Cotton lap pressure adjusting device

A technology of pressure regulation and lapping, which is applied in winding mechanism, textile and papermaking, fiber processing, etc. It can solve the problems of different compression force of the surface layer and troubles in the use of laps, and achieve the effect of maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

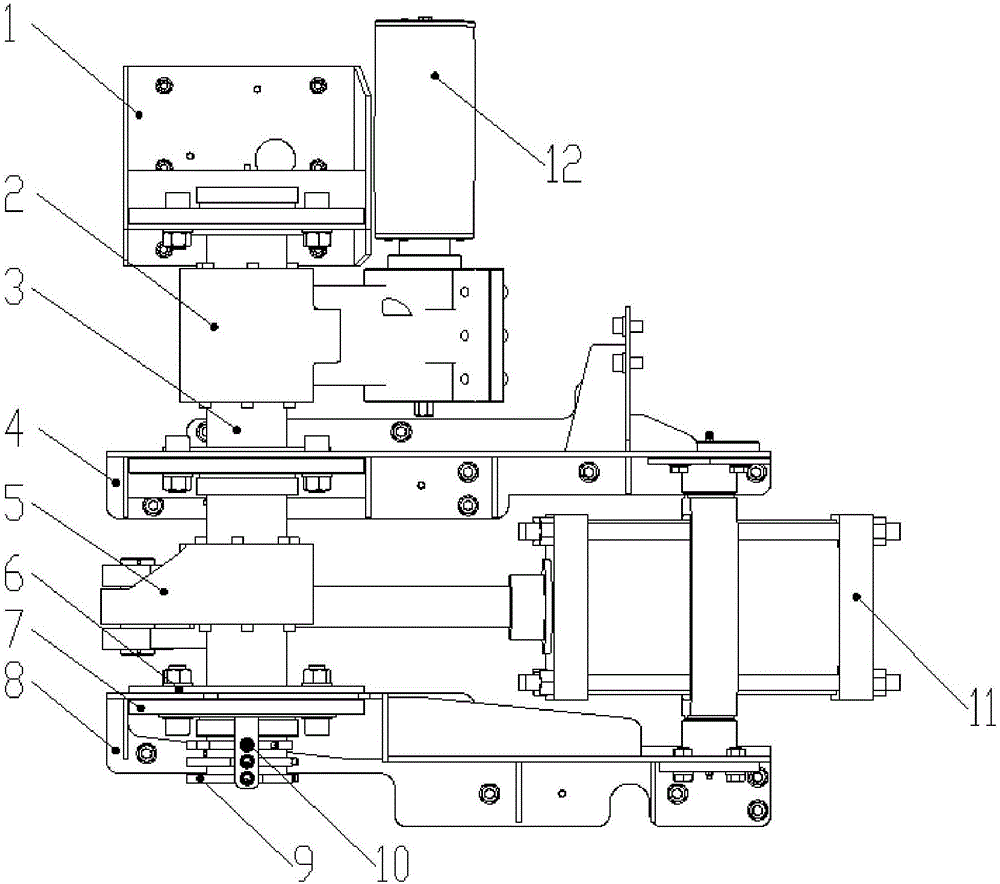

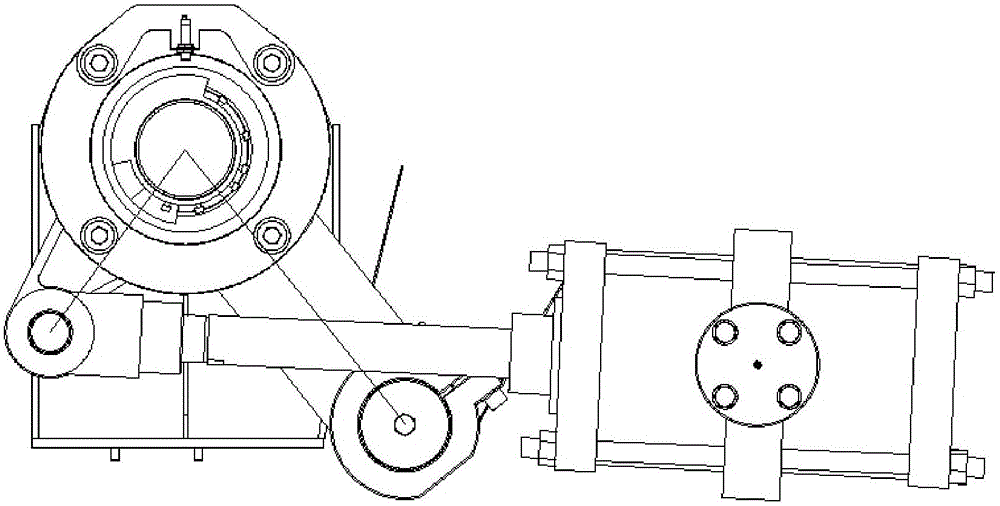

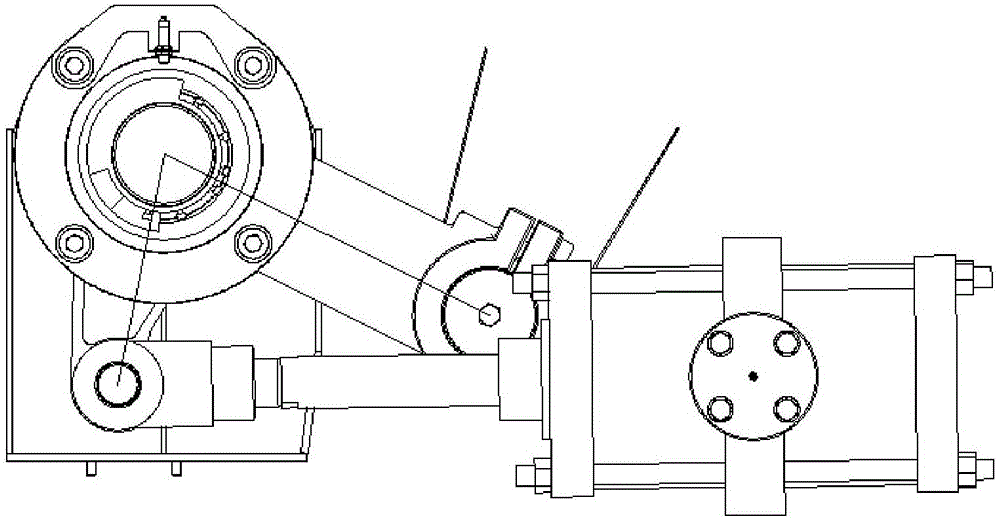

[0019] Embodiment: A lap pressure regulating device, comprising a bracket, an adjusting shaft 3, an adjusting connecting rod 2, a tension roller 12, a rotating drive mechanism and a control system, the adjusting shaft 3 is rotatably mounted on the bracket, and the adjusting connecting rod 2 One end of the rod 2 is fixedly installed on the adjusting shaft 3, and the tensioning roller 12 is fixedly installed on the other end of the adjusting connecting rod 2. The tensioning roller 12 is axially parallel to the adjusting shaft 3, and the rotating drive mechanism drives the adjusting shaft 3 to rotate, and the control system Control the work of the rotary drive mechanism.

[0020] The control system controls the rotary drive mechanism to drive the adjustment shaft 3 to rotate as required, so that the tension roller 12 can move up and down on a circular arc track, so as to realize the tension of the rolled belt, and then ensure that the belt increases with the diameter of the cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com