Automatic express sorting machine

An automatic sorting and express delivery technology, applied in the direction of sorting, etc., can solve the problems of unsuitable distribution points and small and medium-sized transfer yards, high personnel costs, and labor-intensive problems, so as to achieve a short cost recovery cycle and save The effect of low labor cost and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

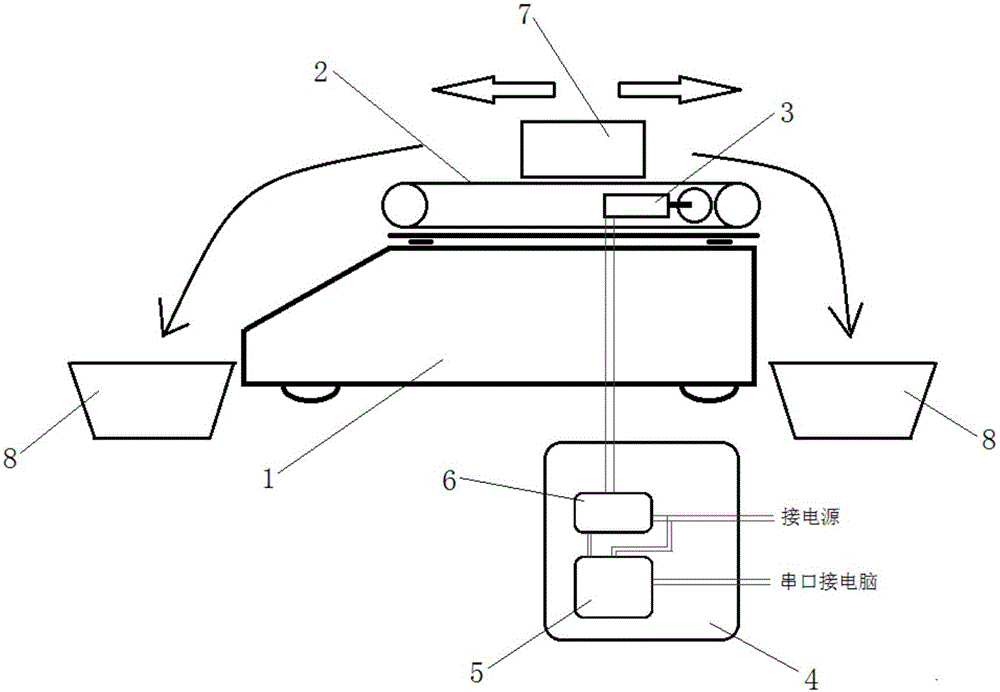

[0021] Such as figure 1 As shown, an express automatic sorting machine includes a weighing device 1, a conveying device 2, a driving device 3 and a controller 4, the conveying device 2 is connected with the driving device 3 and is driven by the driving device 3, and the driving device 3 is Two-way driving device, the driving device 3 is connected with the controller 4; the transmission device 2 is located on the weighing pan of the weighing device 1, and the sensor inside the weighing device 1 is connected with the controller.

[0022] The sensor of the weighing device 1 is connected to the controller 4 through the server, and the package scanner is also connected to the server. The server generates a code according to the code scanning signal of the scanner and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com