Built-in force sensor capable of directly measuring force

A force sensor and pressure sensor technology, applied in the field of force sensors, can solve the problem of low accuracy, achieve the effects of improving accuracy, avoiding structural instability and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

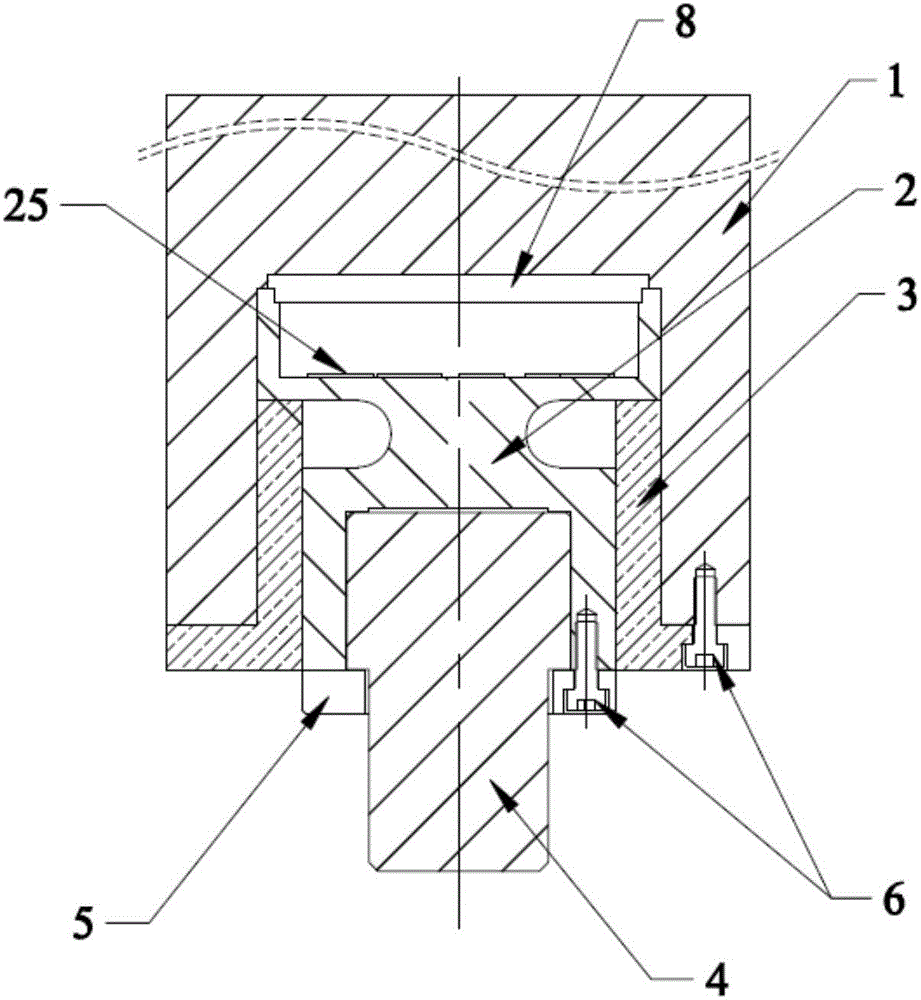

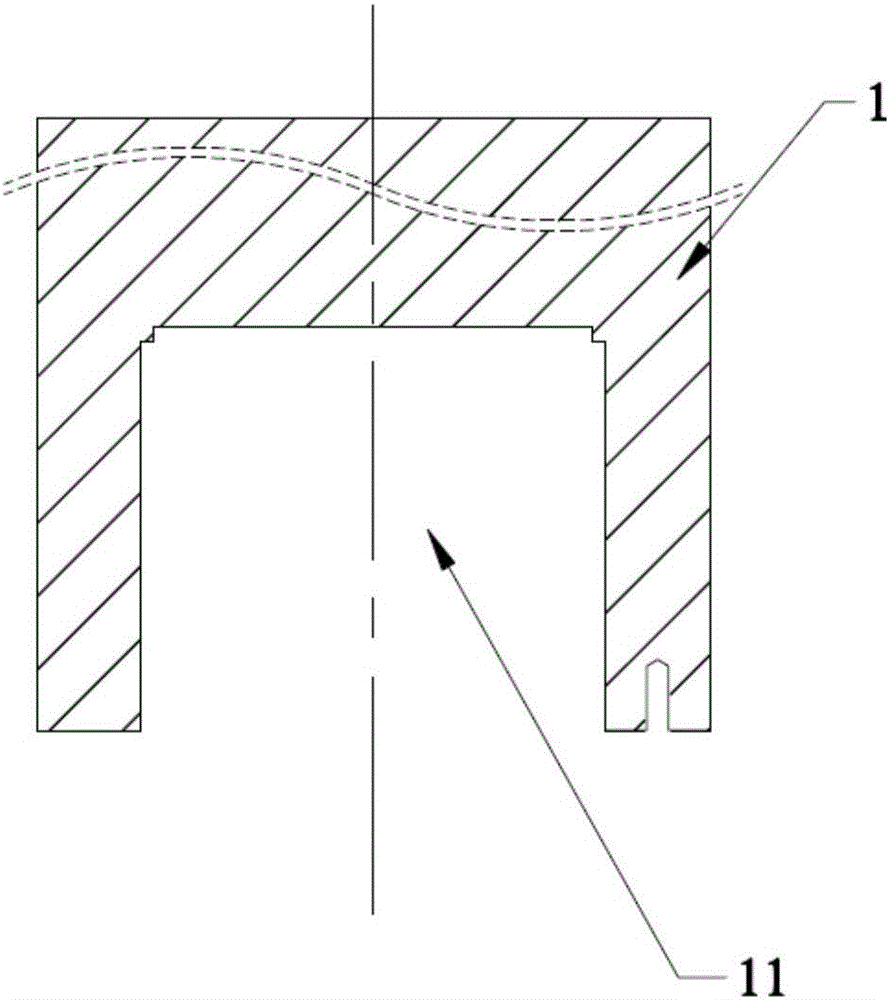

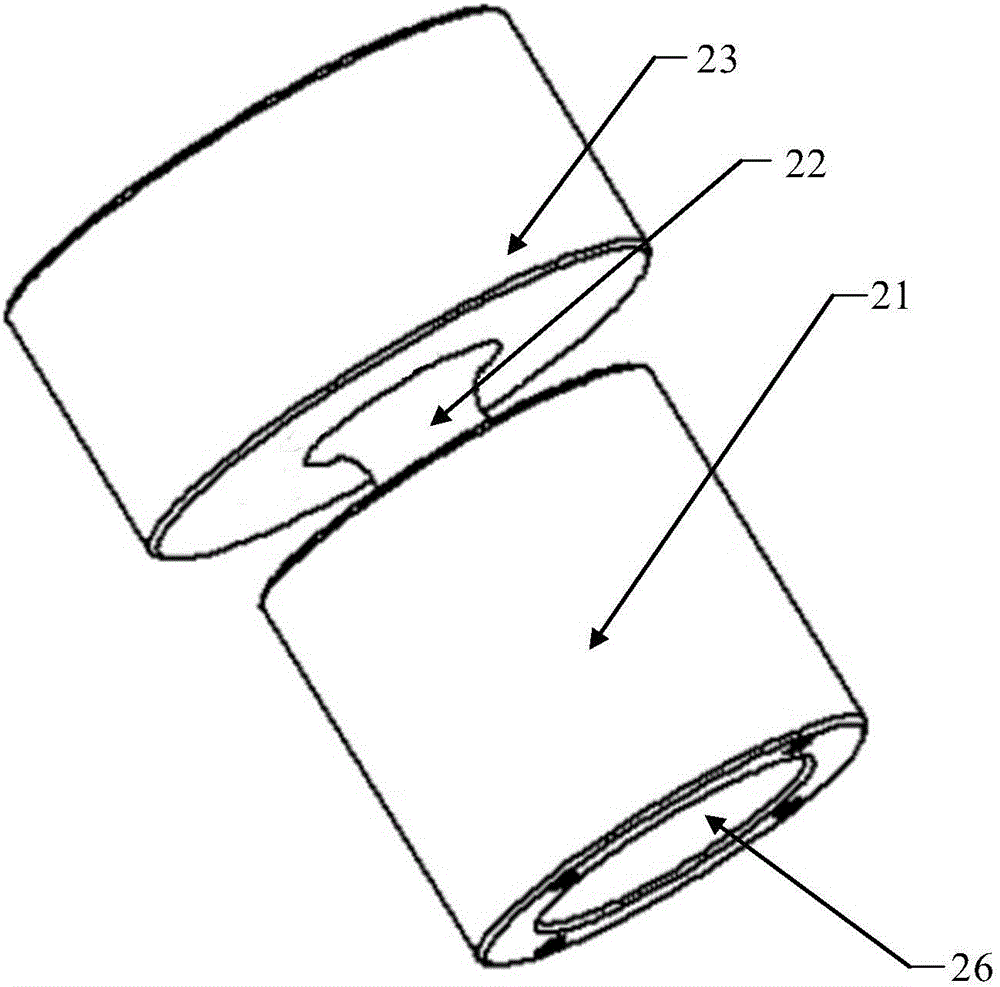

[0035] Such as figure 1 As shown, the present invention provides a built-in force sensor capable of directly measuring force, including a first pressure sleeve 1, a pressure sensor assembly 2, a second pressure sleeve 3, a pressure head 4, a flange 5 and an end cover 8 , the first pressure sleeve 1 is installed on the CNC press, such as figure 2 As shown, the free end of the first pressure sleeve 1 is provided with a first cylindrical inner hole 11, and the pressure sensor assembly 2 is installed inside the first cylindrical inner hole 11; as Figure 3-5 As shown, the pressure sensor assembly 2 includes a force-bearing end 21, a dowel 22 fixedly connected to the force-bearing end 21 at one end, and a force-measuring