Quartz swing plate substrate and preparation method thereof

A quartz swing piece and quartz glass piece technology, applied in the field of optical components, can solve the problems of poor parallelism and thickness consistency of the quartz glass disc, difficult detection of the thickness of the quartz glass disc, complicated grinding and polishing processes, etc., and improve the operability. performance and accuracy, saving materials, and eliminating processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

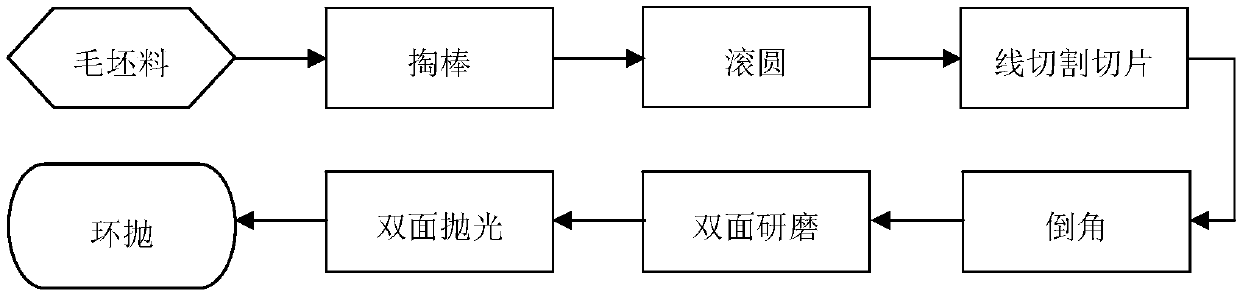

[0030] A preparation method for a quartz swing plate substrate, comprising the following steps:

[0031] (1) Rod extraction: Use a rod extraction machine to extract rods from quartz glass raw materials. The drill bit used is a copper sintered diamond cylindrical drill bit with a diamond mesh of 150-1000 mesh. / min, the diameter of the rod is 2-4mm larger than the diameter of the quartz pendulum substrate to be prepared;

