Intelligent supply device

A feeding device, intelligent technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems that cannot meet the development needs, and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

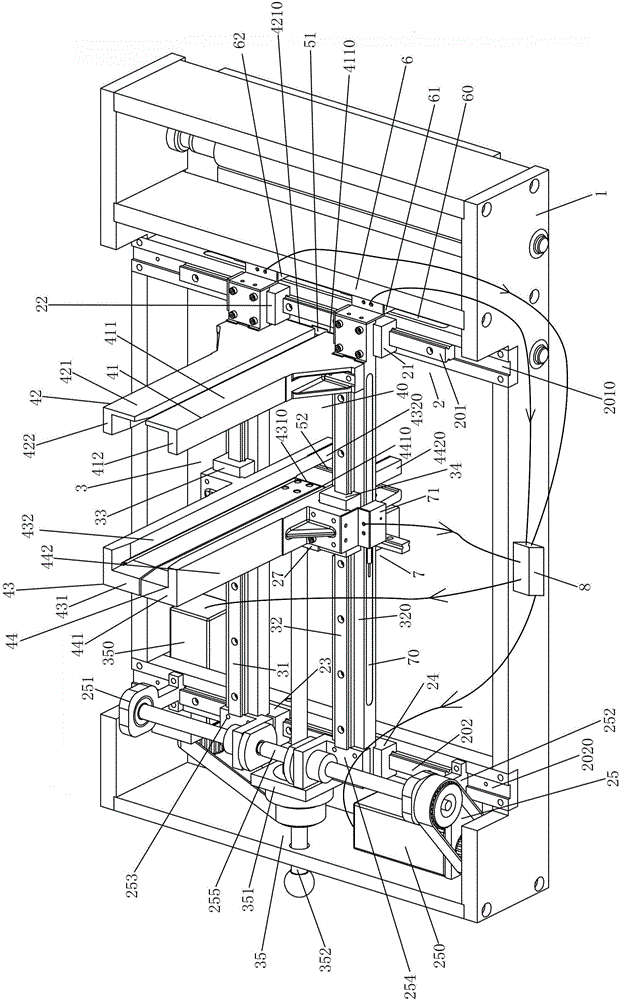

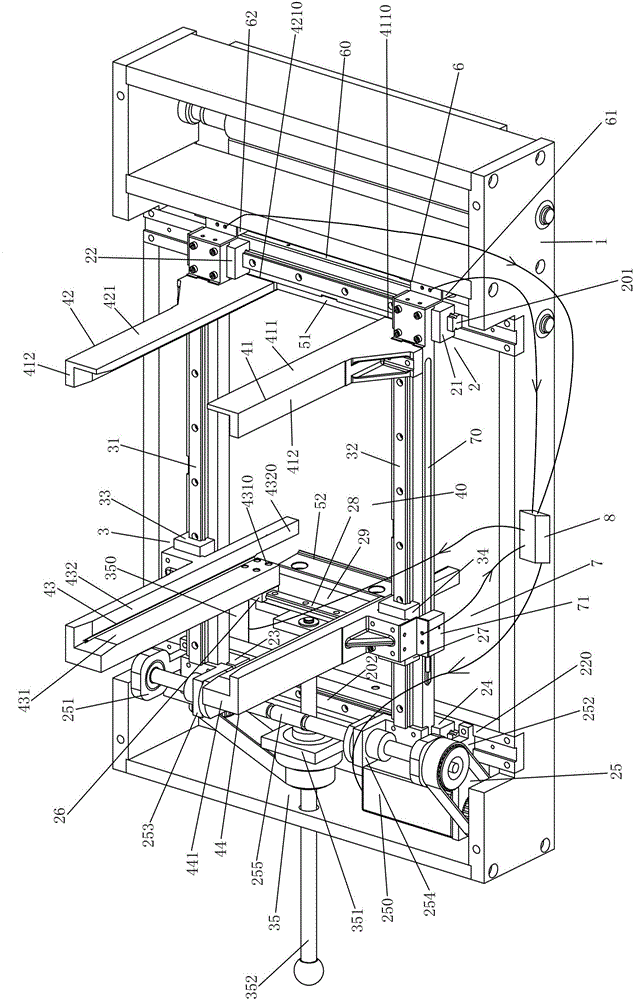

[0070] Such as figure 1 and figure 2 As shown, the intelligent feeding device in this preferred embodiment includes a frame 1, a longitudinal opening and closing mechanism 2, a transverse opening and closing mechanism 3, a first right-angle limit rod 41, a second right-angle limit rod 42, a third right-angle limit rod The limit rod 43 , the fourth right-angle limit rod 44 , the first pallet 51 , the second pallet 52 , the longitudinal displacement incremental detection mechanism 6 , the lateral displacement incremental detection mechanism 7 and the controller 8 .

[0071] The above-mentioned longitudinal opening and closing mechanism 2 includes a first longitudinal guide rail 201, a second longitudinal guide rail 202, a first longitudinal slider 21, a second longitudinal slider 22, a third longitudinal slider 23, a fourth longitudinal slider 24, a longitudinal opening and closing Drive mechanism 25, first longitudinal auxiliary slide block 26, second longitudinal auxiliary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com