A jig for assembling a steel ball guide rail type intermediate shaft of a steering system and an assembling method thereof

A technology of steering system and intermediate shaft, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of long assembly hours, high trial production cost, and poor accuracy, so as to improve assembly accuracy and efficiency, reduce trial production costs, shorten The effect of assembly man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

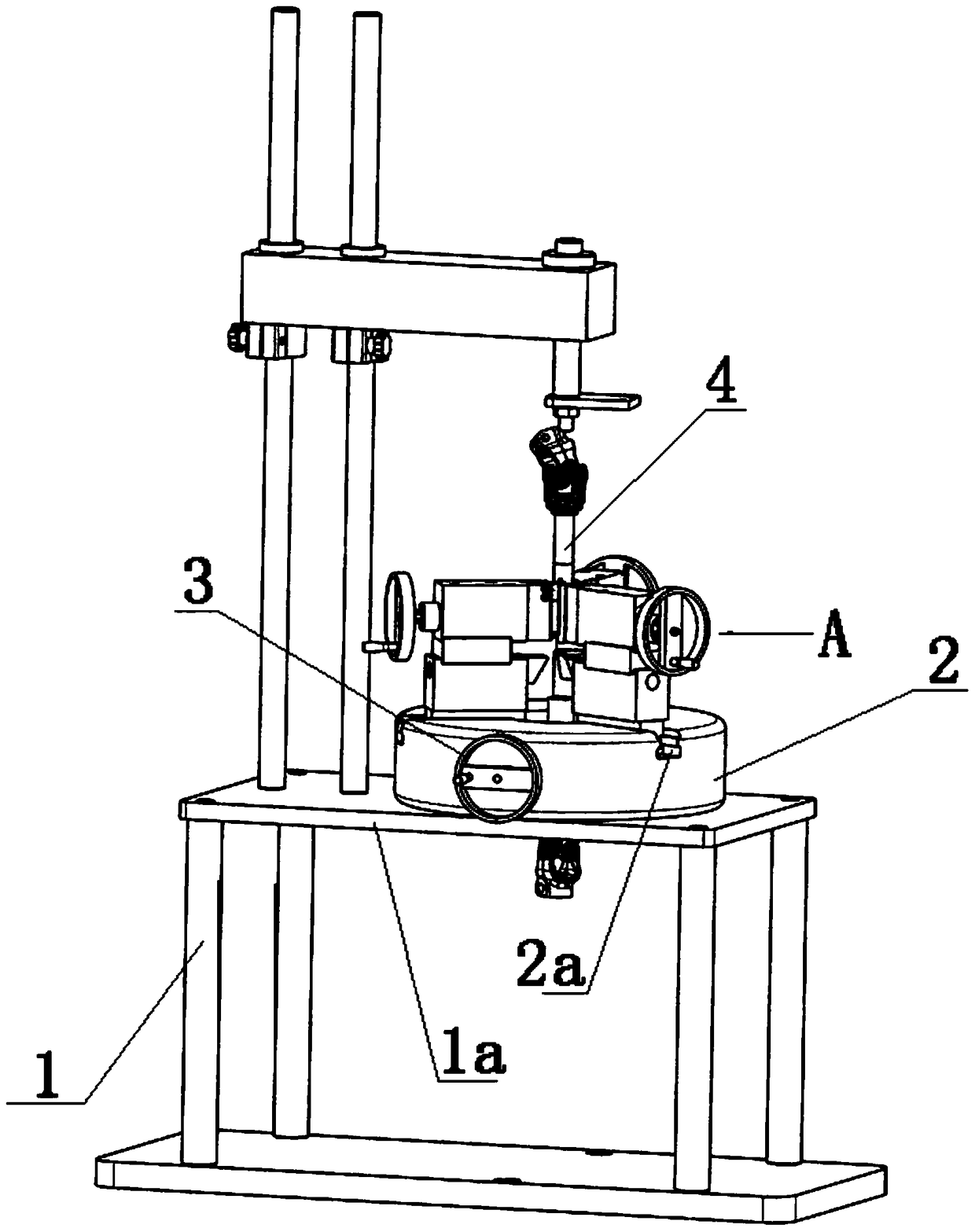

[0035] Such as Figure 1 to Figure 5 As shown, a steel ball guide rail type intermediate shaft assembly fixture for a steering system includes an assembly base 2 arranged on the support platform 1a of the bracket 1, and a clamp assembly A for intermediate shaft assembly is arranged on the base guide rail 2a of the assembly base. The clamp assembly for intermediate shaft assembly is controlled by the general hand wheel 3 arranged on one side of the assembly base 2 to expand or close;

[0036] The jig assembly A for intermediate shaft assembly clamps the position to be assembled of the ball guide type intermediate shaft 4 in the center of the jig assembly, and the steel ball 4a is loaded into the ball guide type intermediate shaft through the jig assembly for intermediate shaft assembly, and the positioning is assisted by the spring piece 4b Between the steel ball tracks 4c, the lower steering shaft 4d and the upper steering shaft 4e are socketed to form an integral steel ball g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com