end 23 fixedly connected to the other end of the dowel 22. The free end surface of the force-measuring end 23 is connected to the The inner bottom surface of the first cylindrical inner hole 11 is in close contact, the free end of the force measuring end 23 is pr...

Embodiment 2

[0039] Such as Figure 8 As shown, the present invention provides a built-in force sensor capable of directly measuring force, including a first pressure sleeve 1, a pressure sensor assembly 2, a second pressure sleeve 3, a pressure head 4, a top wire 7 and an end cap 8, Compression sleeve 1 is installed on the CNC press, such as Figure 9 As shown, the free end of the first pressure sleeve 1 is provided with a first cylindrical inner hole 11, and the pressure sensor assembly 2 is installed inside the first cylindrical inner hole 11; as image 3 , 5 , 10, the pressure sensor assembly 2 includes a force end 21, a dowel 22 fixedly connected to the force end 21 at one end and a force measuring end 23 fixedly connected to the other end of the dowel 22, and the force measuring end 23 is free The end face is in close contact with the inner bottom surface of the first cylindrical inner hole 11, a second cylindrical inner hole 24 is provided at the free end of the force measuring en...

Embodiment 3

[0043] Such as Figure 12 As shown, the present invention provides a built-in force sensor capable of directly measuring force, including a first pressure sleeve 1, a pressure sensor assembly 2, a second pressure sleeve 3, a pressure head 4, a flange plate 5, and a top wire 7 And the end cover 8, the first pressure sleeve 1 is installed on the CNC press, such as Figure 9 As shown, the free end of the first pressure sleeve 1 is provided with a first cylindrical inner hole 11, and the pressure sensor assembly 2 is installed inside the first cylindrical inner hole 11; as Figures 13 to 15 As shown, the pressure sensor assembly 2 includes a force-bearing end 21, a dowel 22 fixedly connected to the force-bearing end 21 at one end, and a force-measuring end 23 fixedly connected to the other end of the dowel 22. The free end surface of the force-measuring end 23 is connected to the The inner bottom surface of the first cylindrical inner hole 11 is in close contact, and the free end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com