A kind of compound enzyme preparation and its preparation method and application

A compound enzyme preparation and compound enzyme technology are applied in biochemical equipment and methods, wort preparation, enzymes and other directions, which can solve the problems of high wort turbidity and difficulty in filtering saccharified mash, and reduce the wort turbidity. , The preparation conditions are well controllable and the effect is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 2.5 parts by weight of medium temperature α-amylase with an enzyme activity of 250U, 4.5 parts by weight of high temperature resistant α-amylase with an enzyme activity of 1035U, 2.5 parts by weight of glucoamylase with an enzyme activity of 425U, 2.5 parts by weight of glucoamylase with an enzyme activity of 1750U Acid protease, 1 weight part of keratinase with 500 U enzyme activity, 5 weight parts of neutral protease with 2500 U enzyme activity, 7.5 weight parts of xylanase with 6000 U enzyme activity, 3 weight parts of cellulase with 10200 U enzyme activity , 3 parts by weight of beta-glucanase with enzyme activity of 1350U and 3 parts by weight of alpha-galactosidase with enzyme activity of 1350U as compound enzymes. The above compound enzyme is mixed with 65.5 parts by weight of cornstarch to obtain a compound enzyme preparation.

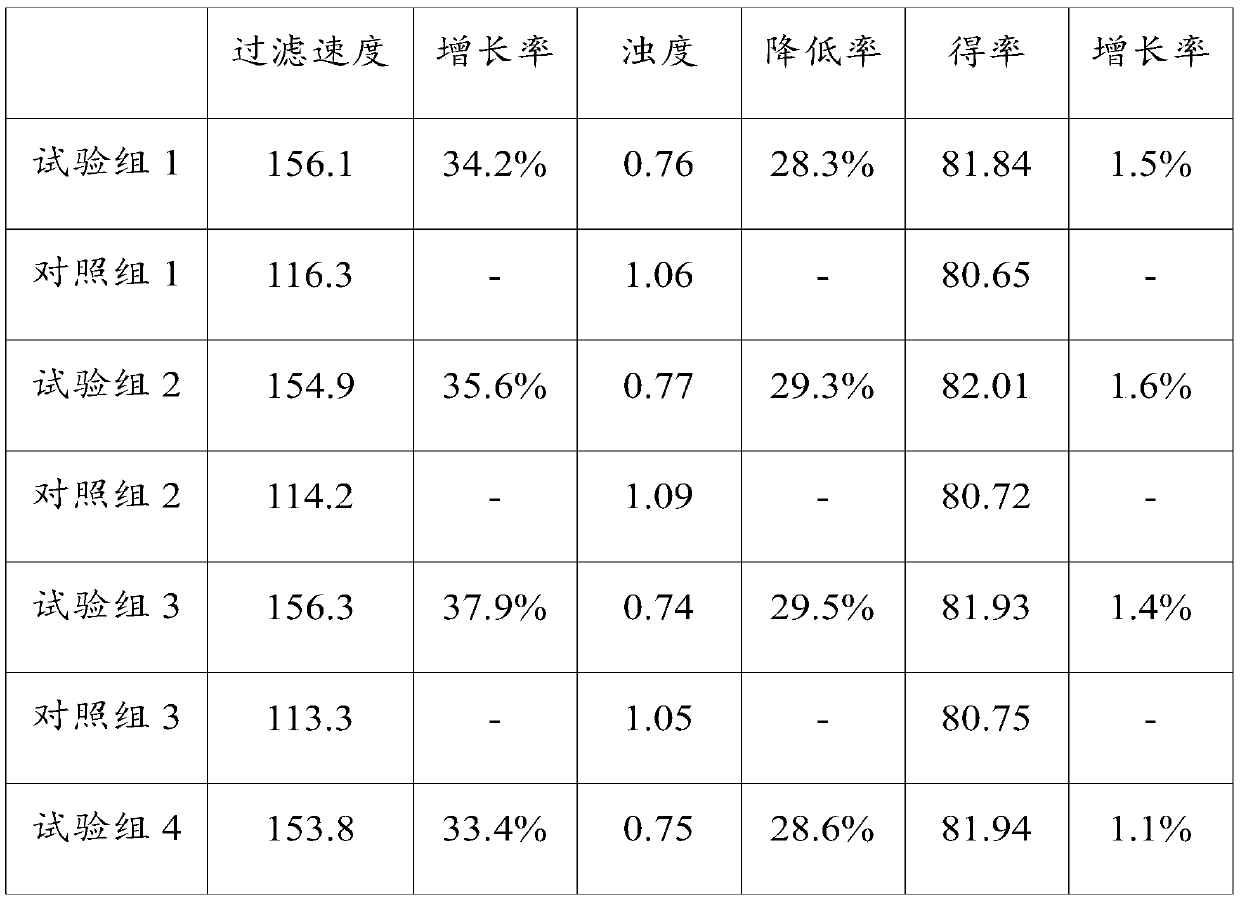

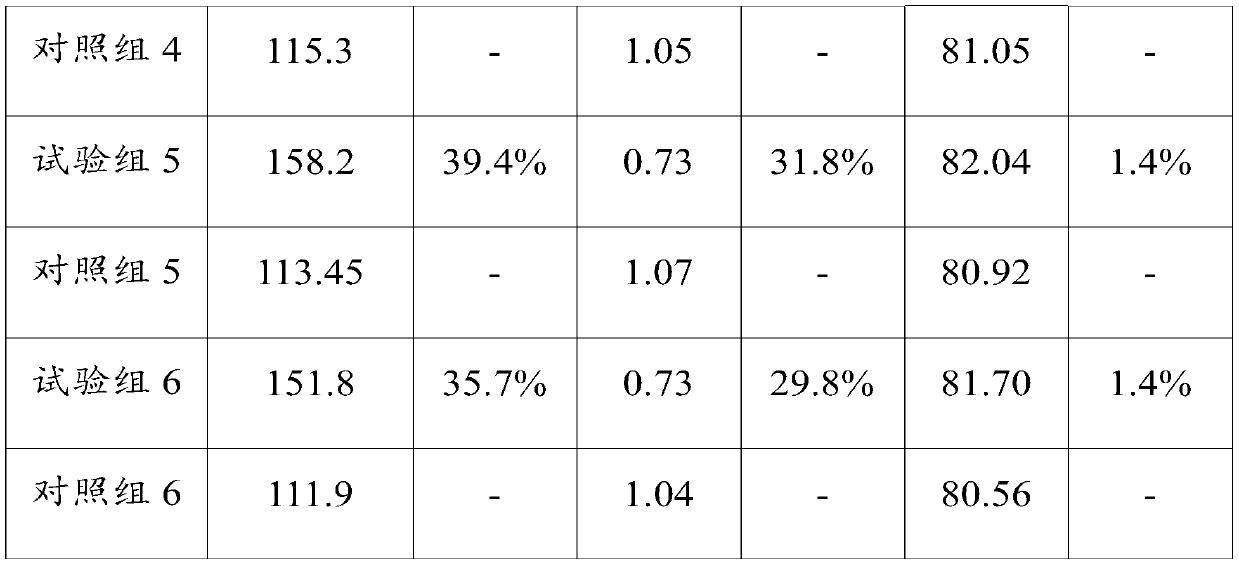

[0037] The malt is taken as the beer raw material, the above-mentioned compound enzyme preparation is added to the beer liquid to be sa...

Embodiment 2