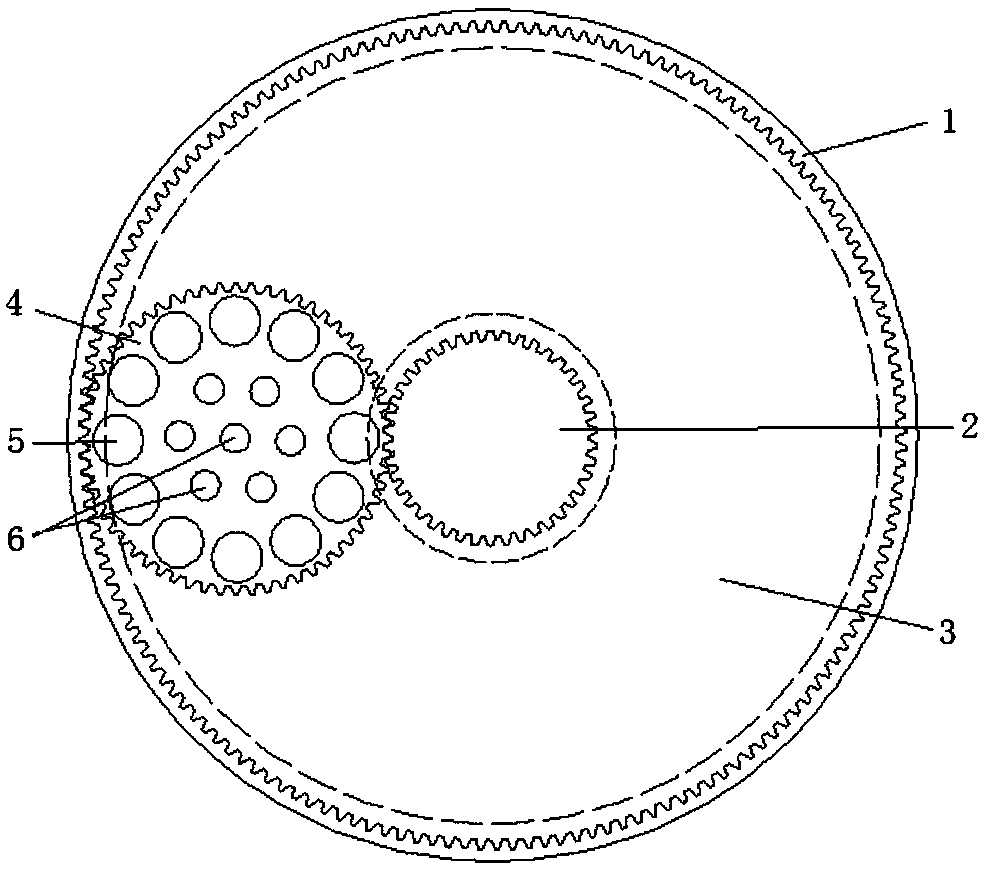

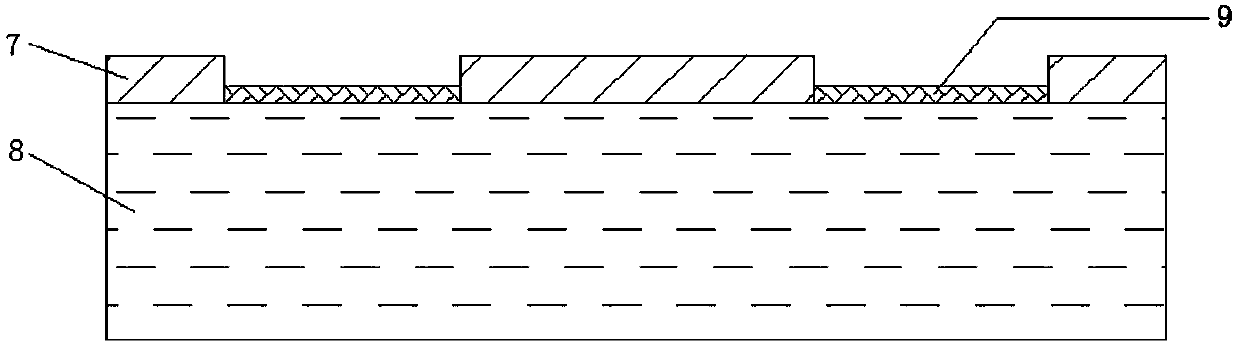

[0032] (2) Spheronization: Use a cylindrical grinder to carry out cylindrical grinding on the bar. The used grinding wheel is a resin sintered diamond grinding wheel not less than #320, and the feed speed of the grinding wheel is not greater than 0.1mm / min. The diameter of the material is ground to the size of the quartz pendulum substrate;

[0033] (3) Wire-cut slicing: use a multi-wire cutting machine to cut the bar stock into quartz glass sheets by wire-cutting. The used wire rod is a 0.1-0.3mm electroplated diamond cutting wire with a diameter of 0.1-0.3...

Embodiment 1

[0054] Taking the processing of a quartz pendulum substrate with a diameter of 22.200±0.010mm and a thickness of 0.700±0.005mm as an example to illustrate the processing method, it includes the following steps:

[0055] 1. Rod extraction: Place the quartz glass raw material in the processing area of the rod extraction machine and fix it. Use the #150 copper sintered diamond sleeve drill bit to drill the bar material at the selected position of the quartz glass ingot. The drill bit rotates at 2000r / min during processing. , the feed speed is 3mm / min, and the bar diameter is 25-26mm.

[0056] 2. Rounding: place the quartz glass bar between the headstock and the tailstock of the cylindrical grinder, and use #320 resin diamond grinding wheel to grind the outer circle of the quartz glass bar. The feed speed of the grinding wheel is 0.1mm during the processing / min, the diameter of the quartz glass cylinder after grinding is 22.200±0.010mm.

[0057] 3. Wire-cut slicing: fix the qu...

Embodiment 2

[0063] Taking the processing of a quartz pendulum substrate with a diameter of 25.000±0.010mm and a thickness of 0.750±0.005mm as an example to illustrate the processing method, it includes the following steps:

[0064] 1. Rod extraction: Place the quartz glass raw material in the processing area of the rod extraction machine and fix it. Use the #500 electroplated diamond sleeve drill bit to drill the bar material at the selected position of the quartz glass ingot. The drill bit speed is 3000r / min during processing. The feed rate was 5mm / min and the bar stock diameter was 27-28mm.

[0065] 2. Rounding: place the quartz glass bar in the working area of the centerless grinder, use #400 resin diamond grinding wheel to grind the outer circle of the quartz glass bar, the feed speed of the grinding wheel is 0.1mm / min during the processing, and after grinding The diameter of the quartz glass cylinder is 25.000±0.010mm.

[0066]3. Wire-cut slicing: fix the quartz glass cylinder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com