High-efficiency multi-functional twin-screw extruder

A twin-screw extrusion, multi-functional technology is applied in the field of high molecular polymer material processing equipment, which can solve the problems of high production cost and low efficiency, and achieve the effects of simple operation, improved quality, and favorable automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further explained below in conjunction with the accompanying drawings.

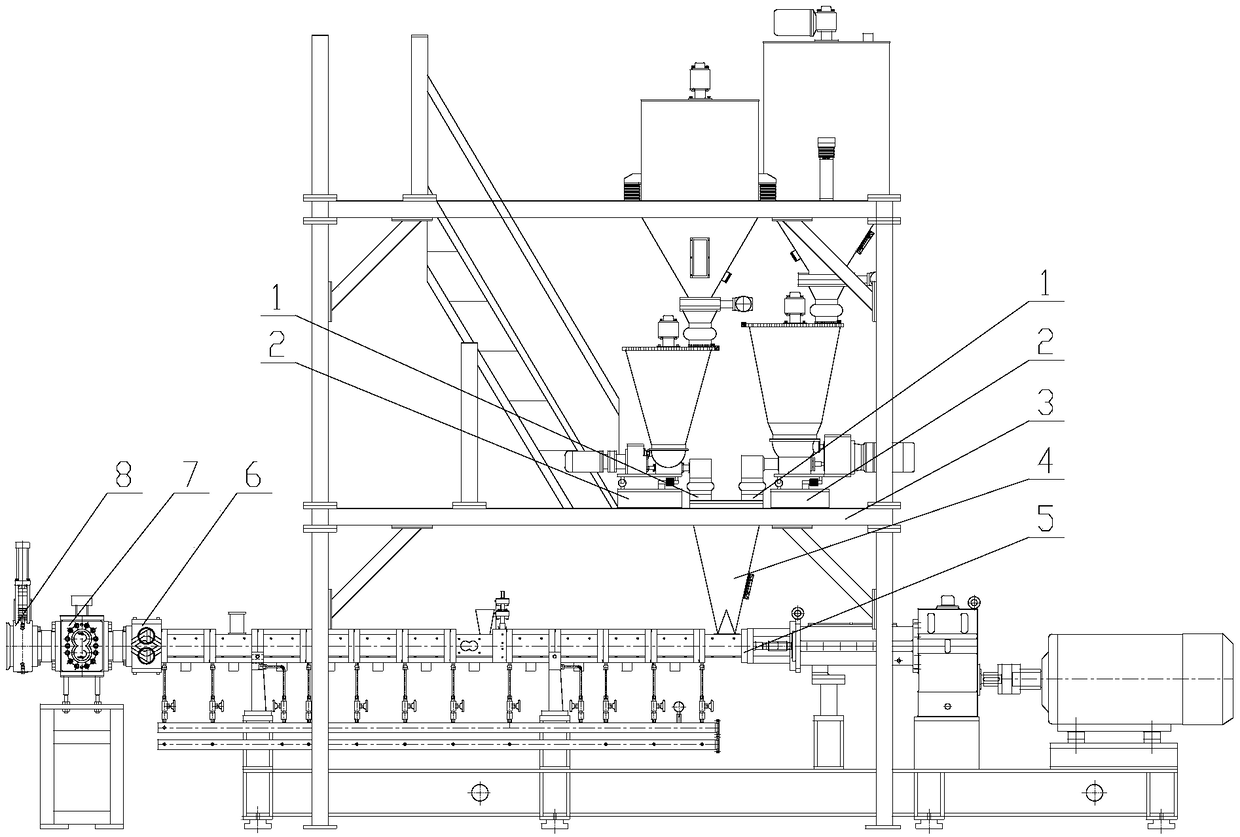

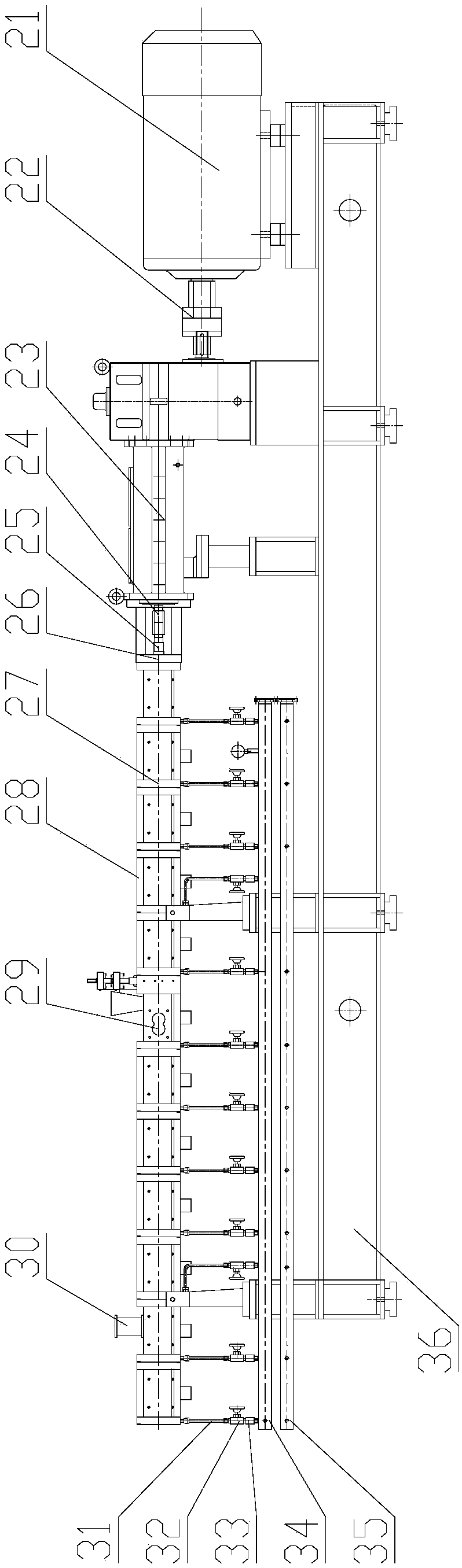

[0042] Such as figure 1 As shown, a high-efficiency multifunctional twin-screw extruder unit of the present invention includes a weightless continuous weighing metering feeding device 2, a steel frame platform 