An assembled energy-dissipating beam-column joint

A beam-column joint and assembly technology, applied in protected buildings/shelters, building types, buildings, etc., can solve problems such as structural damage, inoperability, and huge maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

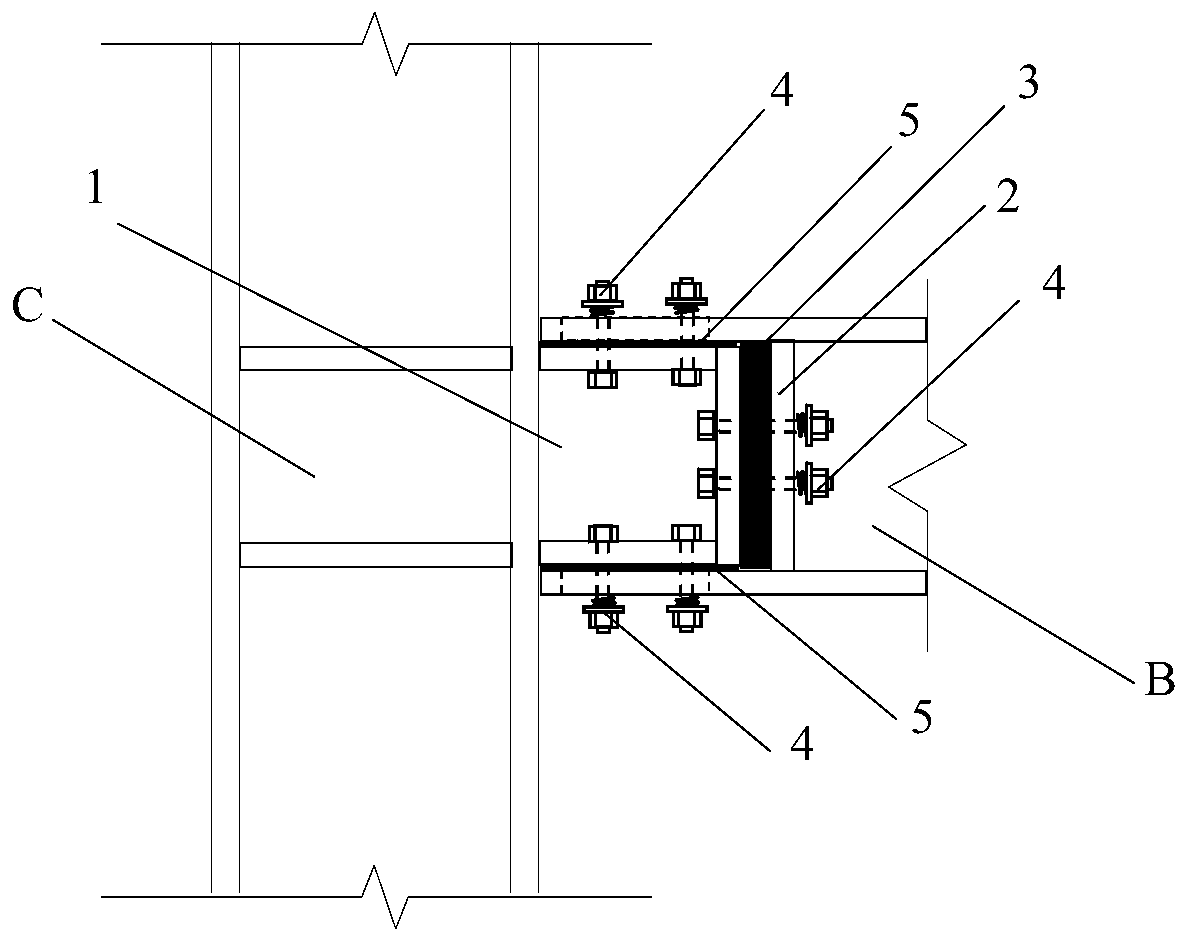

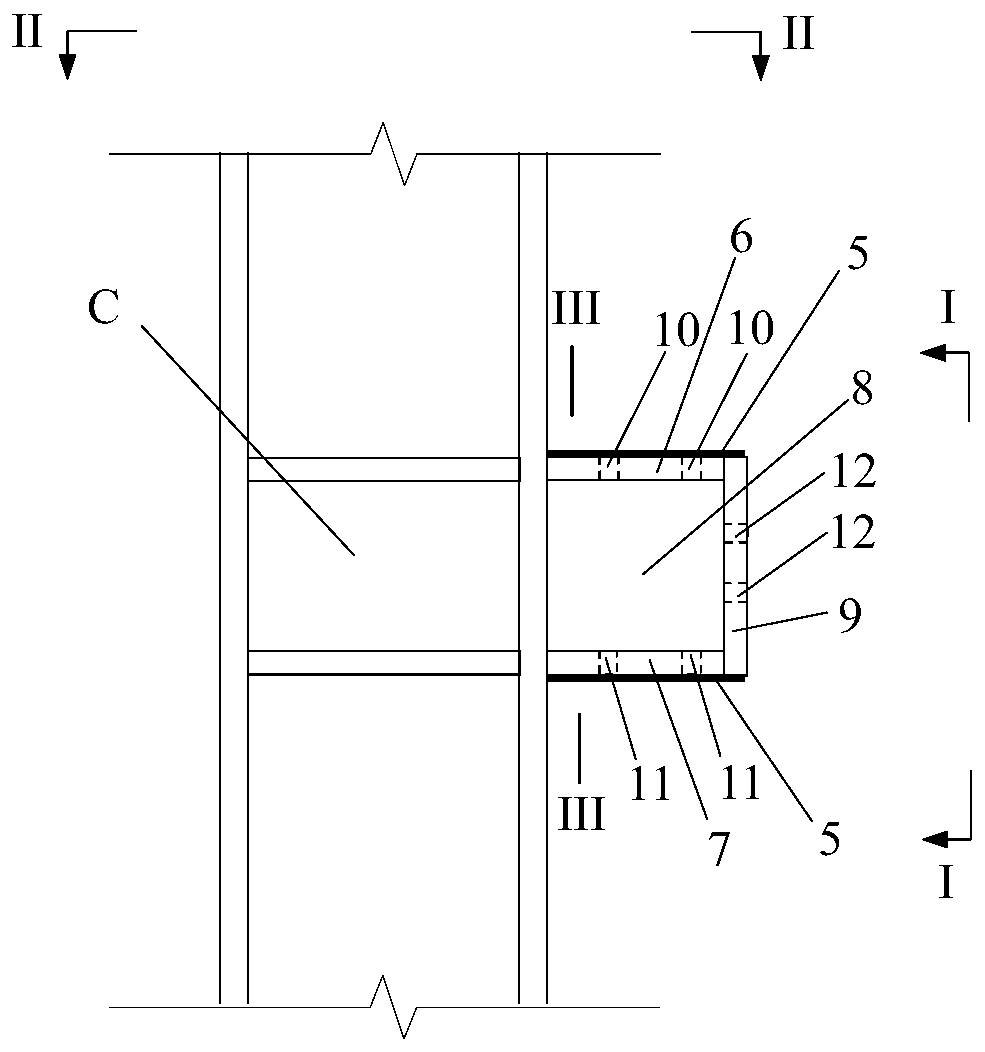

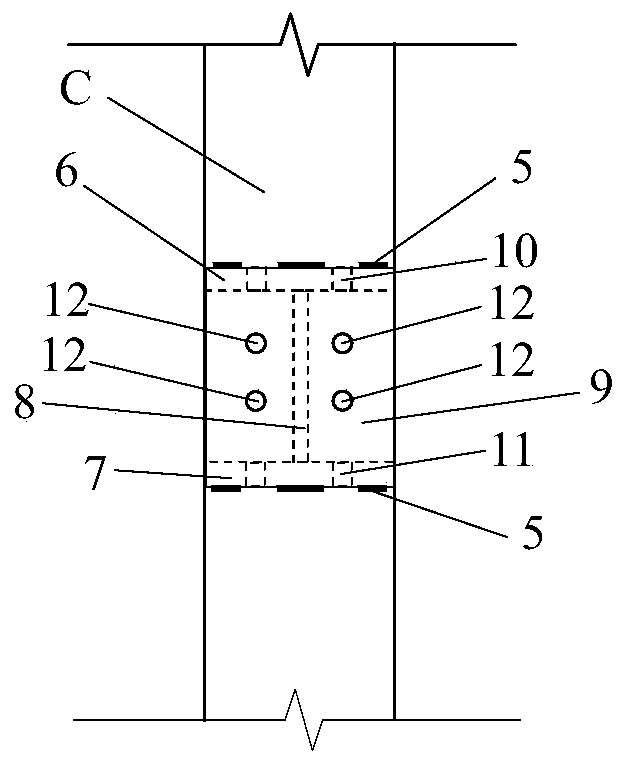

[0021] refer to Figure 1-8 , this embodiment includes a cantilever convex section 1 welded on the column C, a beam end notch 2, a rubber pad 3, and a bolt connection pair 4. The cantilever convex section 1, beam end notch 2, and rubber pad 3 are connected by bolts 4 connected as a whole; the cantilever convex section welded on the column C is composed of the upper flange 6, the lower flange 7, the web 8, the end plate 9 and the friction between the upper surface of the upper flange and the lower surface of the lower flange. The element 5 (made of viscoelastic material), the upper flange 6, the lower flange 7, and the web 8 are welded to form an I-shaped section, and the end plate 9 is connected to the upper flange 6, the lower flange 7, The web 8 is welded and connected, the upper flange 6 has a circular bolt hole 10, the lower flange 7 has a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com