CT coplanar puncture template provided with identifier guiding devices and making method of CT coplanar puncture template

A technology of a puncture template and a guiding device, which is applied in the field of medical equipment, can solve the problems of increased surgical risk, cumbersome use process, time-consuming, etc., and achieves the effects of reducing the number of CT scans, avoiding repeated puncture positioning, and alleviating the pain of patients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

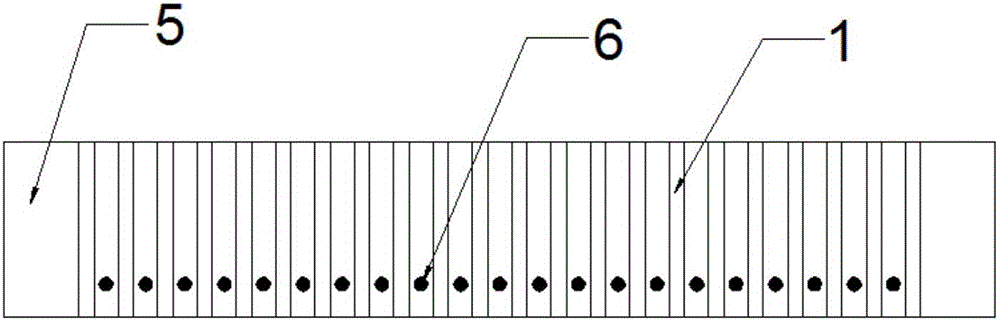

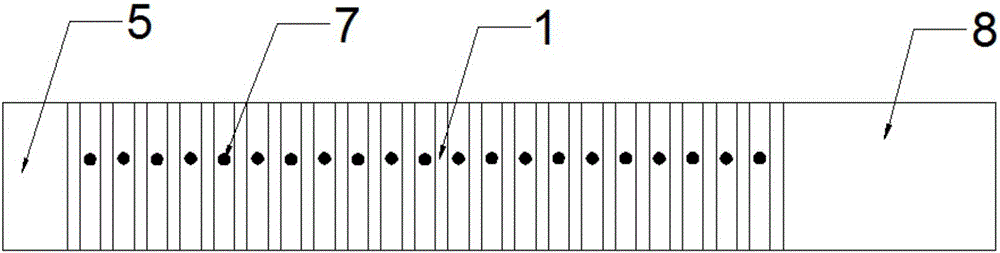

[0052] Follow the steps below to prepare a CT coplanar puncture template with an identification guide:

[0053] (1) 3D modeling: input the size information of the puncture template into the modeling software for 3D modeling. The size information includes the length of the plate body of 12 cm, width of 12 cm, and thickness of 1 cm, and the length of the fixed end of 12 cm, width of 2 cm, and thickness of 1 cm. The diameter of the puncture needle holes is 3mm, the spacing is 5mm, and the arrangement (rows and columns are neatly arranged), the position of the lead wire hole in the row (0.2cm from the upper surface), the hole diameter is 1.0mm, the position of the lead wire hole in the column (0.7cm from the upper surface), Aperture 1.0mm;

[0054] (2) Print out the puncture template with a single-hole 3D printer according to the 3D model of the established puncture template, and the printing material used is PLA;

[0055] (3) Insert a lead wire with a diameter of 0.5 mm into the...

Embodiment 2

[0061] Follow the steps below to prepare a CT coplanar puncture template with an identification guide:

[0062] (1) 3D modeling: input the size information of the puncture template into the modeling software for 3D modeling, the size information includes the length of the plate body 12cm, width 12cm, thickness 2cm, length of the fixed end 12cm, width 2cm, thickness 1.3cm , the diameter of the puncture needle holes is 1 mm, the spacing is 5 mm, and the arrangement (rows and columns are neatly arranged), the position of the lead wire holes in the rows (1.2 cm from the upper surface), the hole diameter is 1.6 mm, and the position of the lead wire holes in the columns (1.5 cm from the upper surface) , Aperture 1.6mm;

[0063] (2) Print out the puncture template with a single-hole 3D printer according to the 3D model of the established puncture template, and the printing material used is PLA;

[0064] (3) Insert a lead wire with a diameter of 1 mm into the lead wire hole, and seal...

Embodiment 3

[0069] Follow the steps below to prepare a CT coplanar puncture template with an identification guide:

[0070] (1) 3D modeling: input the size information of the puncture template into the modeling software for 3D modeling, the size information includes the length of the plate body 12cm, width 12cm, thickness 2cm, length of the fixed end 12cm, width 2cm, thickness 1.3cm , the diameter of the puncture pinholes is 1.87mm, the spacing is 5mm, and the arrangement (rows and columns are neatly arranged), the position of the row lead wire holes (0.9cm from the upper surface), the hole diameter is 1.6mm, and the position of the column lead wire holes (1.5cm from the upper surface ), aperture 1.6mm;

[0071] (2) Print out the puncture template with a single-hole 3D printer according to the 3D model of the established puncture template, and the printing material used is PLA;

[0072] (3) Insert a lead wire with a diameter of 1 mm into the lead wire hole, and seal the opening of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com