A kind of high temperature resistant and high efficiency foam discharge agent

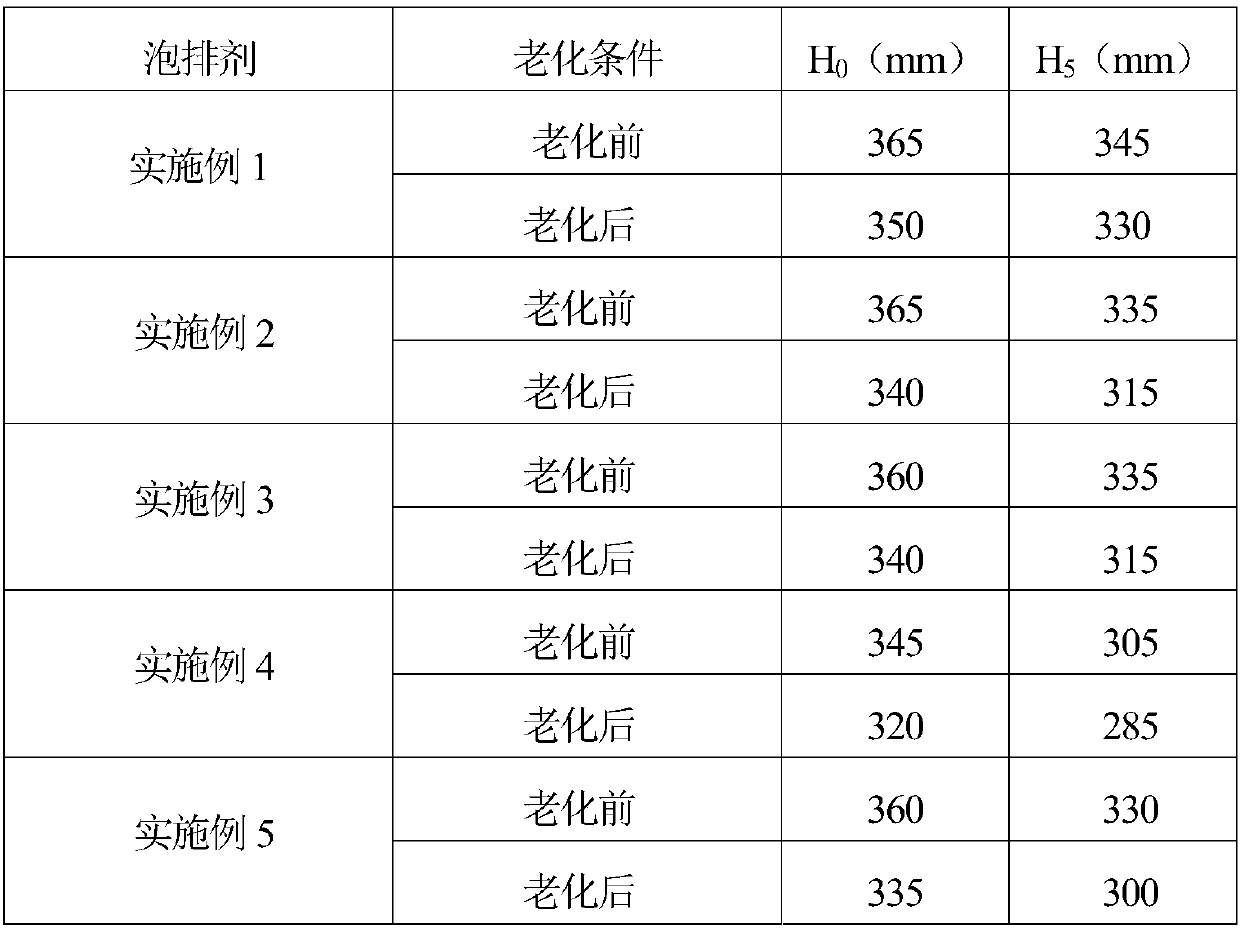

A technology of foam discharge agent and high temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve problems such as gas wells that cannot use pyridine corrosion inhibitors, compatibility of pyridine corrosion inhibitors, loss of foaming ability, etc. , to achieve excellent biodegradability, good salt resistance, and stable foam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

