A kind of preparation method of cuprous oxide/melamine sponge used for oil spill recovery

A technology of melamine sponge and cuprous oxide, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of expensive production cost, inconvenient oil spill recovery, and limited wide application, and achieve The effect of low price, good recycling performance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

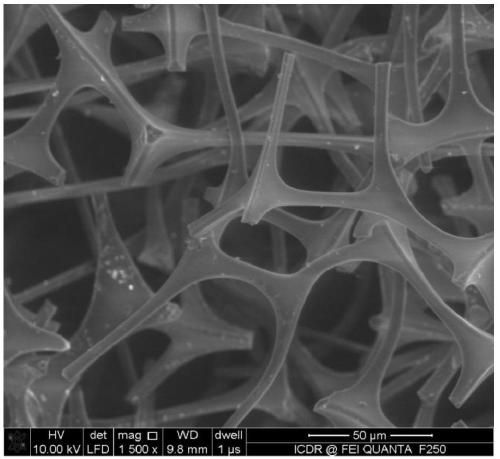

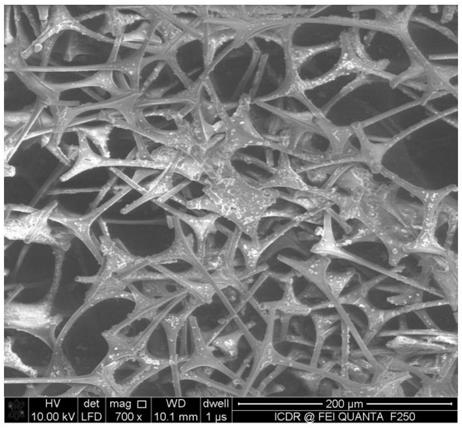

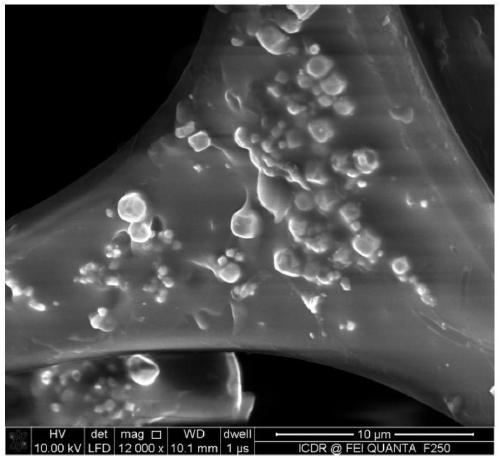

[0026] Depend on figure 1 And Figure 2 can see the SEM characterization figure of untreated melamine sponge and the melamine sponge made based on cuprous oxide modification, it can be seen that the untreated melamine sponge outline wall surface is smooth, and the melamine made based on cuprous oxide modification A lot of cuprous oxide particles are compounded on the outline wall surface of the sponge, which shows that the cuprous oxide of the present invention and the melamine sponge are well compounded.

[0027] Depend on image 3 Can see the apparent state figure of melamine sponge and its modified material in water, unmodified melamine sponge is to sink to the bottom of the water, and the melamine sponge that makes based on cuprous oxide modification floats on the water surface, this shows that the present invention The melamine s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com