Semi-automatic proofing punching and marking-out instrument, punching machine and using method

A semi-automatic, sample punching technology, applied in the direction of striking tools, manufacturing tools, center blunderbuss, etc., can solve the problems of scrapping, inaccessibility of center drills, and inability to form workpieces, etc., and achieves strong operability, high safety, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following implementation. example.

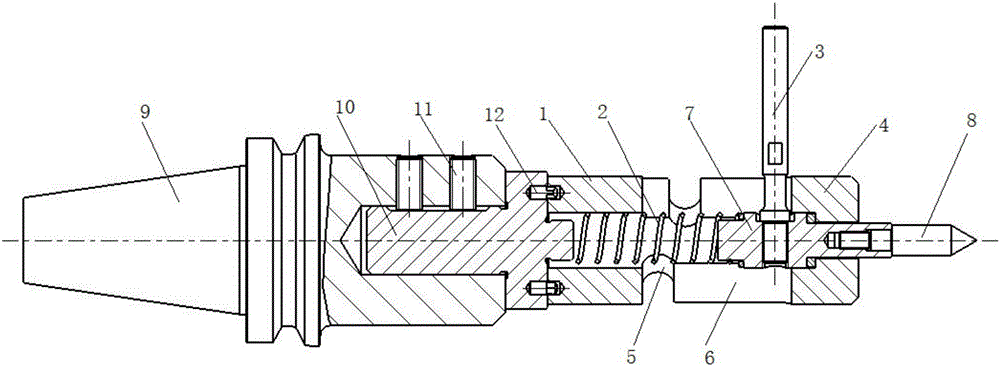

[0020] like figure 1 As shown, a semi-automatic proofing, punching and scribing tool of this embodiment includes a sleeve 1, a spring 2, a handle 3, a stopper, a top cap 4, and a punching piece; the spring 2 is sleeved on the In the sleeve 1, a through hole is opened in the top cap 4, one end of the punching member is connected to the spring 2, the other end is sleeved in the through hole of the top cap 4, and the handle 3 is connected to the punching hole. The two ends of the limiter are respectively connected to the sleeve 1 and the top cap 4, the limiter is axially provided with a through slot for the punching par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com