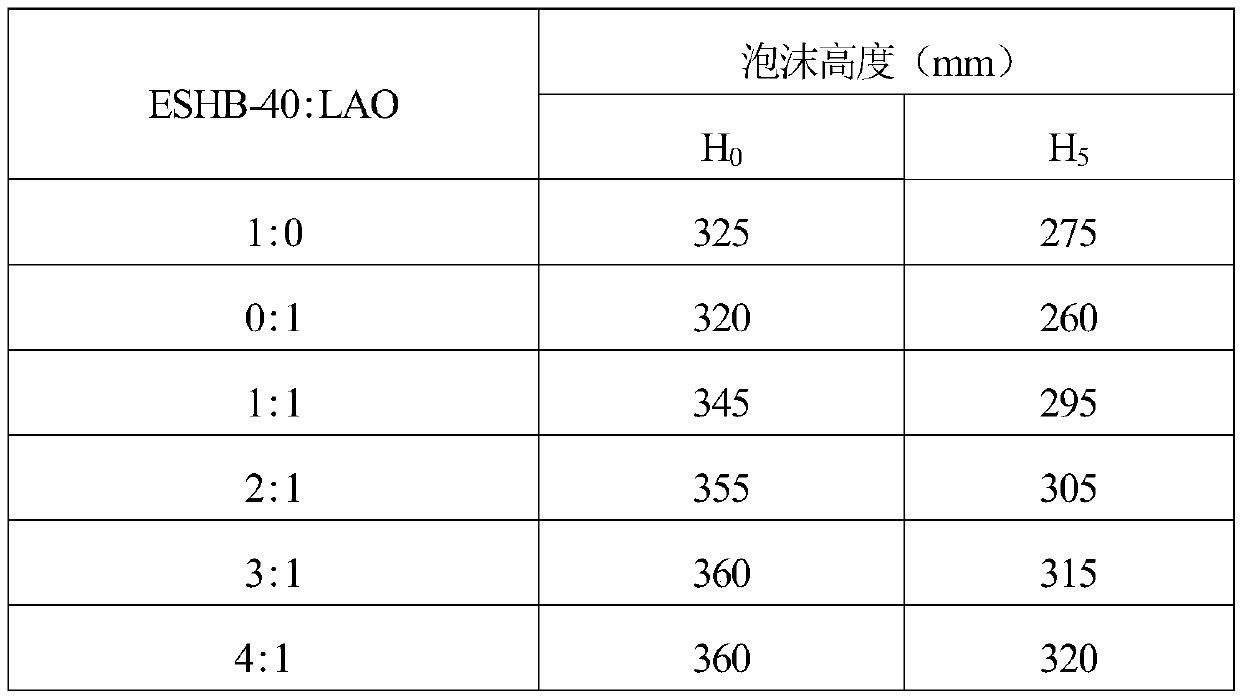

Method used

Image

Examples

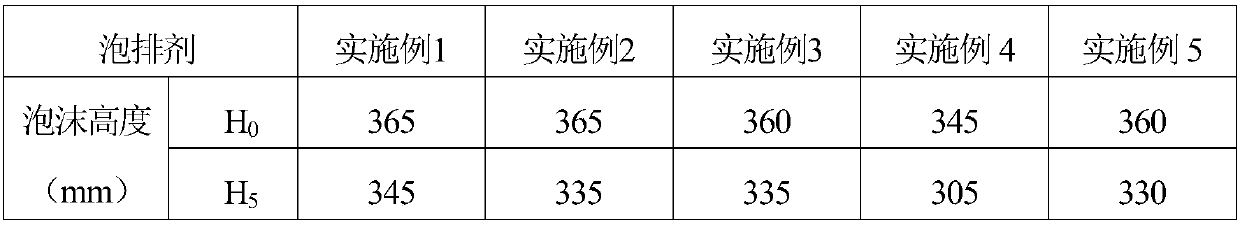

Embodiment 1

[0012] Mix 30 g of erucamide propyl hydroxysulfobetaine, 10 g of N-(dodecyl amidopropylene)-dimethyl ammonium oxide, and 6 g of xanthan gum evenly to obtain a foaming agent.

Embodiment 2

[0014] 30 g of erucamide propyl hydroxysultaine, 10 g of N-(dodecyl amidopropylene)-dimethyl ammonium oxide, and 4 g of xanthan gum were uniformly mixed to obtain a foaming agent.

Embodiment 3

[0016] Mix 30g of erucamidopropyl hydroxysulfobetaine, 10g of N-(dodecyl amidopropylene)-dimethyl ammonium oxide, and 8g of xanthan gum evenly to obtain a foaming agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com