Safe mold picking and placing device

A pick-and-place device and mold technology, applied in the direction of manufacturing tools, manipulators, chucks, etc., can solve problems such as danger, achieve the effects of pick-and-place safety, improve work reliability, and avoid danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

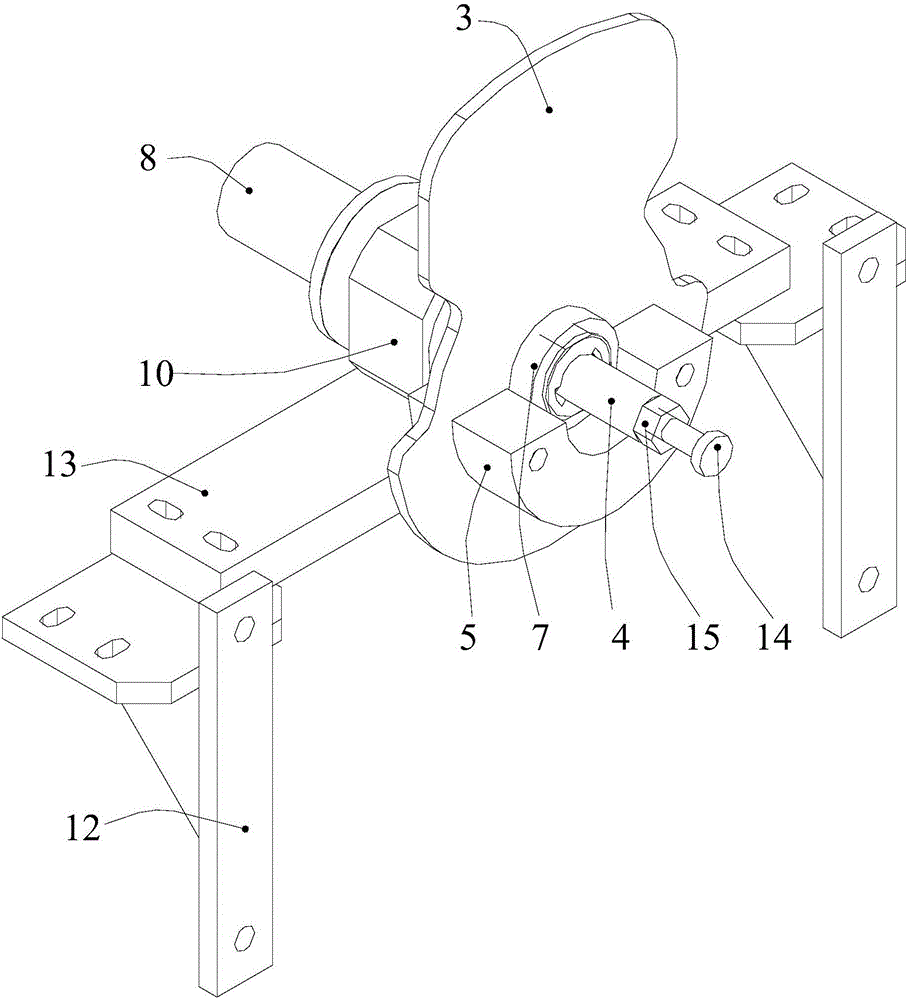

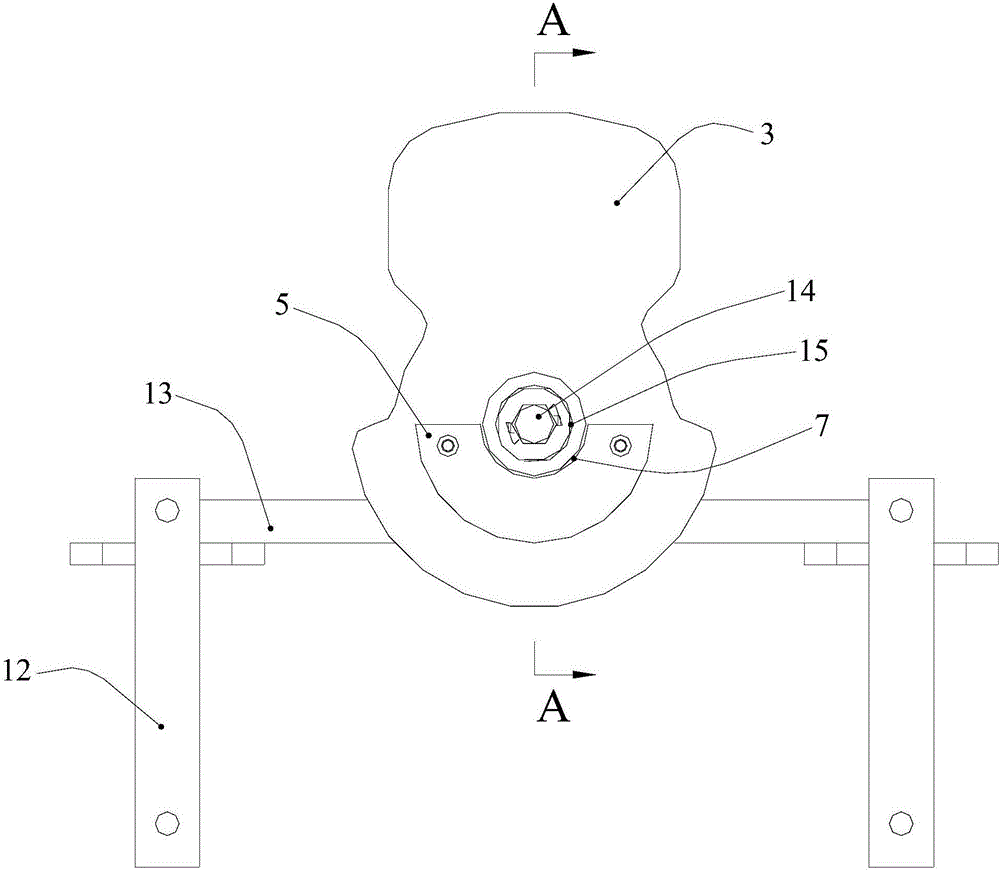

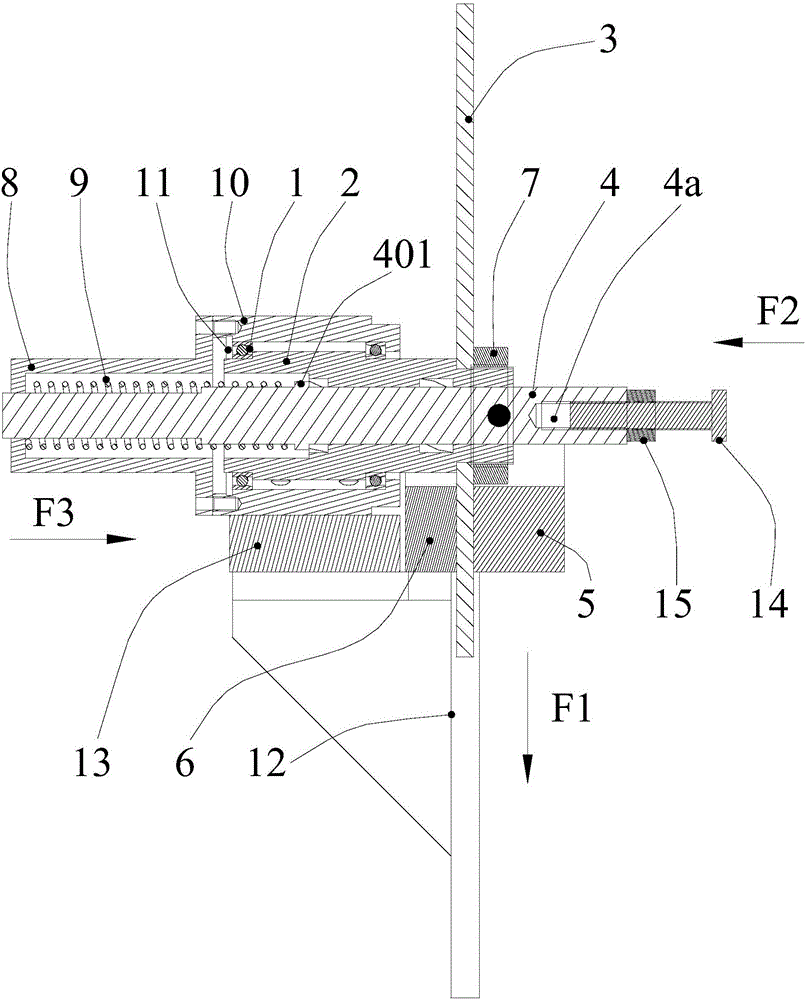

[0022] like Figure 1 to Figure 4 As shown, the mold safe pick-and-place device of the present invention is provided with a bearing 1, a wire cylinder 2, a baffle plate 3, a screw mandrel 4, a pre-action force mechanism and a mounting mechanism; the bearing 1 preferably adopts an angular contact bearing, and the bearing 1 is installed on the installation In terms of mechanism, the outer ring of the bearing 1 is relatively fixed to the mold placement frame; the wire tube 2 is fixedly installed in the inner ring of the bearing 1, and the baffle 3 is fixed on the wire tube 2, so that the baffle 3 can go around the axis of the bearing 1 Rotation; the pre-action force mechanism can apply a pre-action force F1 to the baffle plate 3, so that the baffle plate 3 rotates to the blocking position under the drive of the pre-action force F1, and the baffle plate 3 can block the mold placement frame when it is in the blocking position The inlet and outlet for picking and placing the mold; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com