Composite heating fast fermentation device of organic fertilizer

A fermentation device and compound technology, which is applied in the field of compound heating and rapid fermentation devices for organic fertilizers, can solve the problems of complex equipment structure, long fermentation time, and large floor area, and achieve accelerated fermentation process, high heating efficiency, and occupied area small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

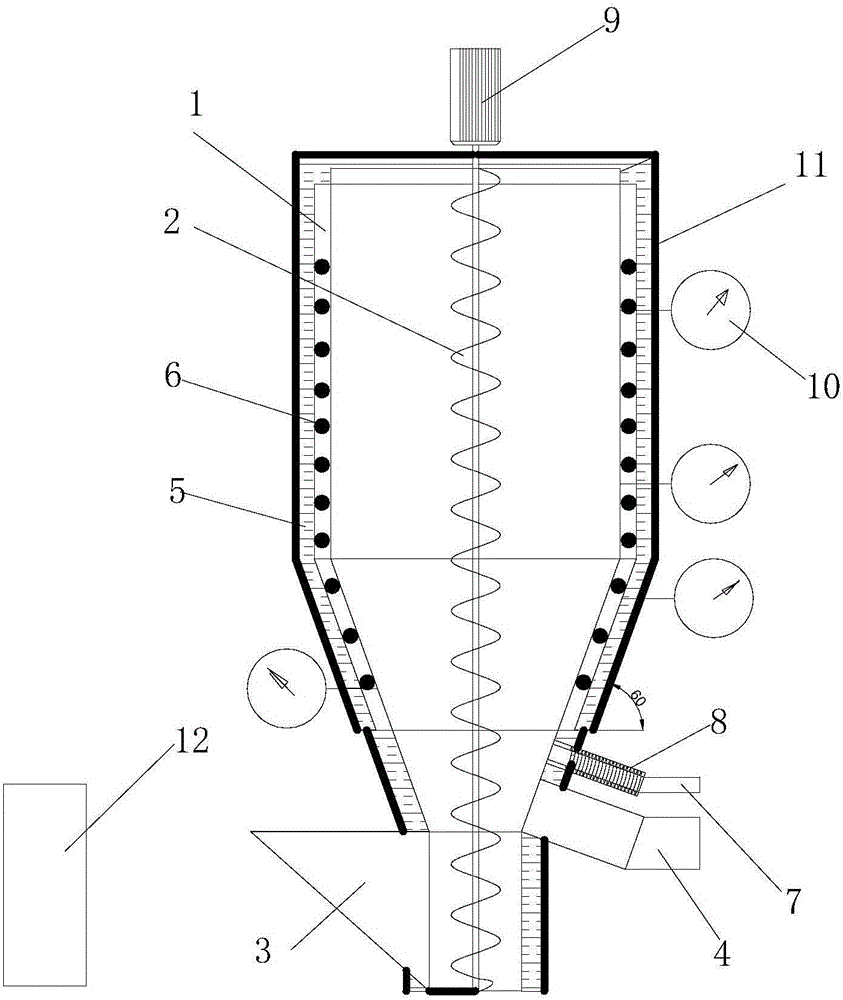

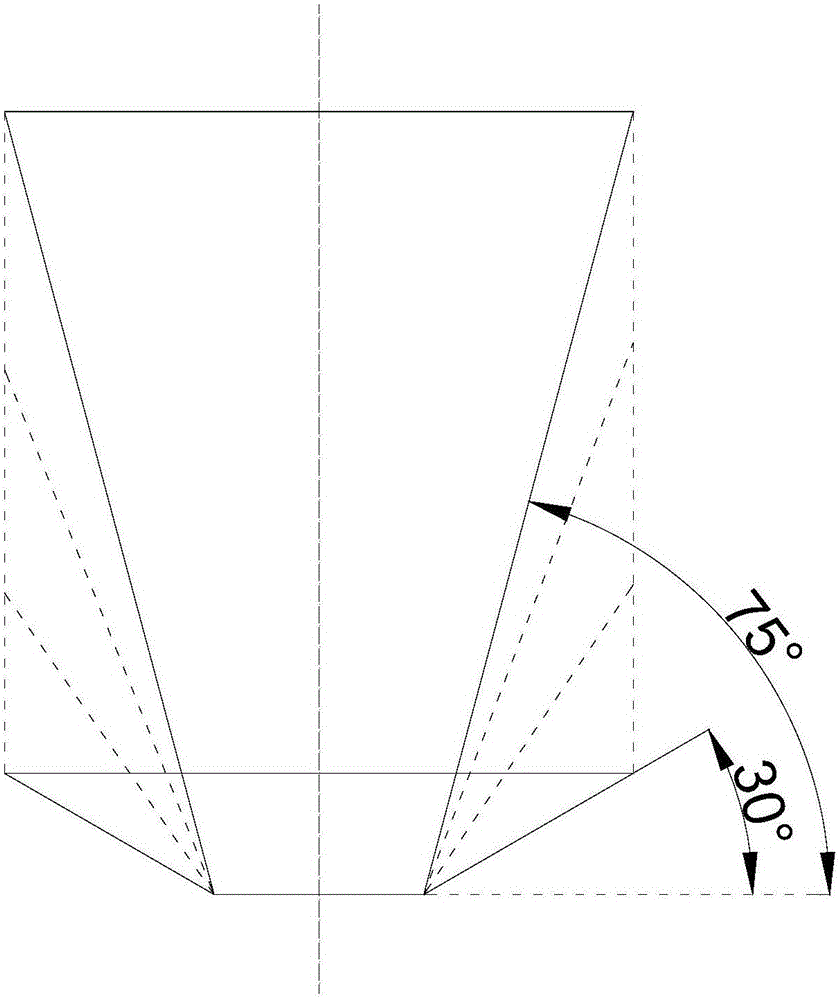

[0027] After the raw materials such as livestock and poultry manure and crop stalks are prepared according to a certain ratio by using normal temperature fermentation strains, the raw materials are fed from the lower end of the feed port, and the speed of the screw agitator is set to 120r / min. The raw materials are gradually lifted from the bottom of the cylinder from the center to the top, and then scattered in an umbrella shape, and then returned to the bottom, so that the raw materials are rolled and stirred up and down in the cylinder, and a large amount of raw materials can be evenly mixed in a short time. After the specified fermentation time is over, open the lower outlet, reversely rotate the stirring shaft, and export the fermented organic fertilizer.

Embodiment 2

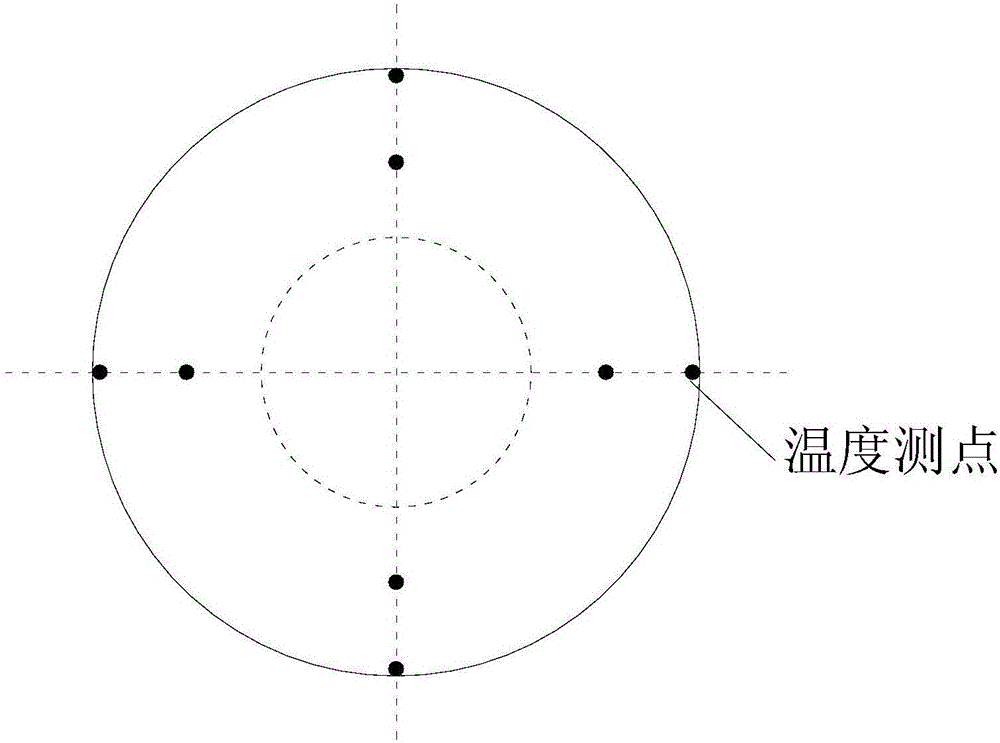

[0029] Select fermentation strains with a suitable temperature of 80-100°C, prepare livestock and poultry manure, crop straw and other raw materials according to a certain ratio, and feed them from the lower end of the feed port. After setting the speed of the screw agitator to 80r / min, use the motor Drive the rapid rotation of the spiral agitator to gradually lift the raw materials from the bottom of the cylinder from the center to the top, and then scatter them in an umbrella shape, and then return to the bottom, so that the raw materials are rolled up and down in the cylinder, and a large amount of raw materials can be evenly mixed in a short time. The mixing is complete. After the material is fed to the designated position, the hot air heating is turned on, and the air enters the heating air pipe to be heated and then sent into the cylinder; at the same time, the jacket heater is turned on. According to the measurement results of the temperature probes distributed outside ...

Embodiment 3

[0031]Select the fermentation strain whose fermentation temperature needs to be controlled at about 85°C. After preparing raw materials such as livestock and poultry manure and crop stalks according to a certain ratio, feed the material from the lower end of the feed port. After setting the speed of the screw agitator at 10r / min, use The motor drives the fast rotation of the spiral agitator to gradually lift the raw materials from the bottom of the cylinder from the center to the top, and then scatter them in an umbrella shape, and then return to the bottom. The mixing is complete. After the material is fed to the designated position, the hot air heating is turned on, and the air enters the heating air pipe to be heated and then sent into the cylinder; at the same time, the jacket heater is turned on. According to the measurement results of the temperature probes distributed outside the cylinder, the electric control box controls the temperature inside the cylinder to 85°C. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com