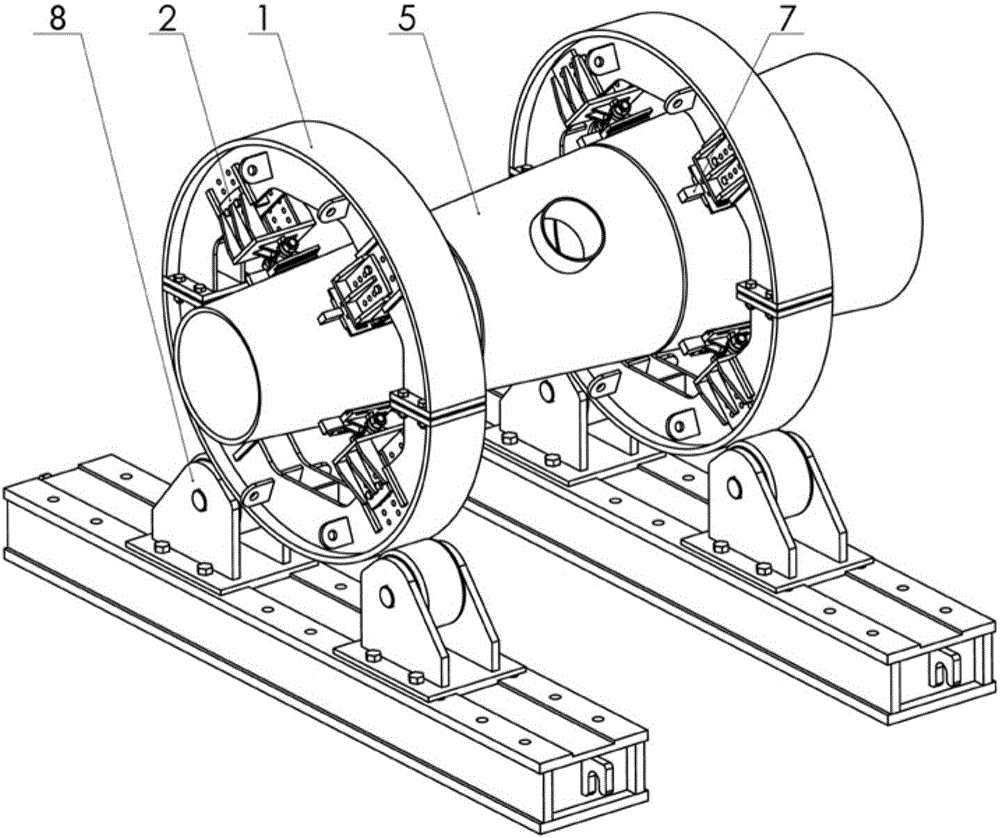

Horizontal rotating device for conical barrel body

A conical cylinder, horizontal rotation technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as deformation of the clamping position of the cone, bumping against the outer wall parts of the cone, and inability to install the nozzle accurately. , to achieve the effect of easy installation and disassembly, strong adaptability and good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

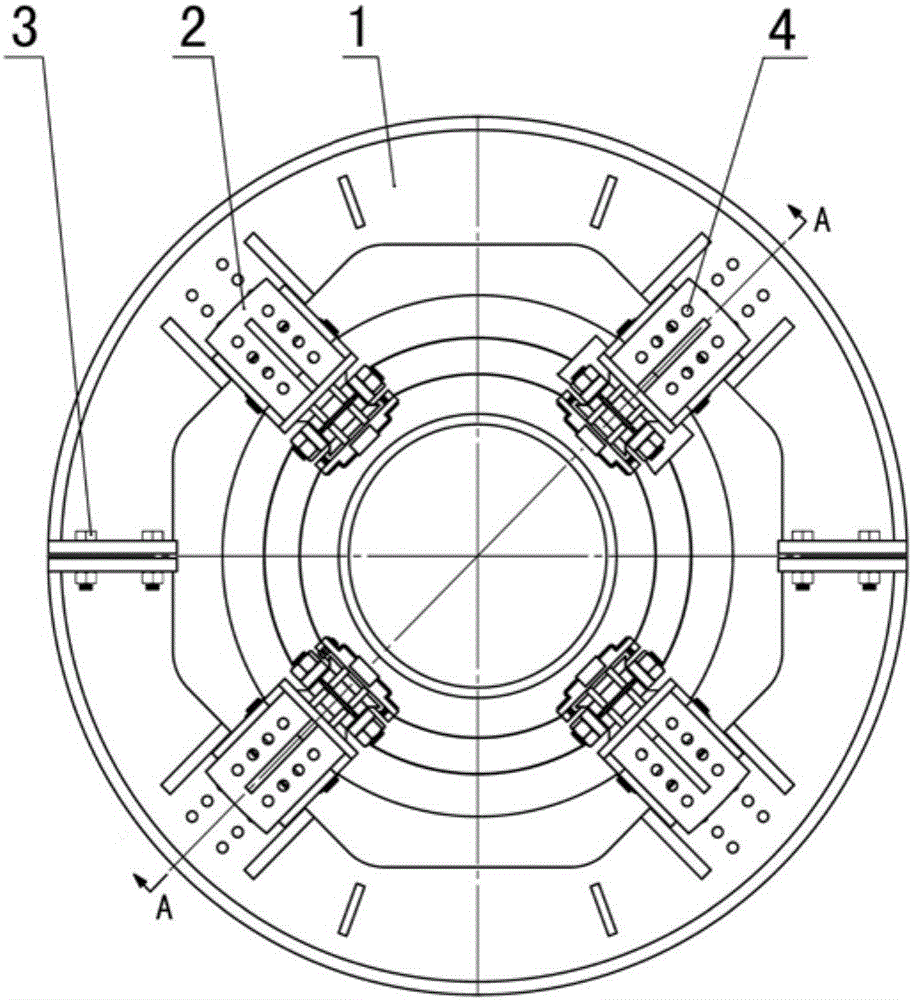

[0064] According to another embodiment of the present invention, preferably each semicircular member constituting the support ring 1 includes an arc plate 1-1, a side plate 1-2, a lifting lug 1-3, a guide plate 1-4, a rib plate 1- 5 and connecting plates 1-6.

[0065] Such as Figure 4 As shown, the side plate 1-2 is a steel plate with a circular outer edge and a regular polygon inside, preferably a regular octagon, and the holes on both sides are the connecting holes of the hinge seat 2, and the joint hinge seat is processed after the overall welding is completed. The centerlines of the two holes have an included angle of 90° and are symmetrical along the centerline of the support ring 1, and the inner sides of the two side plates are welded and connected by ribs 1-5.

[0066] In the present invention, the guide plates 1-4 play a guiding role when installing and adjusting the installation positions of the hinge base 2 and the support ring 1 . The ribs 1-5 are multiple pieces,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com