A Biomass Pyrolysis Production Liquid Fuel Cogeneration Biochar System

A biomass pyrolysis and liquid fuel technology, which is applied in the direction of direct heating dry distillation, preparation of liquid hydrocarbon mixture, special form dry distillation, etc., can solve the problems of energy consumption and heavy maintenance workload of power consumption system, and achieve the reduction of bio-oil cost, saving pretreatment cost, and improving pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

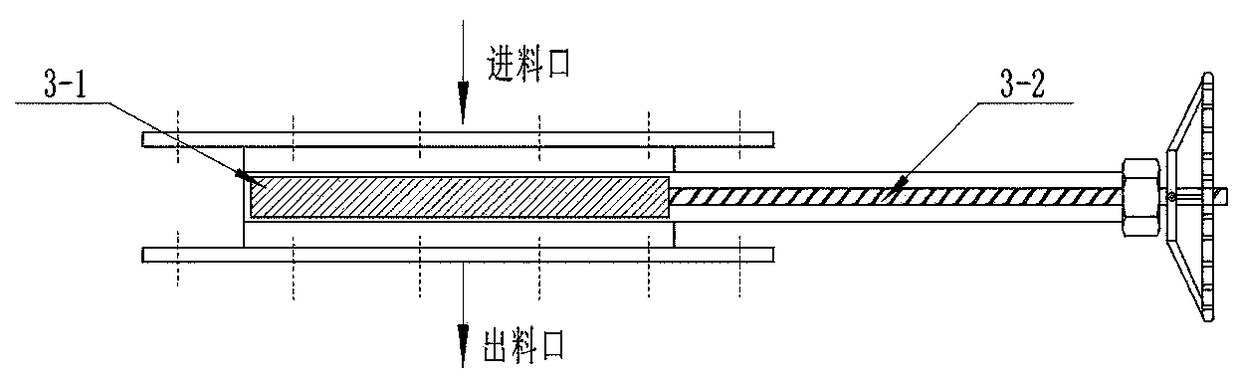

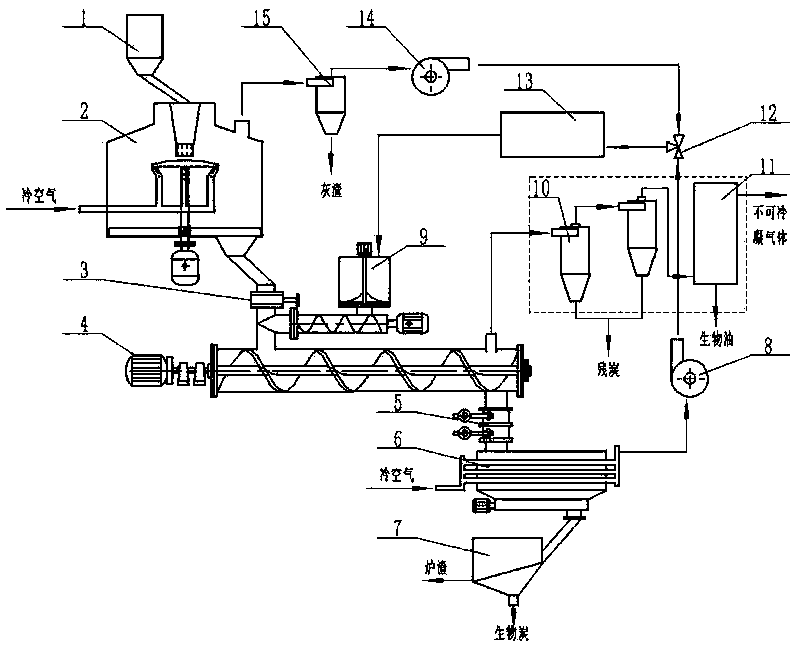

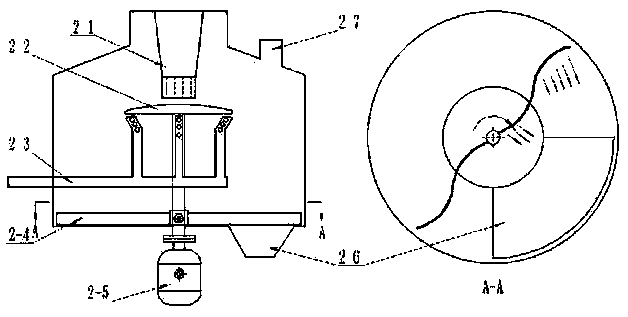

[0022] Such as figure 1 as shown,

[0023] A blast furnace slag biomass pyrolysis system, comprising a blast furnace 1, the blast furnace 1 is connected to a slag granulator 2, the slag granulator 2 is connected to a spiral reactor 4 through a pumping plate flow control valve 3, and the spiral reactor 4 is connected to a biomass feed The reactor 9 and the spiral reactor 4 are connected to the cyclone separator 10 and the bio-oil condenser 11 in sequence through the gas phase pipeline.

[0024] The biomass feeder 9 is connected to the fluidized bed dryer 13. After the hot air in the slag granulator 2 is separated by the gas-solid separator 15, the high-temperature flue gas induced draft fan 14 is sent to the fluidized bed dryer 13; the spiral reaction The solid phase outlet of the device 4 is connected to the ash unloading valve 5, the biochar and slag collection box 6 and the biochar / slag separator 7 through pipelines, and the biochar and slag are collected. The high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com