Grinding Tool and Grinding Method for Square Hole of Servo Mechanism Roller Drive Piston Rod

A technology of transmission piston and servo mechanism, applied in grinding devices, grinding machine tools, work carriers, etc., can solve the problems of production quality, low production efficiency, large workload, simple and rough, etc., to improve production quality and efficiency, and reduce work The effect of reducing the amount of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

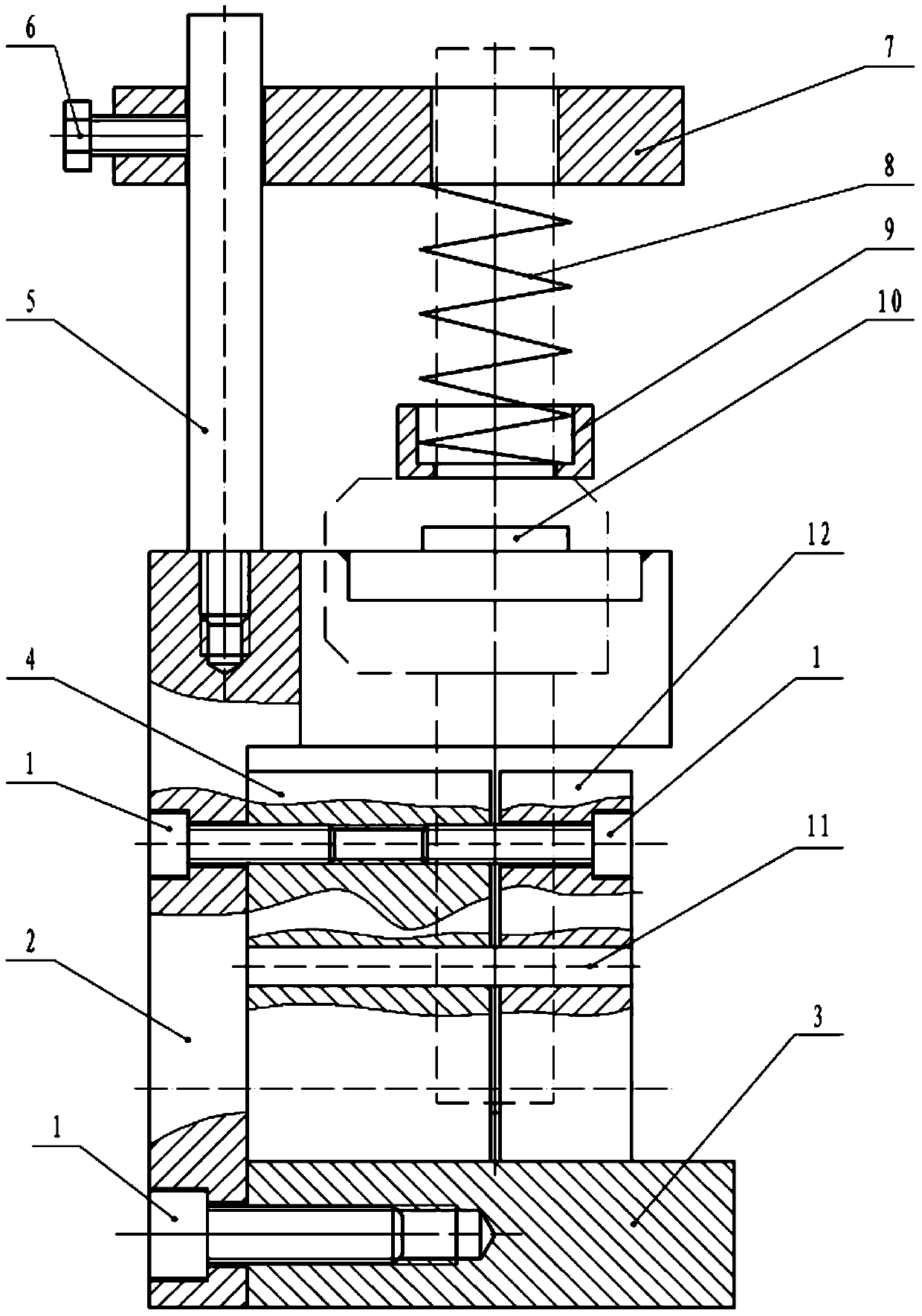

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0027] The grinding tool for the square hole of the piston rod driven by the servo mechanism roller, the device includes a base 3, a bracket assembly 2 fixed to the base 3 by screws 1, a fixed block 4 fixed to the side of the bracket assembly 2 by screws 1 and located on the upper part of the base 3, The slider 12 fixed on the side of the fixed block 4 and located on the upper part of the base 3 through the screw 1, the vertical rod 5 screwed on the upper part of the bracket assembly, the pressure plate 7 fixed on the vertical rod 5 by the bolt 6 and can move up and down, and one end is fixed on the The spring 8 at the lower end of the middle hole of the pressure plate 7, the spring holder 9 fixed on the other end of the spring 8, the fixed block 4 and the slider 12 have relative V-shaped grooves, and the combination of the V-shaped grooves is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com