[0039] 7.5 parts by weight of a medium-temperature α-amylase with an enzyme activity of 750U, 13.5 parts by weight of a high-temperature resistant α-amylase with an enzyme activity of 3105U, 7.5 parts by weight of a glucoamylase with an enzyme activity of 1275U, and 7.5 parts by weight of an enzyme with an activity of 5250U Acid protease, 5 parts by weight of keratinase with activity of 2500U, 15 parts by weight of neutral protease with activity of 7500U, 20 parts by weight of xylanase with activity of 16000U, 9 parts by weight of cellulase with activity of 30600U , 9 parts by weight of beta-glucanase with enzyme activity of 4050U and 6 parts by weight of alpha-galactosidase with enzyme activity of 2700U as complex enzymes. The above compound enzyme is mixed with 50 parts by weight of cornstarch to obtain a compound enzyme preparation.

[0040] Malt and rice are taken together as beer raw materials, and the above-mentioned compound enzyme preparation is added to the beer liquo...

Embodiment 3

[0042] 5 parts by weight of a medium-temperature α-amylase with an enzyme activity of 500U, 9 parts by weight of a high-temperature resistant α-amylase with an enzyme activity of 2070U, 5 parts by weight of a glucoamylase with an enzyme activity of 850U, and 5 parts by weight of an enzyme with an activity of 3500U Acid protease, 3 parts by weight of keratinase with activity of 1500U, 10 parts by weight of neutral protease with activity of 5000U, 13.75 parts by weight of xylanase with activity of 11000U, 6 parts by weight of cellulase with activity of 20400U , 6 parts by weight of β-glucanase with an enzyme activity of 2700U and 4.5 parts by weight of α-galactosidase with an enzyme activity of 2025U as compound enzymes. The above compound enzyme is mixed with 30 parts by weight of cornstarch to obtain a compound enzyme preparation.

[0043] Malt, rice and barley are taken together as beer raw materials, and the above-mentioned compound enzyme preparation is added to the beer li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com