Automatic brazing rod changing method based on machine vision

A machine vision and automatic technology, applied in blast furnace parts, furnaces, blast furnace details, etc., can solve the problems of skewed drill rods, mechanical gripping arms not running in place, and mechanical gripping arms cannot normally grip drill rods, etc., to improve mechanization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

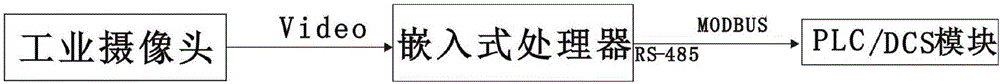

[0021] A method for automatically changing brazing based on machine vision, comprising the following steps:

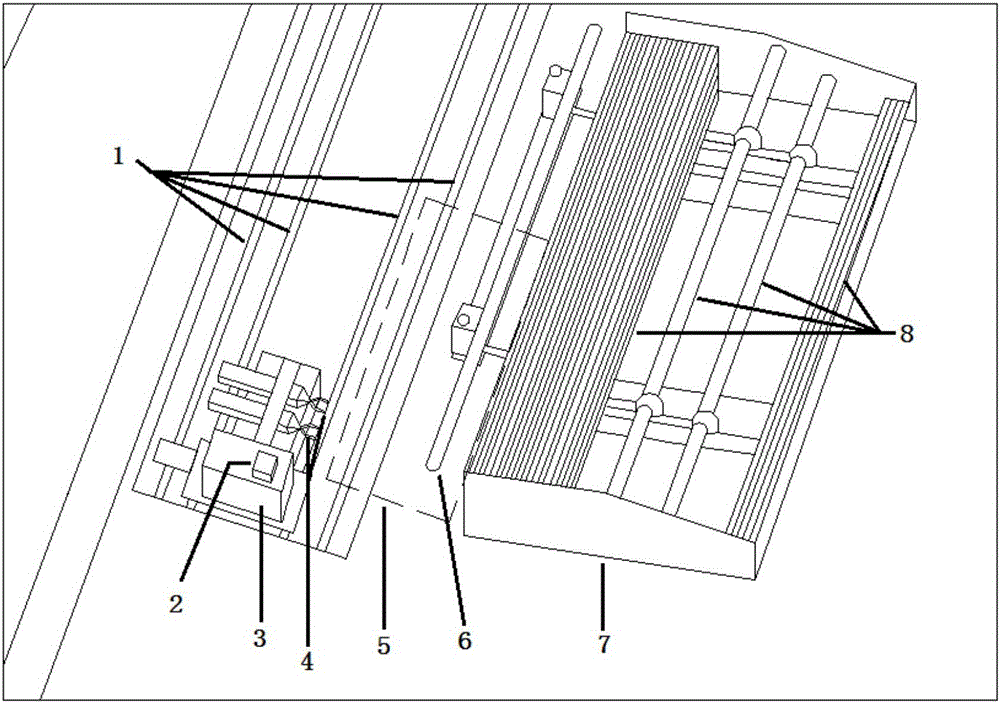

[0022] Step 1: Install the industrial camera and embedded processor. The image acquisition area of the industrial camera covers the area of the manipulator and the drill rod.

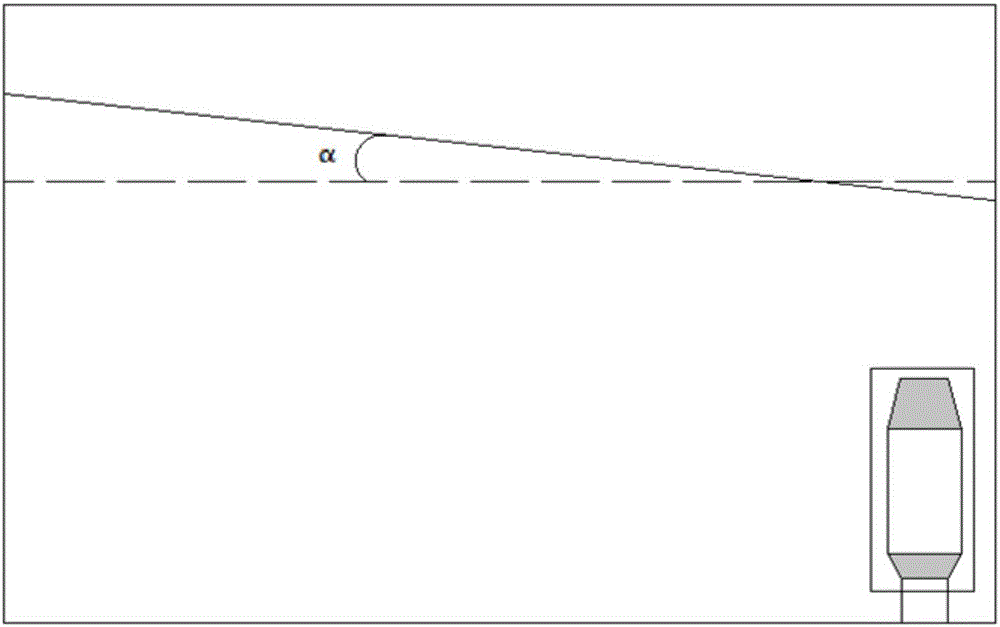

[0023] Step 2: Process the image collected by the industrial camera, and use Gaussian filtering, sharpening, edge detection, line detection and other steps to separate and detect the position of the drill rod 8 from the background.

[0024] Gaussian filter: It is a linear smoothing filter, suitable for eliminating Gaussian noise, and is widely used in the noise reduction process of image processing. In layman's terms, Gaussian filtering is a process of weighted average of the entire image, and the value of each pixel is obtained by weighted average of itself and other pixel values in the neighborhood. The specific operation of Gaussian filtering is: use a template (or convolution, mask) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com