Multifunctional small-size heating stove

A multi-functional, heating stove technology, which can be used in household stoves/stoves, stoves/stoves with hot water devices, and household heating, etc., and can solve the problems of leakage of soot, incomplete combustion, and poor combustion efficiency. , to achieve the effect of improving combustion efficiency, fully releasing heat, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

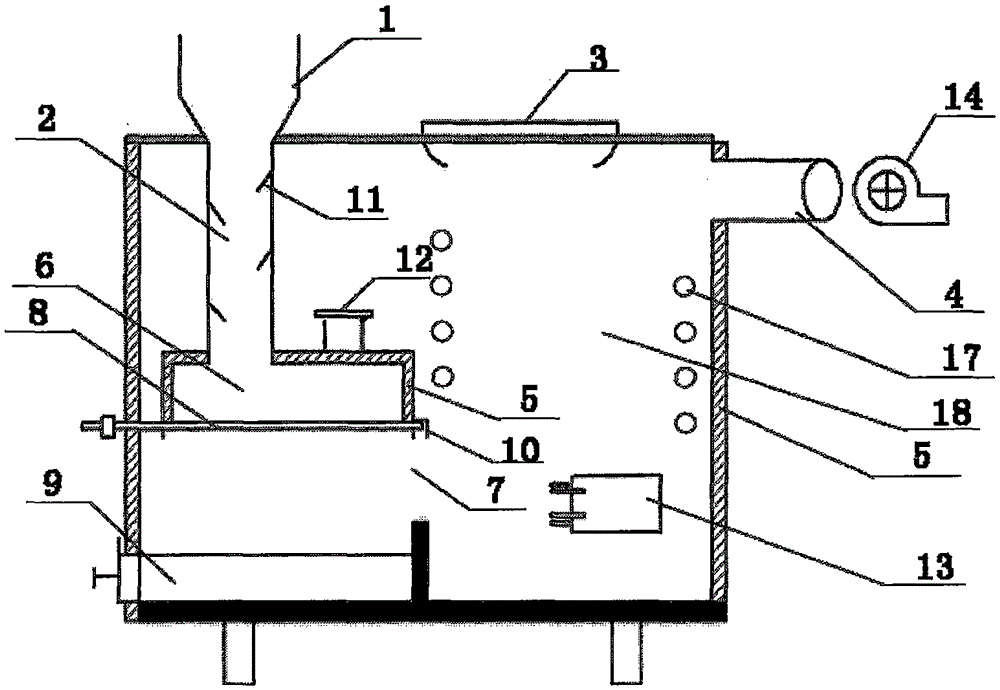

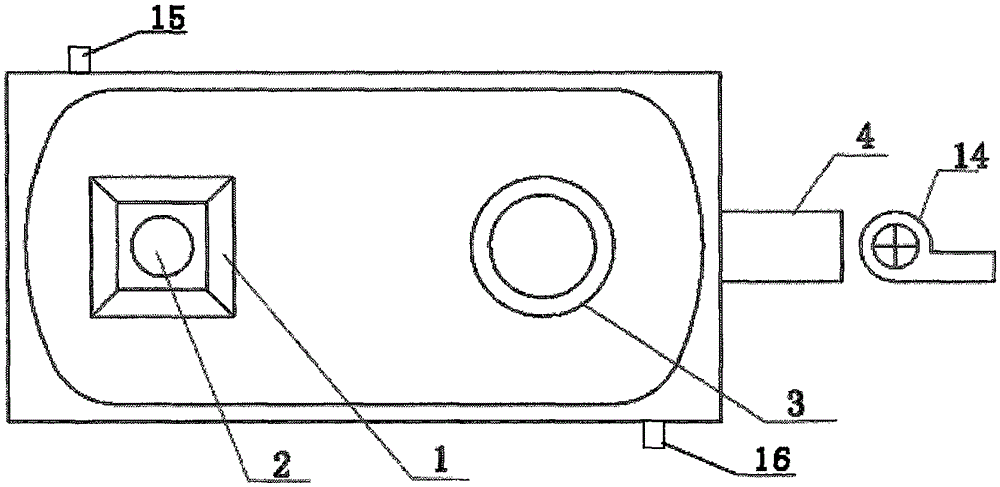

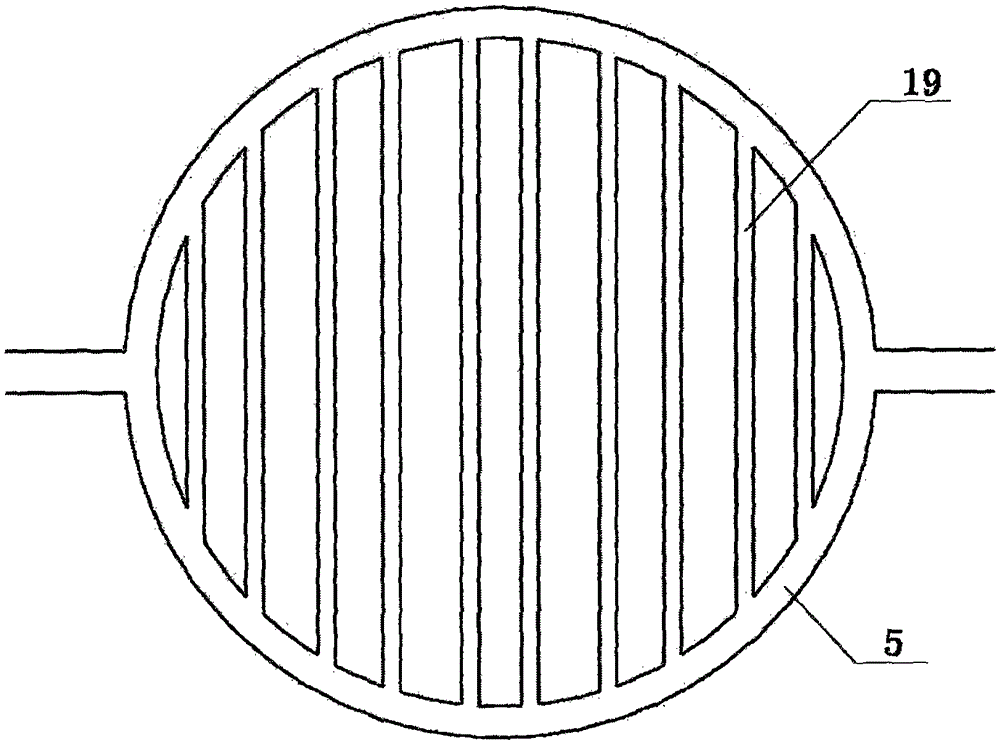

[0022] Such as figure 1 , 2 As shown, the present invention provides a kind of multifunctional small-sized heating furnace, comprises furnace body, coal storage box (1), cooking device (3) and smoke exhaust chimney (4); Furnace body internal cavity forms furnace (18), storage The coal box (1) and the cooking device (3) are located on the top of the furnace body. The coal storage box (1) is funnel-shaped, and its top is an open air inlet for adding coal; ), a row of grates (8) is arranged at the bottom of the anti-burning chamber (6), and an ash collection box (9) is installed directly below the fire grate, and a lower smoke outlet (7) is arranged between the fire grate and the ash collection box, A lower coal pipe (2) is installed between the anti-burning chamber (6) and the coal storage box (1), and the anti-burning chamber (6), the coal storage box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com