Compact type collection device and method for dissipated smoke dust of coke oven

A soot collection and compact technology, used in coke ovens, soot removal, discharge devices, etc., can solve the problems of long-term accumulation of environmental pollution, fugitive emissions, shutdown of gas blowers, etc., and achieve the effect of improving the efficiency of soot collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

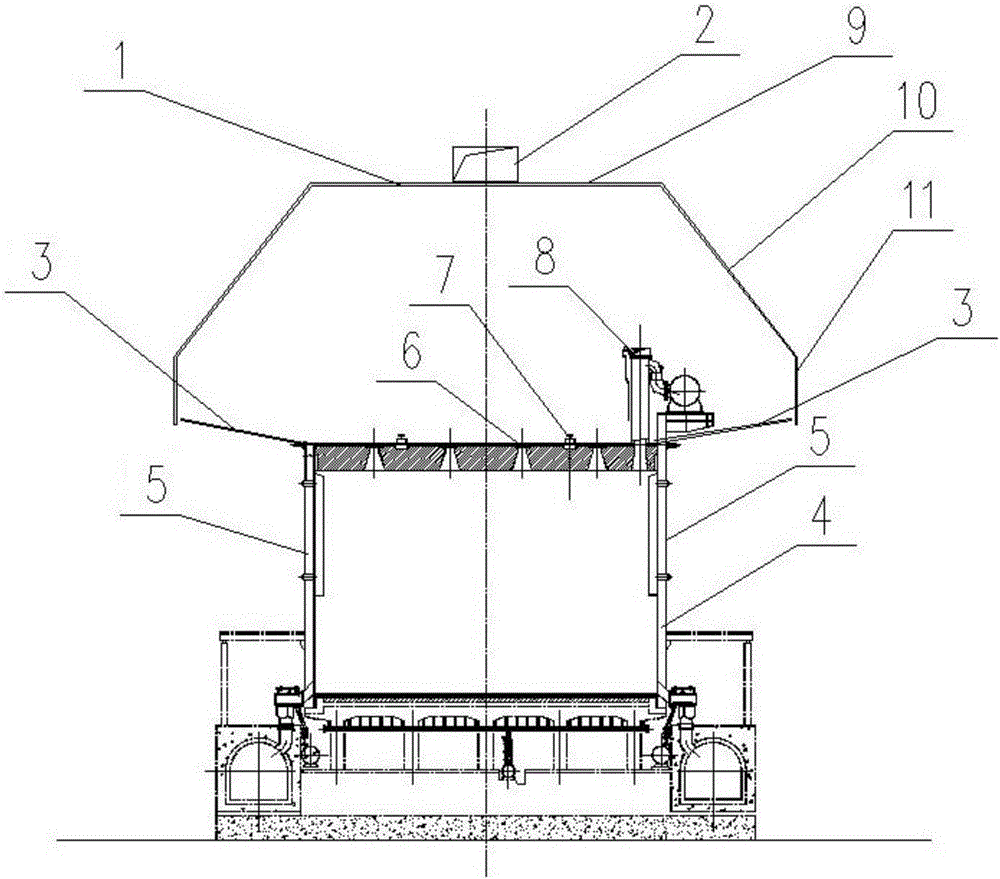

[0027] like figure 1 As shown, a compact coke oven fugitive dust collection device of the present invention includes a dust collection cover 1 and a windproof adjustment device 3; the dust collection cover 1 is arranged above the coke oven 4, and its projected area covers and Larger than the projected area of the coke oven 4, the center of the top of the dust collection hood 1 is provided with a flue gas conveying pipe 2 connected to the external dust purification treatment equipment; The annular space includes a windshield and an air volume adjustment mechanism. There are multiple air holes on the windshield, and the air volume adjustment mechanism is used to adjust the porosity of the windshield; the lower edge of the windshield is fixed on the coke oven 4 furnace Around the top, the height of the upper edge is higher than the height of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com