The Method of Preventing Axlebox Bearing from Abrasion by Adjusting the Joint Parameters of the Rotary Arm and the Joint of the Rotary Arm

A technology of axle box bearings and rotating arms, which is applied in the field of locomotive parts manufacturing, and can solve problems such as axle bearing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

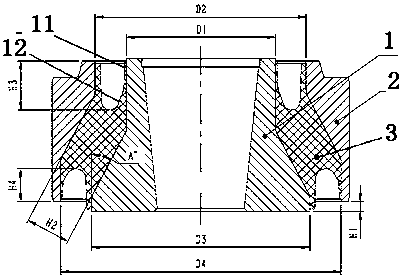

[0079] attached figure 1 and 2 A specific embodiment of the present invention is given; the joint of the rotating arm is formed by the combination of two elastic rubber parts with symmetrical structure, including the left metal outer sleeve 2 and the left metal inner sleeve 1, between the left metal outer sleeve 2 and the left metal inner sleeve 1 There is a left rubber layer 3 integrally vulcanized between the right metal outer sleeve 4 and the right metal inner sleeve 5, and a right rubber layer 6 is integrally vulcanized between the right metal outer sleeve 4 and the right metal inner sleeve 5; the left metal inner sleeve 1 and the right metal inner sleeve The inner holes of the inner sleeve 5 are tapered holes arranged opposite to each other, that is, the big head of the tapered hole is outside, and the small head of the tapered hole is close to each other on the inside; the characteristic is that the left rubber layer 3 and the right rubber layer 6 are opposite to each ot...

Embodiment 2

[0082] The structure of embodiment 2 is basically the same as that of embodiment 1, except that the parameters of the added rubber layer are different. The angle between the inclined surface of the rubber layer of the pivot arm node and the axis is 24~28 degrees; the length of the rubber layer is controlled at 38-45mm, left The thickness H of the rubber layer and the right rubber layer is 25-28mm; the inner diameter of the inner sleeve of the pivot arm node is set to 91~92mm, and the outer diameter is set to 129~130mm; the inner diameter of the outer sleeve is set to 129~130mm. The outer diameter is set at 171~172mm; the thickness of the rubber layer at the pivot arm node is controlled at 25-28mm.

Embodiment 3

[0084] Embodiment 3 has basically the same structure as Embodiment 1, except that the two ends of the rubber layer of the inner sleeve of the pivot arm node are dug inwards with a circle of annular grooves; wherein, the depth of the groove at the small diameter end H3 controls 15~30mm; the groove depth H4 at the end of the large diameter is controlled at 10~20mm. By digging a full circle of grooves, the radial stiffness of the boom node can be reduced, and the axial stiffness of the boom node can be improved, so that the boom The longitudinal stiffness of the nodes is controlled at 11-13KN.mm -1 , the axial stiffness is controlled at 6-8KN.mm -1 , so as to reduce the lateral load when the vehicle passes through the curve at high speed, reduce the wear of the bearing inside the axle box, and at the same time facilitate the installation without the need for empty phase.

[0085] The groove is a multi-section deep groove; wherein, the first section of the groove 11 is a single-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com