Alignment Tooling and Alignment Method for Multiple Crankshafts of Hybrid Fiber Multiaxial Warp Knitting Machine

A hybrid fiber and warp knitting machine technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of hidden stress concentration, increase the number of crankshaft processing steps, destroy the integrity of the main journal structure, etc., to improve assembly accuracy, Effect of reducing machining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

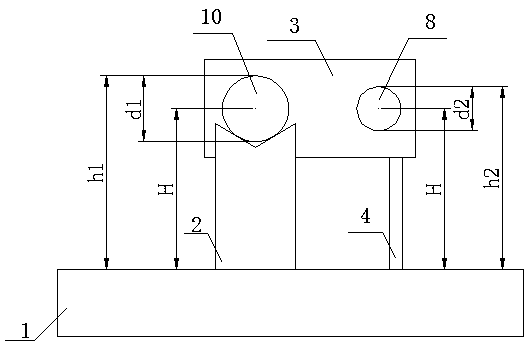

[0031] Such as figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a side view of the L-shaped adjustment block of the present invention, image 3 It is a schematic diagram of measuring main journal and connecting rod shaft diameter in the present invention, Figure 4 It is a schematic diagram of crankshaft assembly centering in the present invention, Figure 5 It is a side view of the working V block of the present invention, a multi-crankshaft centering tool for a hybrid fiber multi-axial warp knitting machine, including a crankshaft 3, on which a main journal 10 and a connecting rod journal 8 are arranged, and a flat plate 1, a V Block 2, screw lifting device 4, adjuster 5, L-shaped adjustment block 6, horizontal plate 7 and coupling 9, V block 2 is placed on plate 1, main journal 10 is placed on V block 2, connecting rod journal A screw lifting device 4 is placed on the flat plate 1 directly below 8, an adjuster 5 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com