Preparation method of carbon-loaded Ru base catalyst by carbon thermal reduction

A catalyst and carbothermal technology, applied in the field of catalytic chemistry, can solve the problems of long time consumption, poor dispersion, loss of metal components, etc., and achieve the effects of increasing the load, saving reducing agents, and avoiding danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After the activated carbon carrier was ground and sieved to 80-100 meshes, it was placed in an oven at 120°C and dried overnight; an equal-volume impregnation method was used to prepare a ruthenium trichloride precursor impregnation solution equal to the saturated water absorption of the carrier, and slowly added to the carrier while stirring. It was mixed evenly, and after ultrasonic treatment, it was left to stand for 24 hours, and then dried overnight in an oven at 110° C. to obtain a powder catalyst precursor (Ru(Cl) / AC) with a loading of 5 wt%.

Embodiment 2

[0026] Take an appropriate amount of the above-mentioned catalyst precursor Ru(Cl) / AC and place it in a quartz tube. Under an Ar atmosphere of 25ml / min, the temperature is raised to 250°C, 350°C, and 450°C for 3 hours at a constant temperature of 3°C / min. Ru / AC-C-250, Ru / AC-C-350, Ru / AC-C-350 were obtained.

Embodiment 3

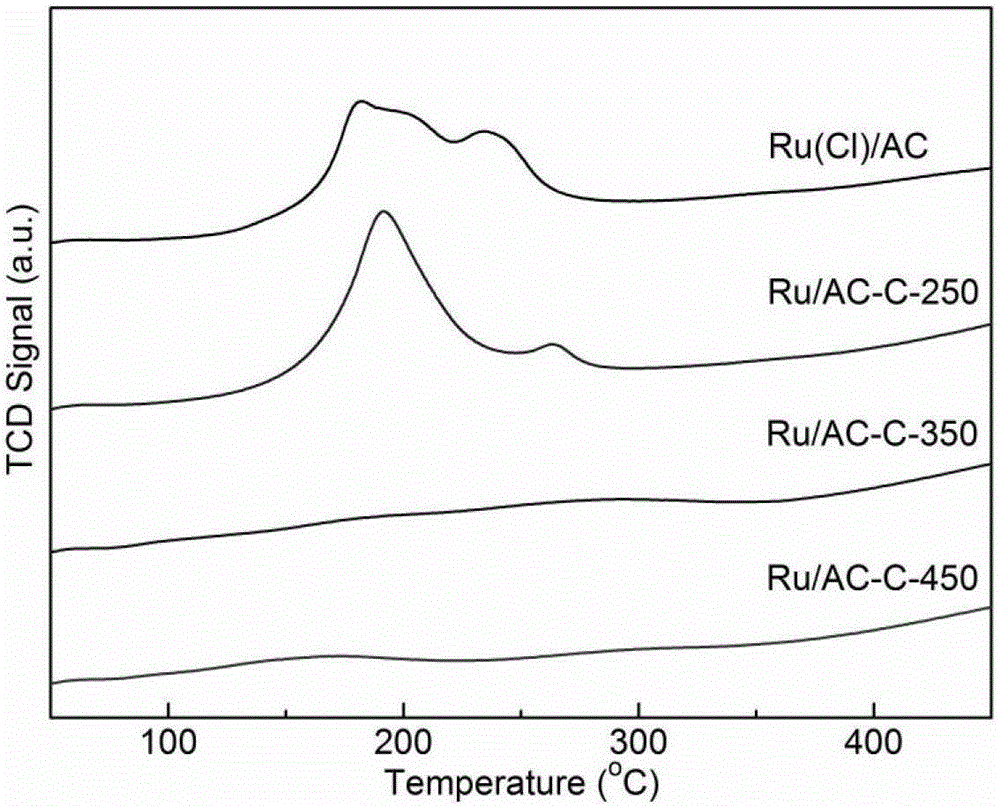

[0028] h 2 -TPR characterization: take appropriate amount of three kinds of catalyst samples and catalyst precursor Ru(Cl) / AC in the above-mentioned embodiment 2 and place them in a U-shaped quartz tube. 2 / Ar atmosphere, the temperature was programmed to 600°C at 10°C / min. Characterization results such as figure 1 As shown, the results show that in an inert atmosphere, Ru(Cl) / AC can undergo carbothermal reduction to Ru / AC-C at a temperature range above 350 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com