Elastic bone screw

A bone screw and elastic technology, applied in the field of bone screws, can solve problems such as reduced friction, difficulty in forming a dynamic elastic structure, deformation or fracture of steel plates, etc., and achieves the effects of increased welding reliability, increased torsional force, and less breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

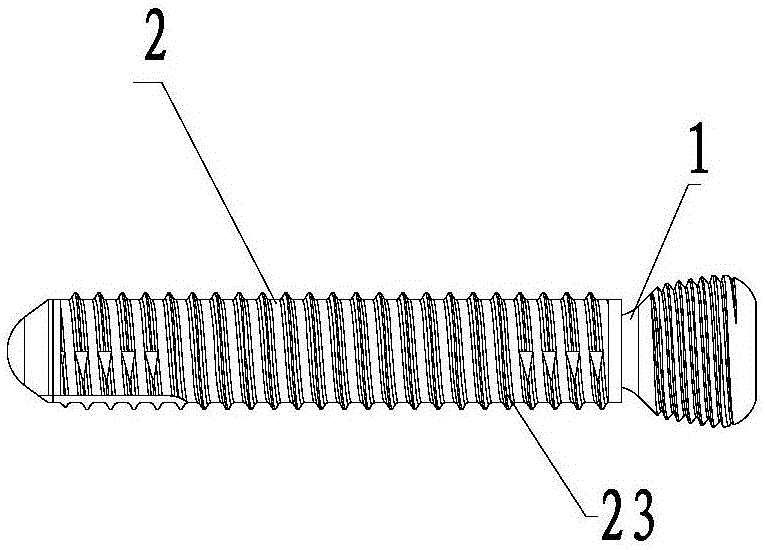

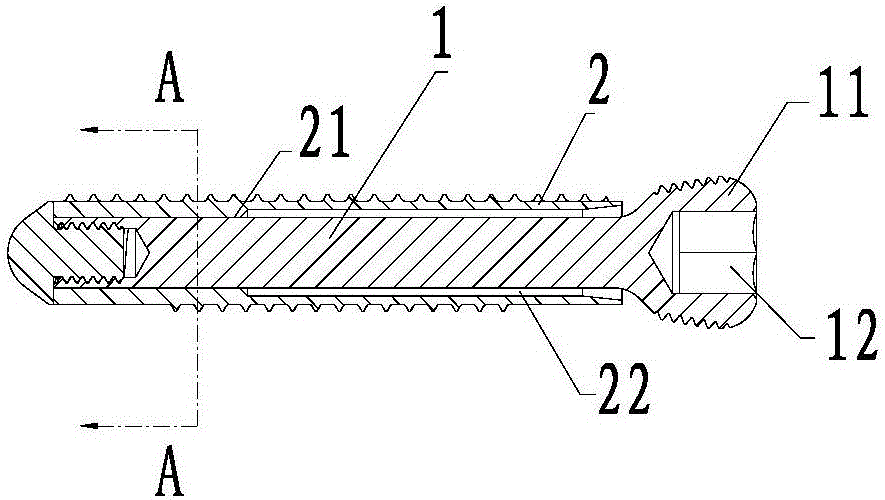

[0034] refer to Figure 1-8 , an elastic bone screw, comprising an elastic rod 1 and a limiting sleeve 2; a part of the elastic rod 1 is inserted into the limiting sleeve 2 along the axial direction of the limiting sleeve 2; one end of the elastic rod 1 It is fixedly connected with the slot 21 in the limiting sleeve 2, and the other end is provided with a locking joint 11, and the end surface of the locking joint 11 along the axial direction is provided with a screw groove 12; the outer periphery of the limiting sleeve 2 is provided with There are 23 threads. The rotation of the elastic rod 1 drives the limit sleeve 2 to rotate, so that the thread 23 on the outer periphery of the limit sleeve 2 is fixed and locked with the fracture.

[0035] In the part where the elastic rod 1 is inserted into the limit sleeve 2, there is a limit gap 22 between the other positions and the inner wall of the limit sleeve 2 except the position fixedly connected with the limit sleeve 2; During h...

Embodiment 2

[0044] refer to Figure 9 The difference between this embodiment and embodiment 1 is that the cross section of the part where the elastic rod 1 is fixedly connected with the limiting sleeve 2 is triangular.

Embodiment 3

[0046] refer to Figure 10 The difference between Example 1 and Example 1 is that the cross-section of the part where the elastic rod 1 is fixedly connected with the limit sleeve 2 is quincunx-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com