Movable drilling and milling robot system achieving automatic addressing

A robot system and automatic addressing technology, applied in the field of robot systems, can solve the problems of not being used as processing equipment and the system workflow is not described, so as to reduce time and cost and improve flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

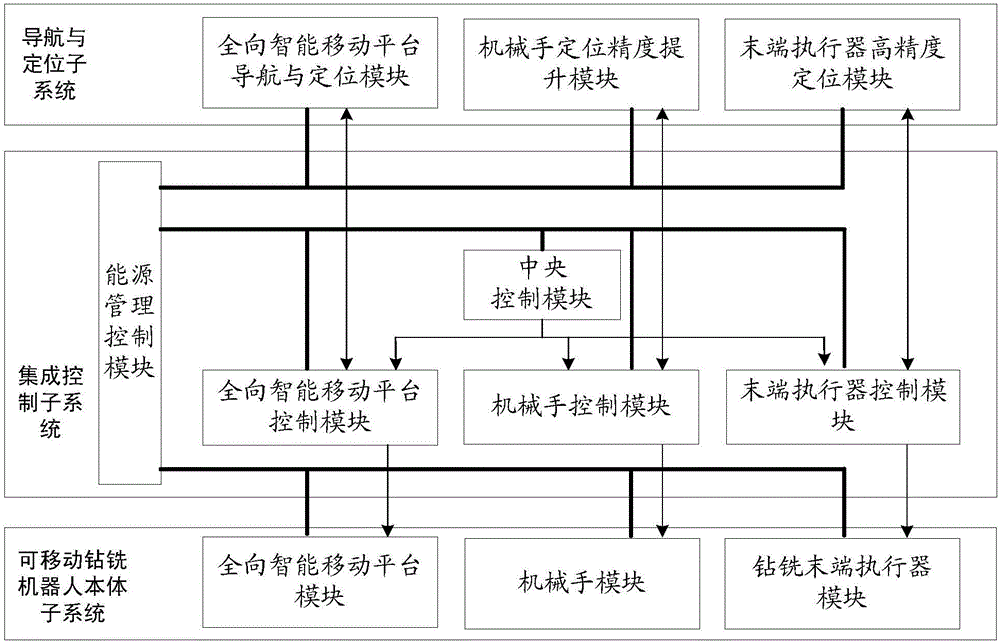

[0017] The composition of a movable automatic addressing drilling and milling robot system of the present invention is as follows: figure 1 As shown, it includes the mobile drilling and milling robot body subsystem, integrated control subsystem, navigation and positioning subsystem, of which:

[0018] The navigation and positioning subsystem includes the navigation and positioning module of the omnidirectional intelligent mobile platform, the positioning accuracy improvement module of the manipulator, and the high-precision positioning module of the end effector. This subsystem is the positioning system of the mobile automatic addressing drilling and milling robot system, which obtains the telemetry data of each module in the main body subsystem of the mobile drilling and milling robot, and provides it to the integrated control subsystem.

[0019] The telemetry data here includes the pose and velocity of each module in the main body subsystem of the mobile drilling and milling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com