Filtering material with antibacterial function and preparation method thereof

A filter material and functional technology, which is applied in the field of filter material with antibacterial function and its preparation, can solve the problems of low filtration efficiency, large resistance pressure drop, and poor antibacterial performance, and achieve high filtration efficiency, large resistance pressure drop, and enhanced The effect of antimicrobial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

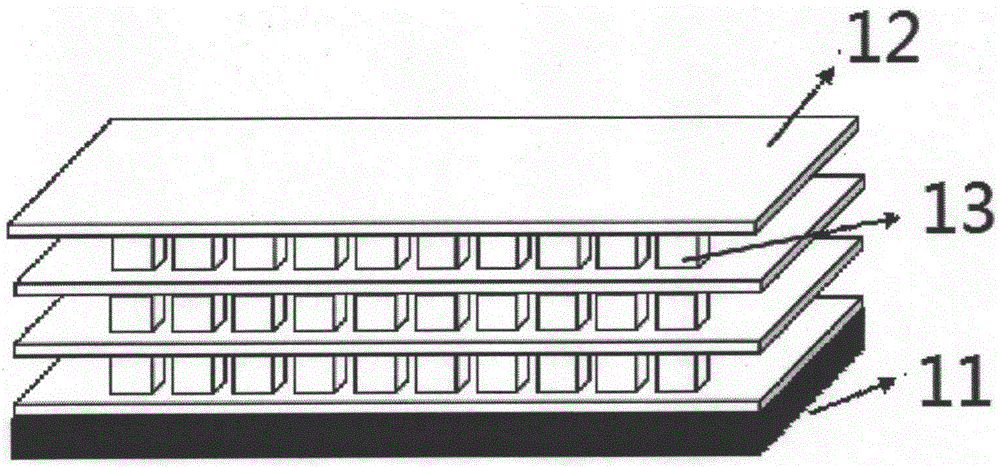

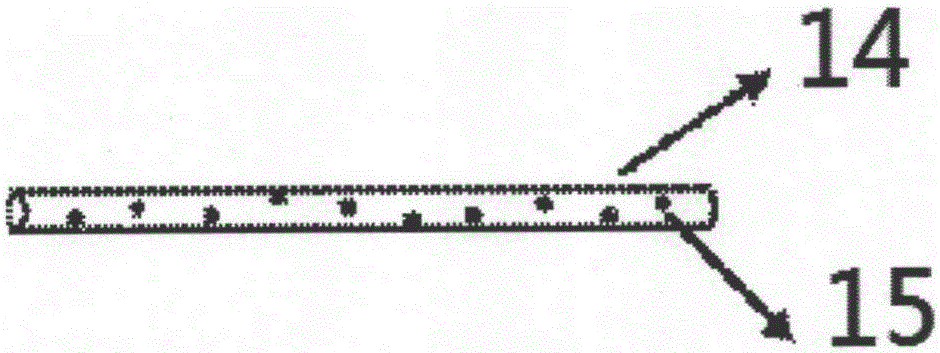

[0043] like figure 1 As shown, the filter material with antibacterial function in this embodiment is composed of a substrate 11 and a nanofiber membrane arranged on the substrate 11. The nanofiber membrane includes hierarchical units, and each hierarchical unit includes nanofibers 14 The planar layer 12 formed by disorderly aggregation and the cavity structure 13 formed by directional arrangement and stacking of nanofibers 14 arranged on the planar layer 12, part of the cavity structure 13 is filled with substances 15 with antibacterial function, and the nanofibers 14 It is also doped with substances 15 that have antibacterial properties. The nanofibrous membrane also includes a planar layer 12 composed of randomly assembled nanofibers, and the planar layer 12 is arranged on the uppermost hierarchical unit.

[0044] The grammage of substrate 11 is 10g / m 2 , the material is polyvinyl chloride, it is mesh-shaped, and the mesh size is 1mm 2 . . The porosity of the nanofiber ...

Embodiment 2

[0052] like figure 1 As shown, the filter material with antibacterial function in this embodiment is composed of a substrate 11 and a nanofiber membrane arranged on the substrate 11. The nanofiber membrane includes hierarchical units, and each hierarchical unit includes nanofibers 14 The planar layer 12 formed by disorderly aggregation and the cavity structure 13 formed by directional arrangement and stacking of nanofibers 14 arranged on the planar layer 12, part of the cavity structure 13 is filled with substances 15 with antibacterial function, and the nanofibers 14 It is also doped with substances 15 that have antibacterial properties. The nanofibrous membrane also includes a planar layer 12 composed of randomly assembled nanofibers, and the planar layer 12 is arranged on the uppermost hierarchical unit.

[0053] Substrate 11 gram weight is 20g / m 2 , the material is metal, mesh shape, the mesh size is 1mm 2 . The porosity of the nanofiber membrane is 99.9%, the average ...

Embodiment 3

[0062] like figure 1 As shown, the filter material with antibacterial function in this embodiment is composed of a substrate 11 and a nanofiber membrane arranged on the substrate 11. The nanofiber membrane includes hierarchical units, and each hierarchical unit includes nanofibers 14 The planar layer 12 formed by disorderly aggregation and the cavity structure 13 formed by directional arrangement and stacking of nanofibers 14 arranged on the planar layer 12, part of the cavity structure 13 is filled with substances 15 with antibacterial function, and the nanofibers 14 It is also doped with substances 15 that have antibacterial properties. The nanofibrous membrane also includes a planar layer 12 composed of randomly assembled nanofibers, and the planar layer 12 is arranged on the uppermost hierarchical unit.

[0063] Substrate weight is 40g / m 2 , the material is polypropylene, mesh shape, the mesh size is 1mm 2 . . The porosity of the nanofiber membrane is 99%, the average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com