Mat production equipment with cutting device

A production equipment and cutting technology, applied in the direction of lamination devices, layered products, rubber layered products, etc., can solve problems such as large volume and affect production efficiency, and achieve overall volume reduction, which is conducive to full cooling and shaping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

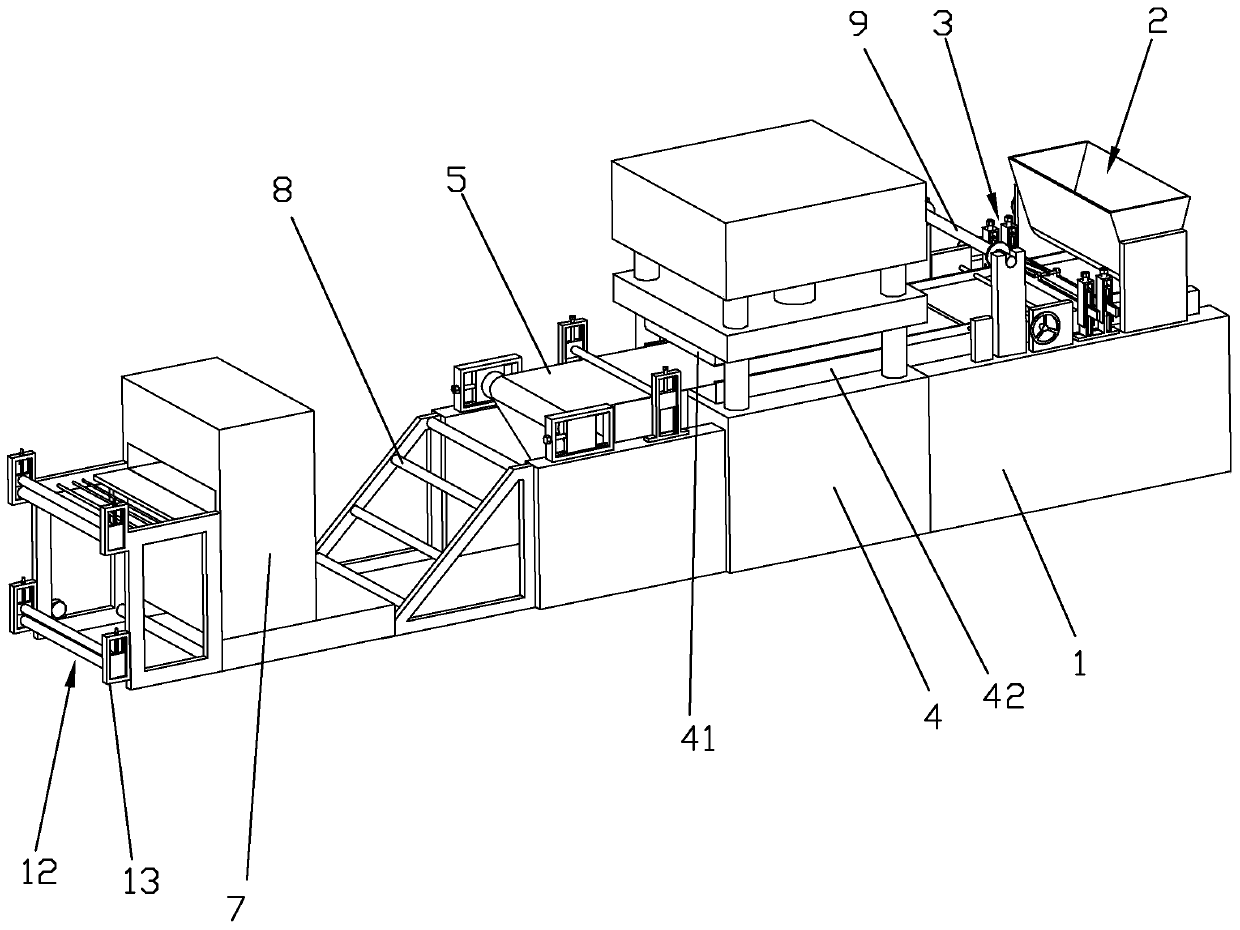

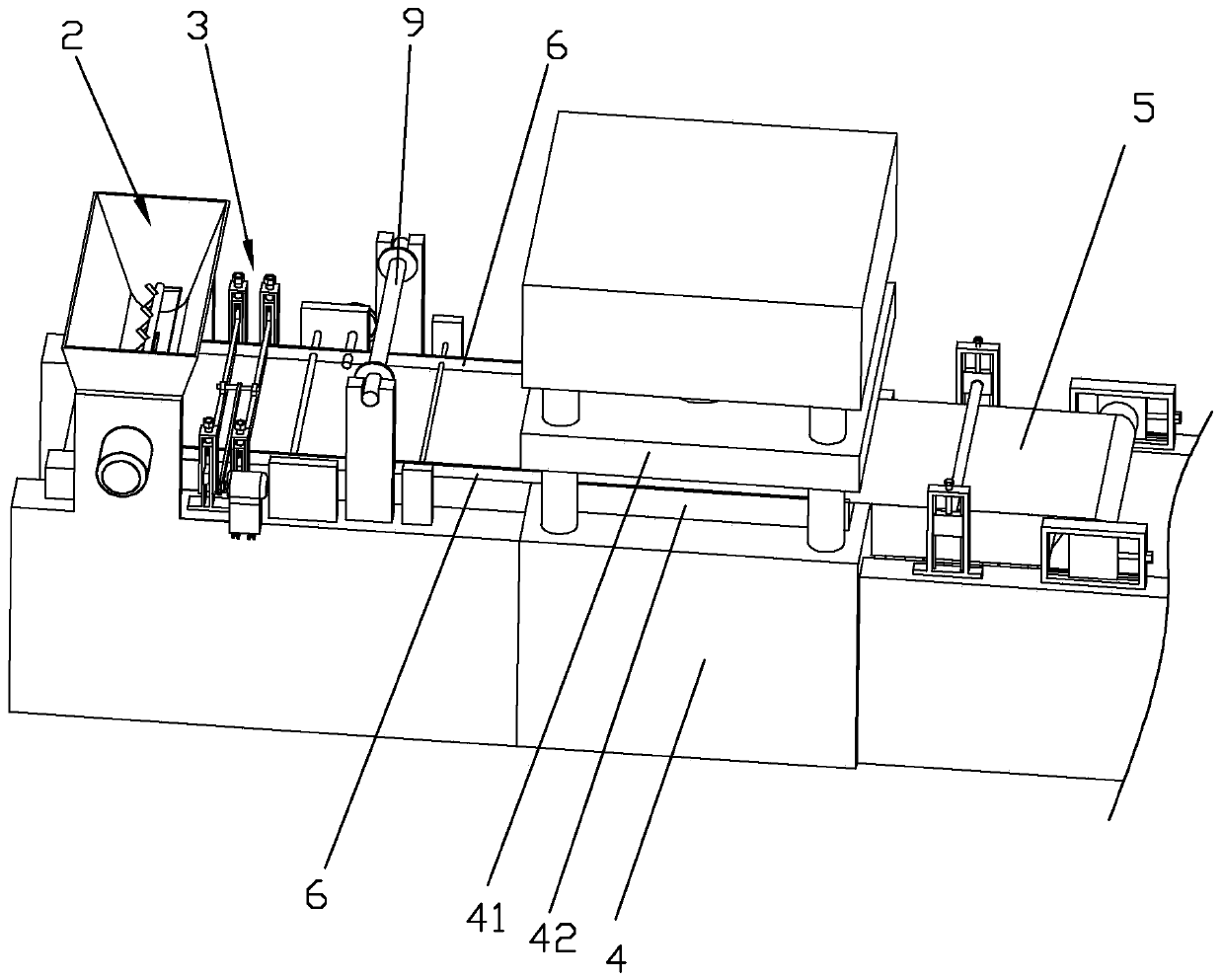

[0035] like figure 1 and figure 2 As shown, a cushion product production equipment with a cutting device includes a frame 1, a conveyor belt 5 is arranged on the frame 1, and a spreading device 2, a flattening device 3, and a cloth spreading device are arranged on the conveyor belt 5 along the conveying direction in sequence. Roller 9, hot press machine 4, multiple rotating rollers 8 arranged obliquely, cutting machine, driving roller 12. At the same time, baffles 6 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com