Rice germ cutting device

A cutting device and germ technology, applied in metal processing, etc., can solve problems such as the inability to guarantee the simultaneous impact of rice grains, the increase in the rate of rice grain breakage, and the breaking and breaking of rice grains, so as to achieve batch cutting and industrial production, retain nutritional value, The effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

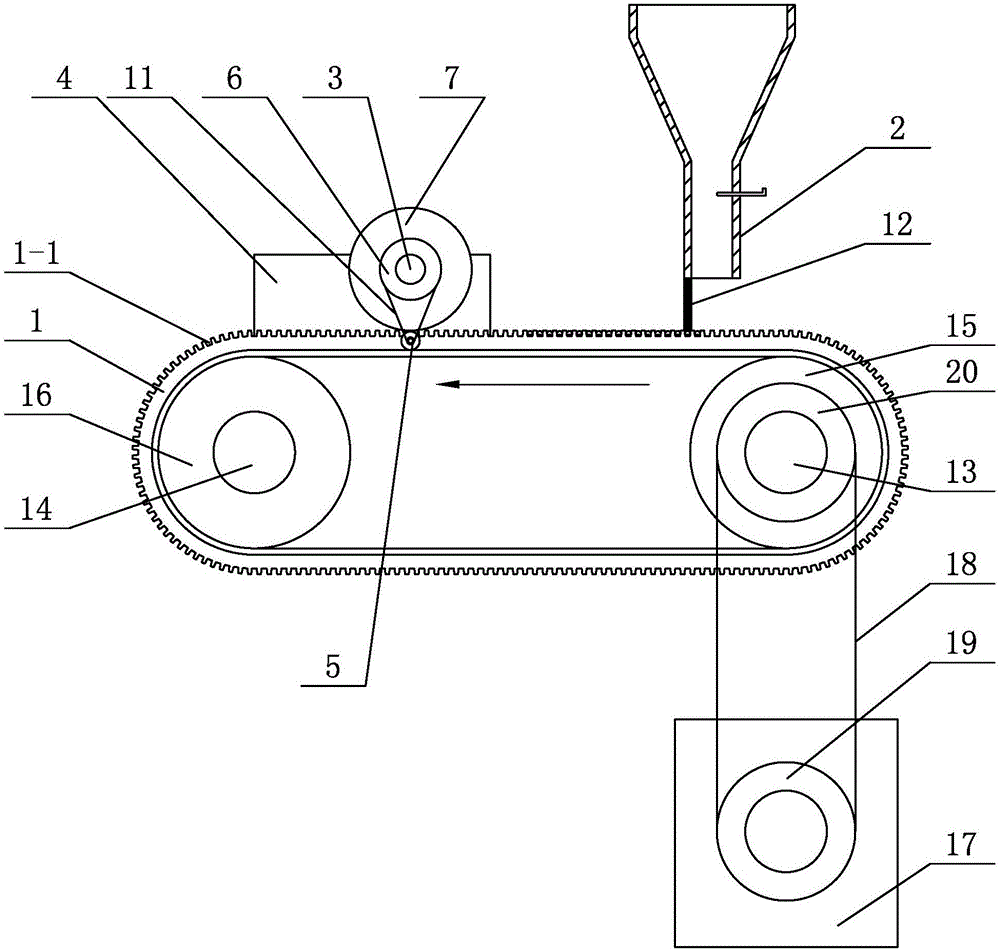

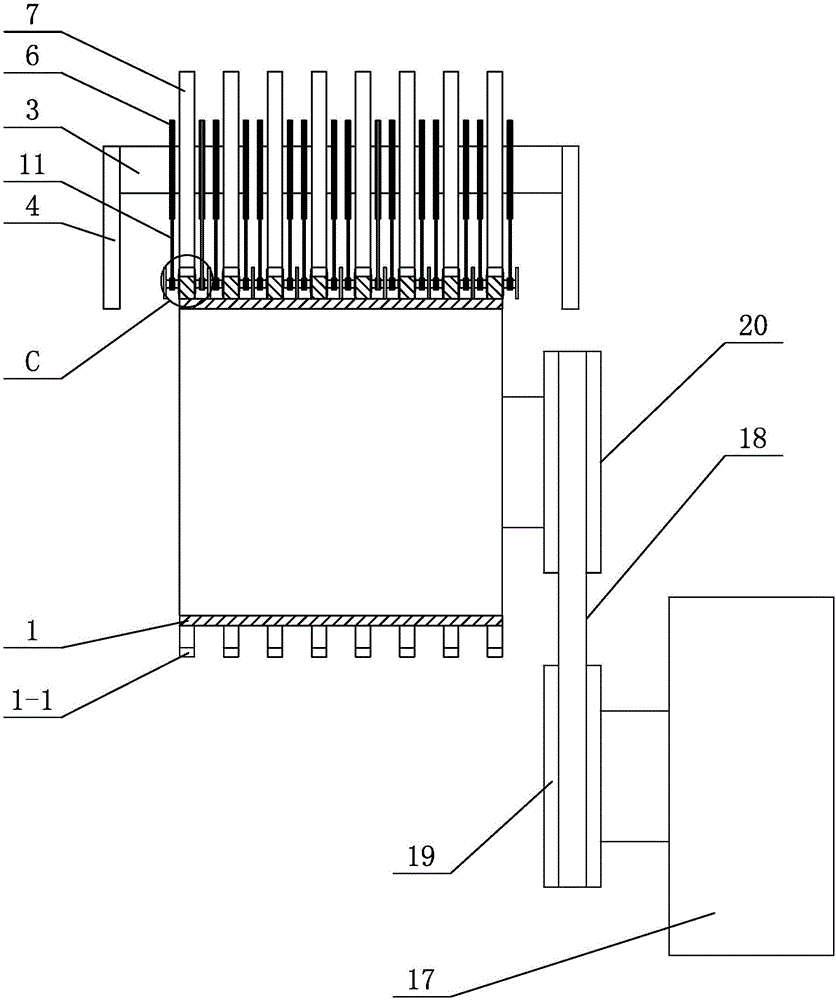

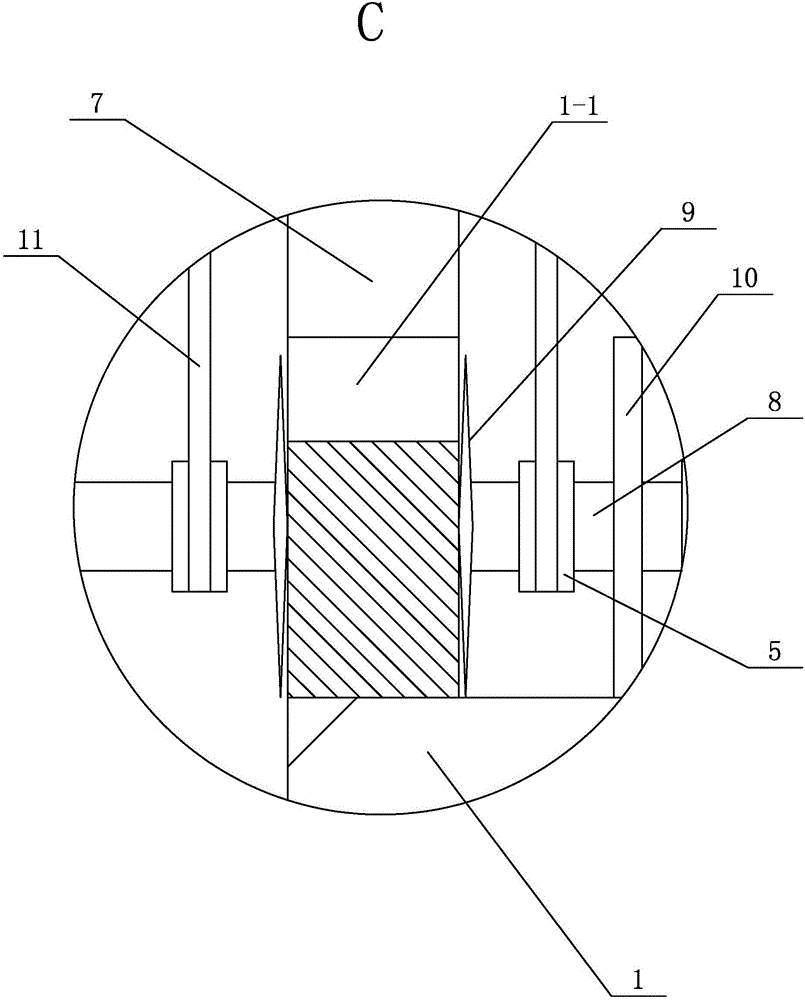

[0007] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a rice germ cutting device described in this embodiment includes a frame, a main drive mechanism, a conveyor belt 1, a hopper 2, a pressure roller shaft 3, two side plates 4, at least one small pulley 5, at least one Large pulley 6, at least one pressure roller 7, at least two saw blade shafts 8, at least two saw blades 9, at least two partitions 10 and at least one transmission belt 11, the main drive mechanism is installed on the frame Above, the conveyor belt 1 is installed on the main drive mechanism, the hopper 2 is arranged above the starting end of the conveyor belt 1, and the outer surface of the conveyor belt 1 is provided with at least one row of U-shaped grooves 1- 1. The length of each U-shaped groove 1-1 is less than the length of the rice grain, and the left and right sides along the advancing direction of the conveyor belt 1 are provided with partitions 10 and side p...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 1 to Figure 5 To illustrate this embodiment, the edge of each pressing roller 7 of the rice germ cutting device described in this embodiment is adjacent to but not in contact with the blade portion of the corresponding saw blade 9 . The preferred distance between the edge of each pressing roller 7 and the edge portion of the corresponding saw blade 9 is 0.1mm˜0.2mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 1 to Figure 5 To illustrate this embodiment, the lower end of the hopper 2 of a rice germ cutting device described in this embodiment is provided with at least one distributing channel 2-1 side by side, and each distributing channel 2-1 corresponds to a direction along the forward direction of the conveyor belt 1. A row of U-shaped grooves 1-1, the front side of the outlet at the lower end of each distribution channel 2-1 is provided with a brush 12, and the lower end of the brush 12 is in contact with the upper surface of the U-shaped groove 1-1 on the conveyor belt 1 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com