A tensioning mechanism for film-attached winding tube core

A technology of tensioning mechanism and film sticking, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., and can solve problems such as unfavorable processing efficiency and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

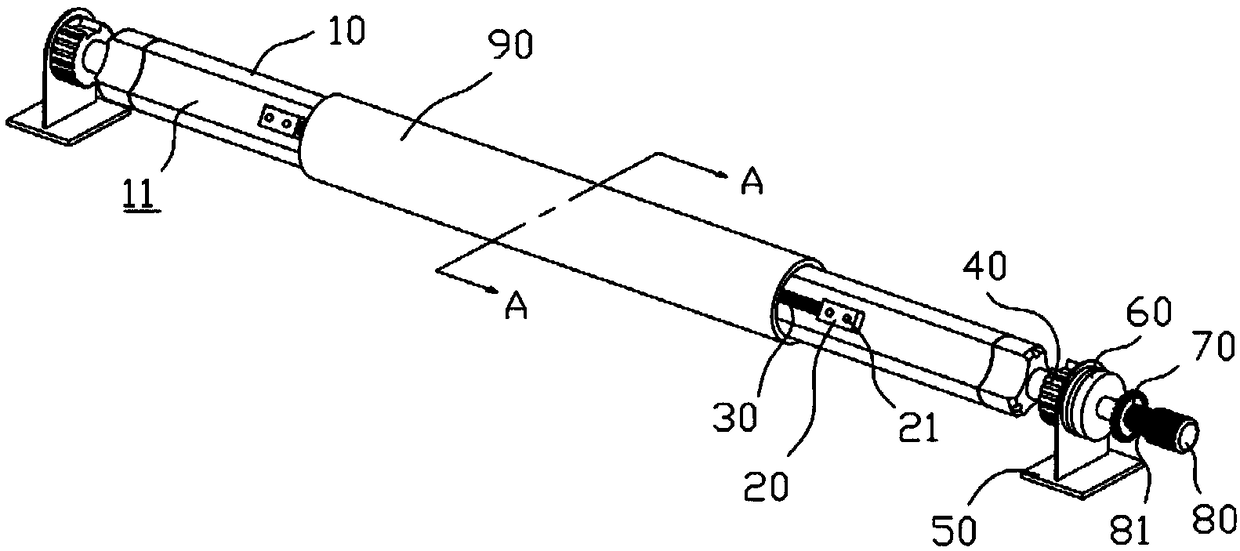

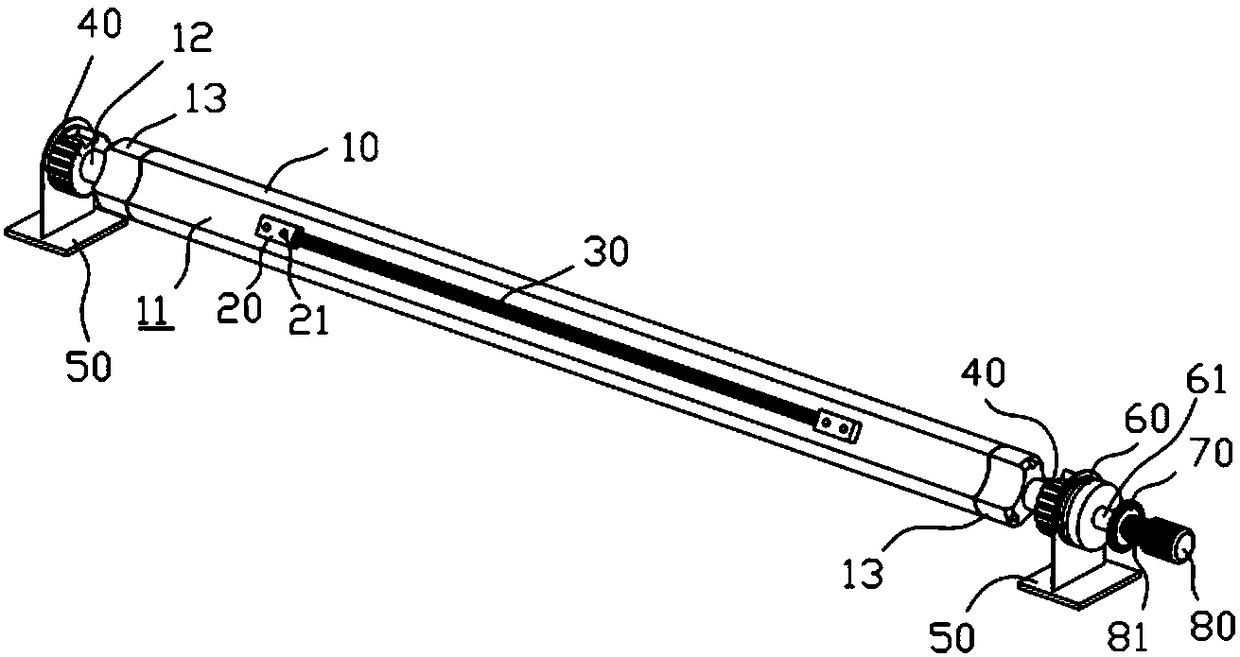

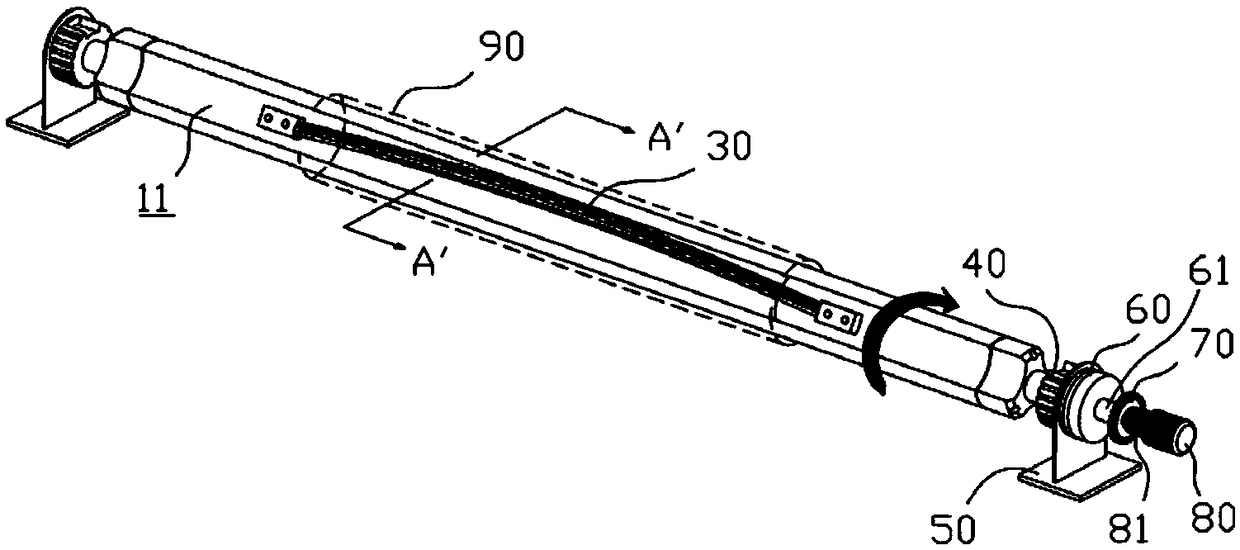

[0018] Such as Figure 2 to Figure 4 As shown, a tensioning mechanism for film-attached winding tube cores includes a main shaft 10, two locking blocks 13 are respectively provided at both ends of the main shaft 10, and the two locking blocks 13 are fixed to the main shaft 10 by several bolts. , the middle part of the main shaft 10 is the central shaft 12, the central shaft 12 is installed through the locking block 13, the central shaft 12 is fixed in the base 50 through the mounting block 40, and the base 50 is installed in the film processing machine tool On the frame; there are three big gaps 11 among the said main shaft 10, the big gaps 11 are arc-shaped, the three big gaps 11 are circumferentially arranged, and each big gap 11 is provided with two The fixing blocks 20 are provided with a tensioning strip 30 between the two fixing blocks 20 .

[0019] Such as Figure 4 As shown, the tension strip 30 is provided with a small gap 31 , and the outer diameter of the tension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com