Non-contact control surface angle calibration method

A calibration method, non-contact technology, applied in the field of flight test, can solve the problems of complex operation, difficult initial positioning, and limited calibration space of the contact calibration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

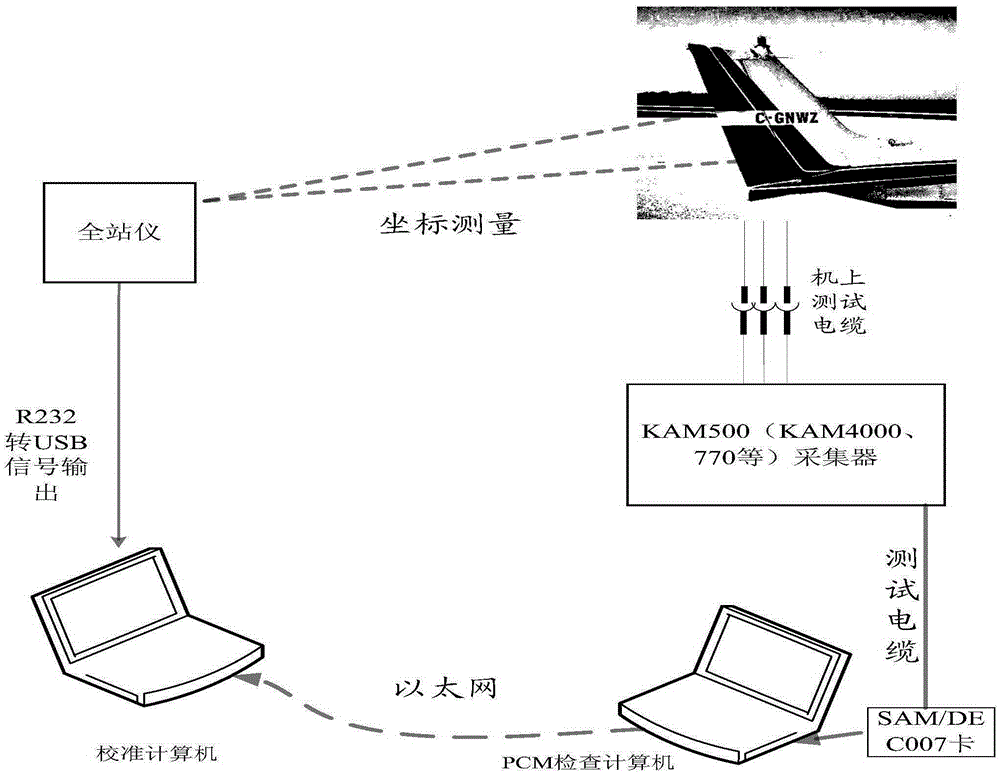

[0009] The non-contact rudder surface angle calibration method adopts a total station, a calibration computer, a PCM inspection computer and an acquisition device. Wherein the total station carries out angle automatic reading to the rudder surface, and the angle data collected is sent to the calibration computer; the acquisition device collects the angle sensor information on the machine, and the data collected is sent to The PCM inspection computer performs modulation, and sends the modulated data to the calibration computer; the two sets of data are processed and calibrated to obtain the calibration curve of the rudder surface angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com