Cable explosion-proof manhole cover

A manhole cover and cable technology, applied in construction, artificial islands, infrastructure engineering, etc., can solve problems such as weak cable joints and cable systems, failure to meet factory quality control requirements, etc., and achieve superior fire protection, low cost, and high temperature resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

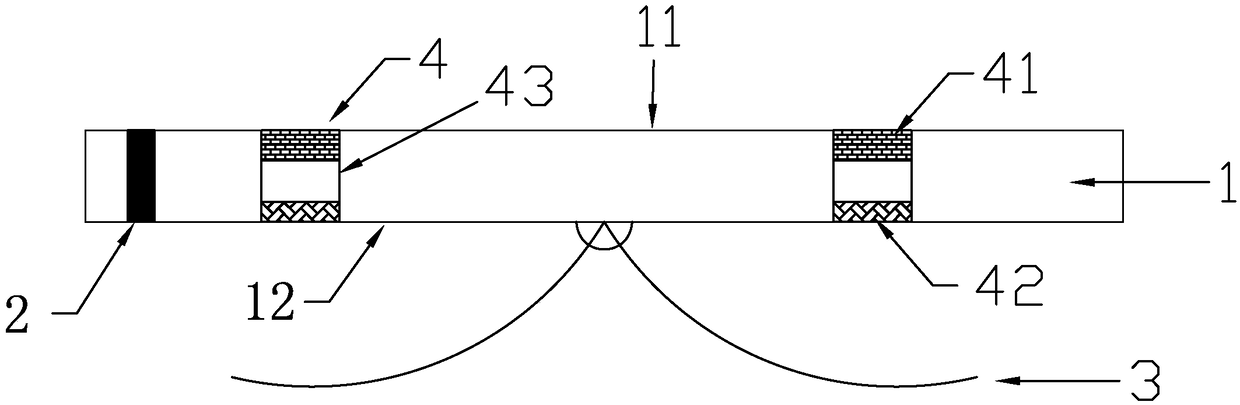

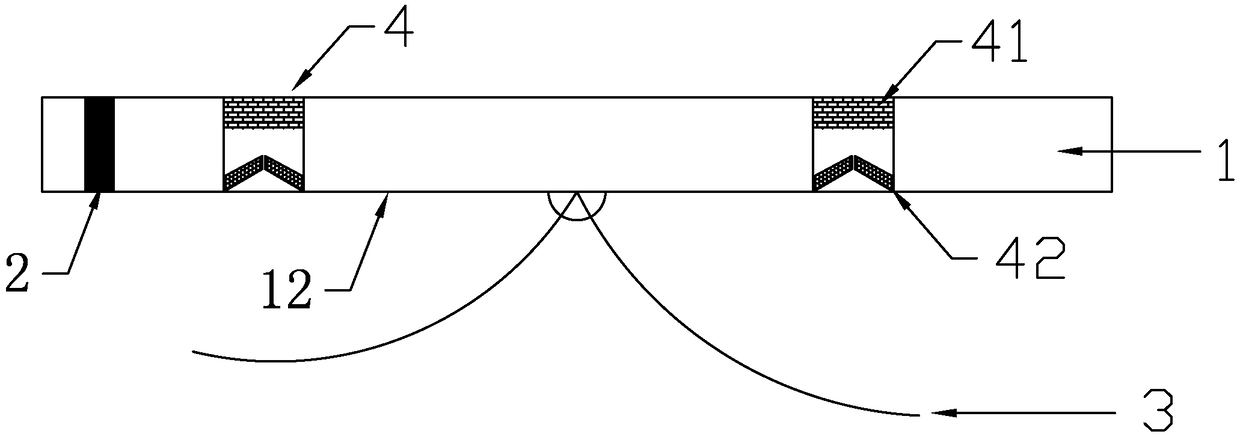

[0024] Such as figure 1 and figure 2 As shown, a cable explosion-proof well cover includes a well cover main body 1. One side of the well cover main body 1 is provided with an attachment structure that can be attached to the wellhead of the well base, and the other side of the well cover main body is provided. Locking structure 2, if the attachment structure and locking structure 2 adopt the structure of the existing manhole cover; the main body of the manhole cover is provided with a vent hole 4 that runs through the front and back, and at least one steel mesh is arranged in the vent hole 4 of the manhole cover main body 1 The rupture layer 42 that can be ruptured by air pressure when grid 41 and an explosion, the reinforcement grid 41 periphery and the well cover main body vent hole inner wall 43 are fixedly connected together, and the rupture layer 42 is fixedly closed vent hole 4.

[0025] In this embodiment, the reinforcement grid 41 is fixedly arranged in the port corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com