3, a co-rotating parallel twin-screw mixing extruder 5, a double-plunger hydraulic Screen changing device 6, high temperature melt pump 7 and hydraulic diverter valve 8.

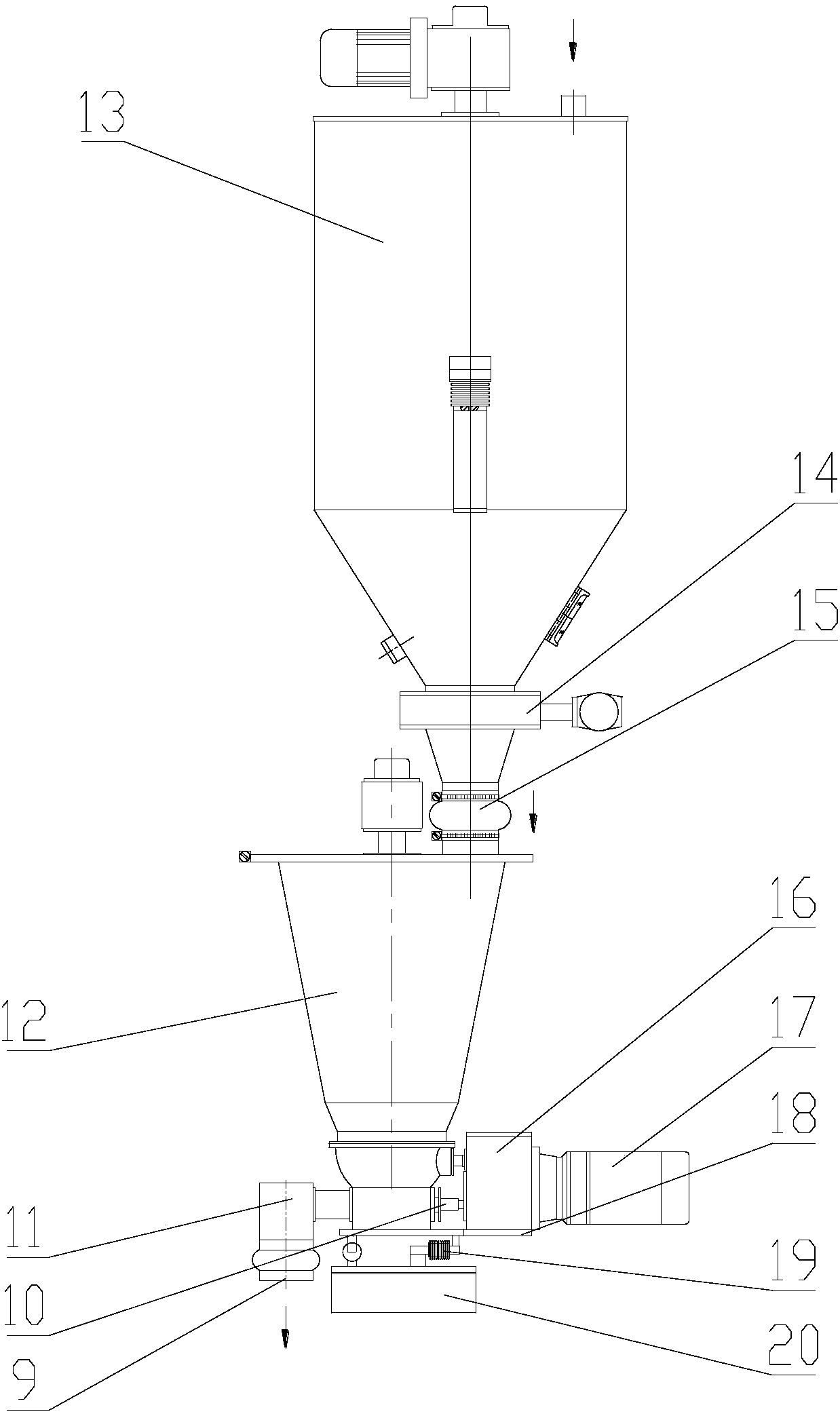

[0043] Such as figure 1 and 2 As shown, the high-efficiency multifunctional twin-screw extruder unit can be equipped with at least two loss-in-weight continuous weighing metering and feeding devices 2 according to the polymer components of the production operation. The loss-in-weight continuous weighing metering feeding device 2 is installed on the steel frame platform 3 . The loss-in-weight continuous weighing and metering feeding device 2 includes a raw material bin 13 for storing raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com