Glabridin nanosuspension and preparation method thereof

A technology of nano-suspension and glabridin, which is applied in the field of beauty and skin care cosmetics, can solve the problems of low solubility, unsatisfactory transdermal absorption effect, and limitations, and achieve the effect of simple process, accurate dosage, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

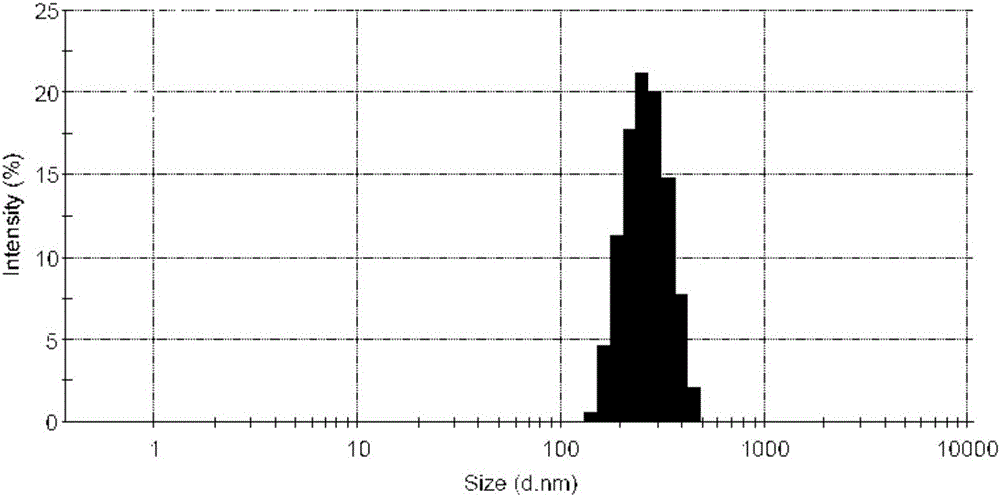

[0020] Add 0.8 g of glabridin into 80 ml of aqueous solution containing 0.4 g of Tween 80 under stirring, and ultrasonicate at 500 W for 30 seconds to form a rough suspension of glabridin. Transfer the glabridin crude suspension to a pre-cooled high-pressure homogenizer at 0-5°C for homogenization, first cycle 5 times at 500 bar, and then cycle 15 times at 1300 bar to obtain glabridin nano-suspension , The average particle diameter of the nanosuspension was measured to be 342nm. Particle size distribution as figure 1 As shown, it shows that the particle size distribution range is uniform.

Embodiment 2

[0022] Add 1 g of glabridin into 100 ml of aqueous solution containing 0.5 g of poloxamer 188 under stirring, and ultrasonicate at 500 W for 30 seconds to form a coarse suspension of glabridin. Transfer the glabridin crude suspension to a pre-cooled high-pressure homogenizer at 0-5°C for homogenization, first cycle 5 times at 500 bar, and then cycle 15 times at 1300 bar to obtain glabridin nano-suspension , The average particle diameter of the nanosuspension was measured to be 395nm.

Embodiment 3

[0024] Add 2 g of glabridin into 50 ml of aqueous solution containing 0.1 g of sodium lauryl sulfate under stirring, and ultrasonicate at 500 W for 30 seconds to form a rough suspension of glabridin. Transfer the glabridin crude suspension to a pre-cooled high-pressure homogenizer at 0-5°C for homogenization, first circulate 5 times at 500 bar, and then circulate 12 times at 1400 bar to obtain glabridin nano-suspension , The average particle diameter of the nanosuspension was measured to be 591nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com