Fluidized bed hydrogenation reaction and separation process and device for producing hydrogen peroxide by virtue of anthraquinone method

A technology of fluidized bed reactor and hydrogenation reaction, which is applied in the fields of semipermeable membrane separation, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc. The utilization rate is low, the catalyst cannot be replaced at any time, and the quality of the hydrogen peroxide product is affected, so as to achieve the effect of simple structure, easy production, and small capital occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Hydrogenation reaction

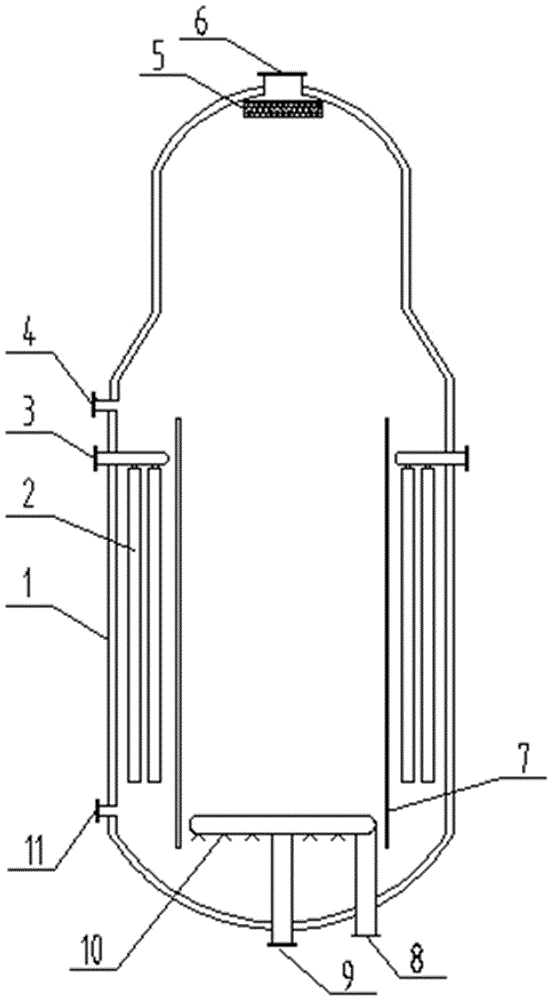

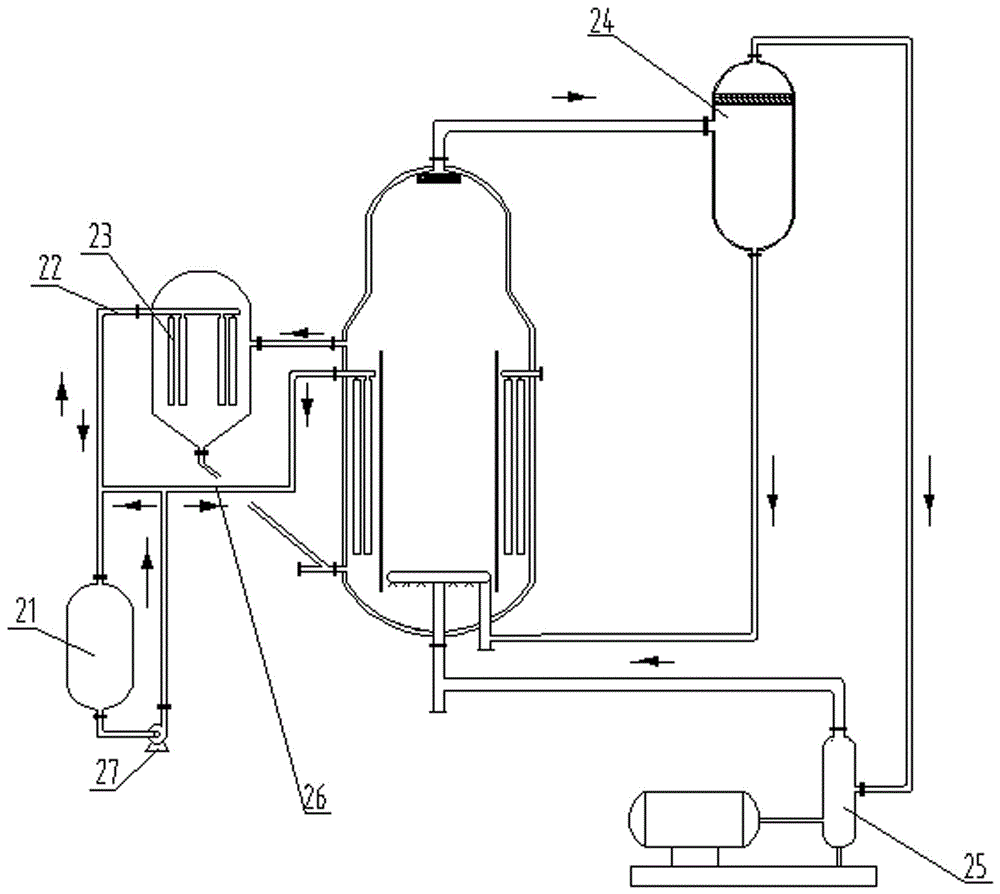

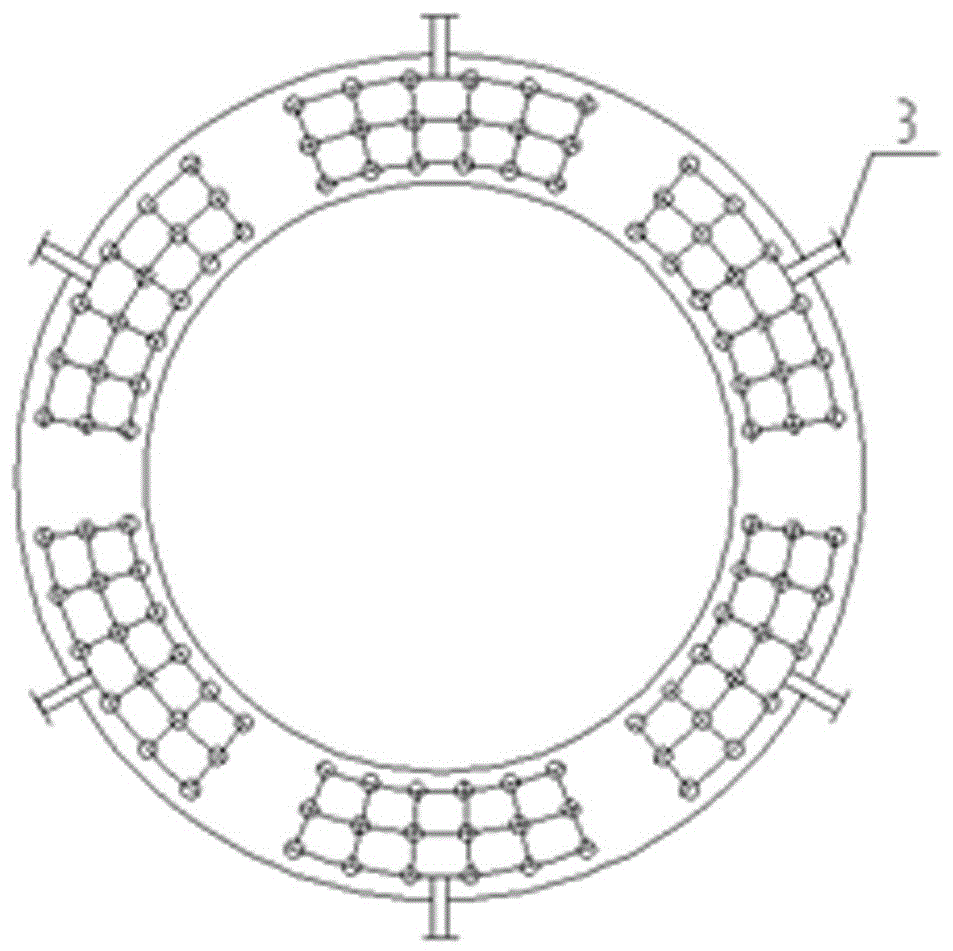

[0035] Into the fluidized bed hydrogenation reactor 1, the working fluid prepared with 2-ethylanthraquinone EAQ, heavy aromatics AR (C9 / C10) and tetrabutylurea TBU passes through the working fluid inlet 10 at a flow rate of 15m3 / h Continuously added, hydrogen with a purity of 99.99% is continuously added through the hydrogen inlet 9 at a flow rate of 110Nm3 / h. In the reactor, the hydrogen and working fluid are mixed by the gas-liquid distributor 10 and then move upward along the guide tube 7. The palladium catalyst The catalyst is added through the catalyst feeding port 11, the concentration of the catalyst is controlled to be 3.5-4.5%, the temperature in the fluidized bed hydrogenation reactor 1 is controlled to be 38°C-60°C, the pressure is 0.1-0.4MPa, and the hydrogen and working fluid are in the upward direction Contact with the catalyst during the moving process, hydrogenation reaction occurs under the action of the catalyst to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com