One-time heating heat-insulating water dispenser equipment

A technology for heating and heat preservation and water dispenser, which is applied in beverage preparation devices, household appliances, applications, etc., and can solve problems such as waste of power, poor heat preservation performance of heaters, and limited capacity of heaters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

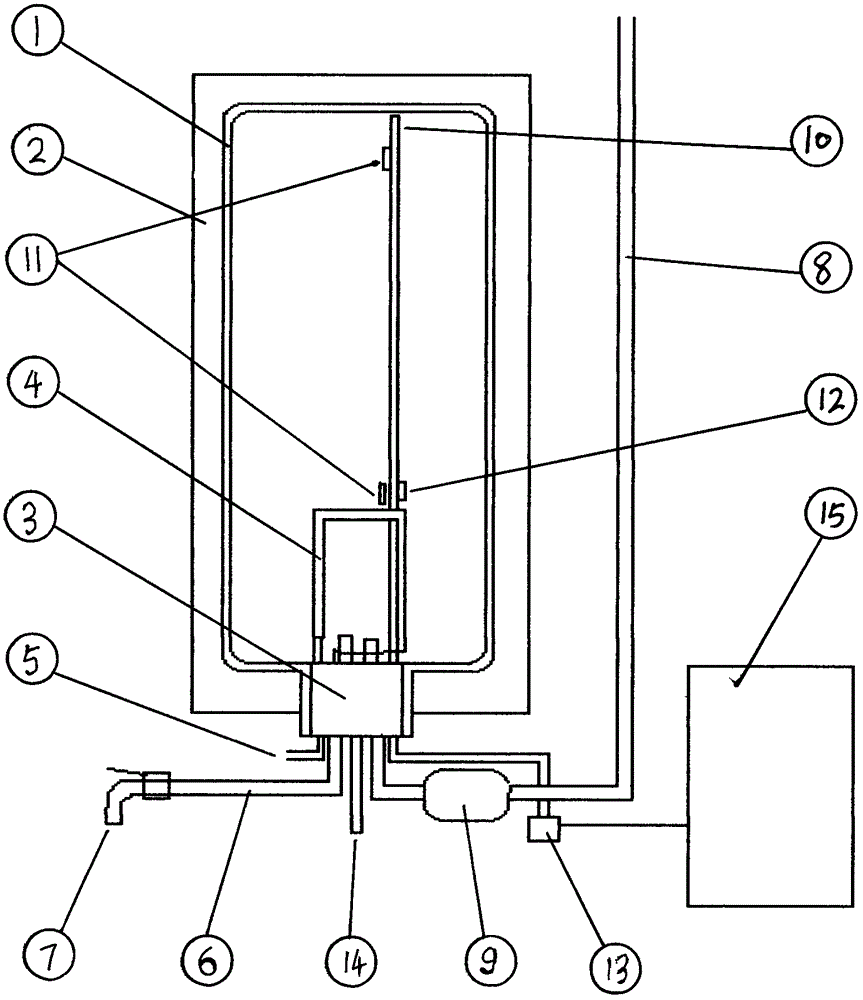

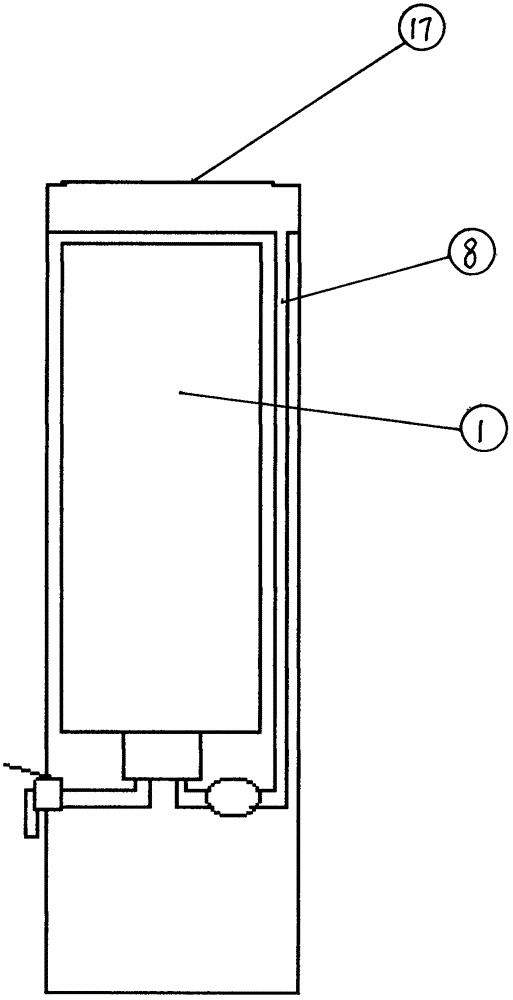

[0009] pass figure 1 It can be seen that the device is formed by installing an upper conduit on the mouth of an inverted thermos bottle. The thermos bottle (1) is made of double-layer glass, and the inside of the double-layer glass is drawn out to form a vacuum. To increase the heat preservation performance, the outside of the thermos bottle is fixed by the outer layer of thermal insulation material (2) to prevent heat loss. The mouth of the thermos bottle (1) is facing downward, and the mouth of the bottle is sealed by a sealing plug (3), and all the conduits are sealed The plug (3) enters the inside of the thermos bottle, and the electric heating tube (4) is installed above the sealing plug. When the power is turned on during operation, the water body can be heated to form boiling water. The electric heating tube is connected to the external 220V power connector (5) to connect the heating The power supply and the water outlet pipe (6) enter the interior of the thermos bottle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap