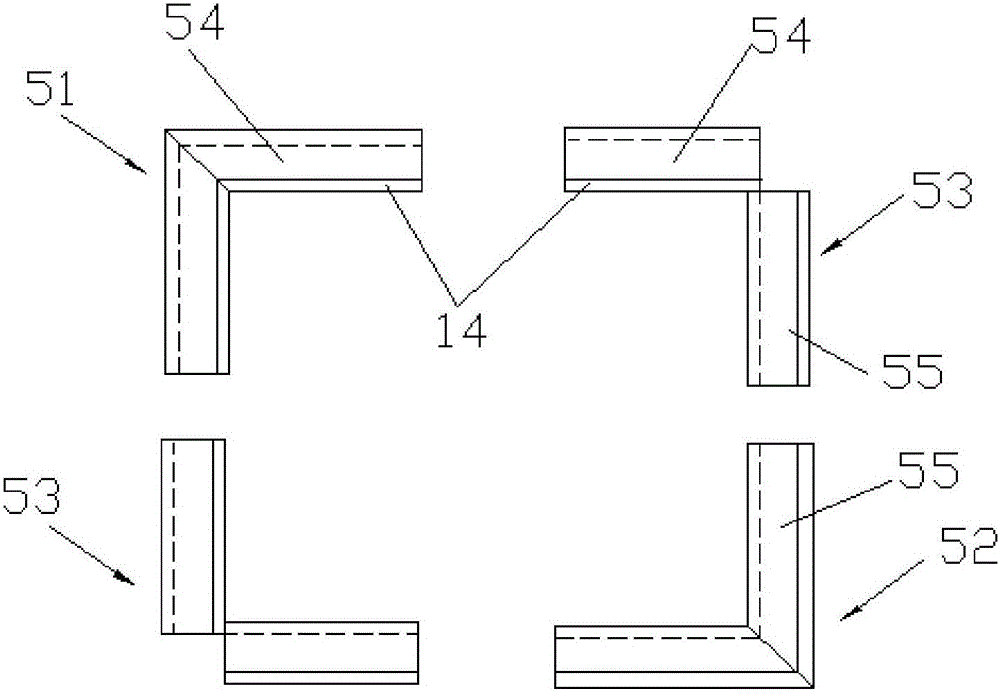

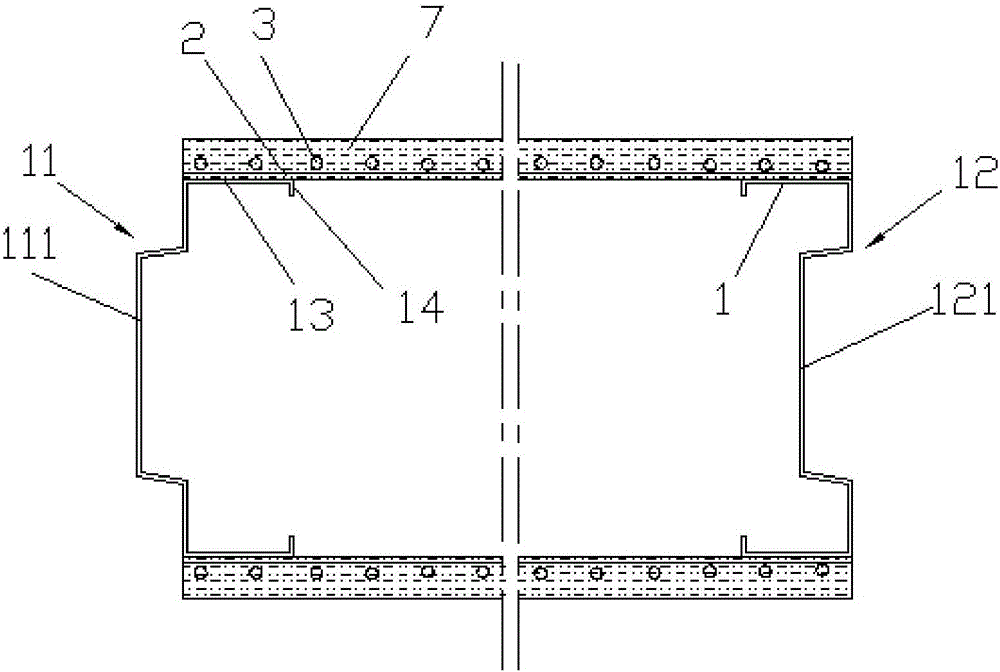

[0027] Embodiment 1: as Figure 1 to Figure 3 As shown, a kind of LCW light composite wallboard (lightweight composite wallboard for anti-seismic and thermal insulation), including a rectangular frame 1, a sprayed grouting net 2, a reinforced mesh 3 and a surface layer, a sprayed grouted mesh 2, a reinforced reinforced mesh 3 The surface layer is located on both sides of the frame 1 from the inside to the outside. The shotcrete mesh 2 is connected with the steel bar stress mesh 3 and connected with the frame 1. The shotcrete mesh 2 is used for spraying concrete to form a surface layer or attach a composite surface layer. The reinforcing bar diameter of reinforcing bar stress net 3 is bigger, can improve the stress strength of wallboard, and steel bar stress net 3 is the stress bar that frame 1 connects with surface layer lightweight concrete 7, improves the overall stress of wallboard.

[0028] The frame 1 is assembled by plugging two convex profiles 11, two concave profiles 1...

Embodiment 2

[0030] Embodiment 2: the frame of this embodiment 1 is the same as that of embodiment 1, the difference is as follows Figure 4 As shown, it also includes a lightweight filling board 4, but there is no shotcrete net. The lightweight filling board 4 is located between two combined steel wire meshes. The surface layer is fine stone concrete or lightweight concrete surface layer, and the lightweight filling board is installed Board 4 can improve the effect of sound insulation and heat insulation. In this embodiment, the lightweight filling board 4 with higher strength is selected, so that the sprayed grouting net can not be installed. Connect the two with the steel bar stress net 3 and form the surface layer. The combined steel mesh is formed by connecting the reinforced mesh 3 and the anti-cracking steel mesh 6, and the reinforced mesh 3 is wave-shaped to improve the strength of the mesh panel, which is conducive to improving the strength of the entire wallboard. The reinforce...

Embodiment 3

[0031] Embodiment 3: the frame of this embodiment 1 is the same as that of embodiment 2, the difference is as follows Figure 4 As shown, a shotcrete net is also provided, and the shotcrete net 2 is connected with the lightweight fill plate 4 by an iron wire 41 passing through the lightweight filling plate 4 , and there is an interval between the shotcrete net 2 and the steel bar stress net 3 . This interval makes the surface layer lightweight concrete 7 can completely wrap the steel bar stress net 3 or the steel bar stress net 3 and the anti-cracking steel wire net 6, which improves the overall structural strength of the wallboard. The spacer between the pulp net 2 and the reinforced net 3 keeps this interval.

[0032] The manufacturing method of the LCW light composite wallboard described in Embodiment 3 includes the following steps: the manufacturing process includes the following steps: (1), two convex profiles 11 are intersected at right angles with a convex groove corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com