Hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low activity of hydrogenation catalysts and short service life of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] According to the preparation method of the hydrogenation catalyst provided by the invention, the preparation method comprises the following steps:

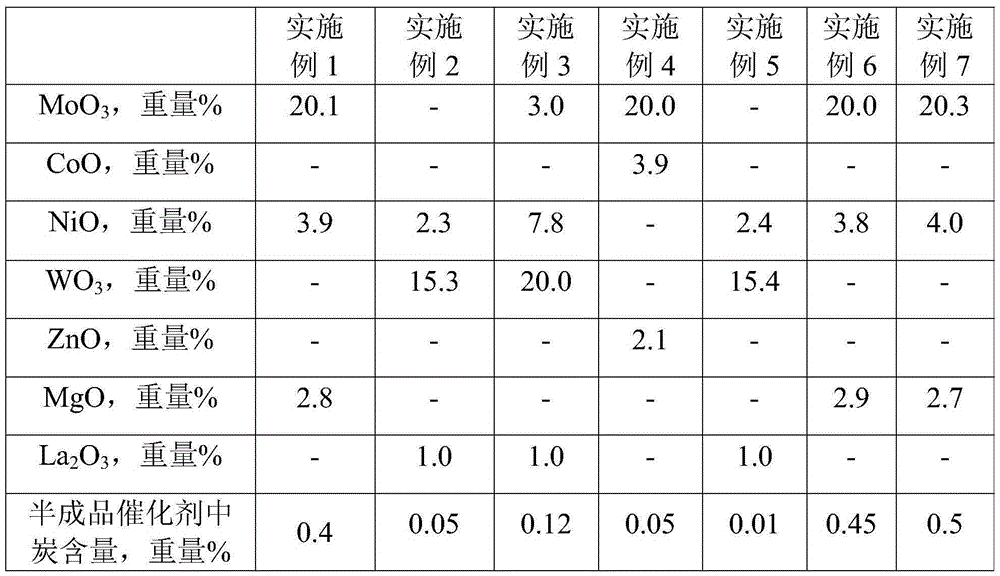

[0023] (1) The water-soluble salt of the hydrogenation metal active component and the organic complexing agent are loaded on the carrier by the impregnation method, then dried and roasted to obtain a semi-finished catalyst, and the roasting conditions are such that the total amount of the semi-finished catalyst is used as a benchmark , the carbon content in the semi-finished catalyst is 0.03-0.5% by weight;

[0024] (2) using the solution containing the organic complexing agent as the impregnating liquid, the semi-finished catalyst obtained in step (1) is impregnated, then dried without roasting;

[0025] (3) Loading metal elements as additives on the carrier;

[0026] Wherein, step (3) is performed before, during and after step (1) and before step (2).

[0027] According to the present invention, preferably, the calcinat...

Embodiment 1

[0082] This example is used to illustrate the hydrogenation catalyst and its preparation method according to the present invention.

[0083] Weigh 270 grams of magnesium nitrate, add deionized water and stir to dissolve, add deionized water to 850 ml, saturated impregnate 1000 grams of alumina carrier for 2 hours, then dry at 120 ° C for 2 hours, and roast at 400 ° C for 4 hours to obtain a water absorption rate of 0.85 magnesium-containing alumina Z1.

[0084] Weigh 54 grams of molybdenum trioxide, 21 grams of basic nickel carbonate, 13 grams of phosphoric acid, and 30 grams of citric acid into 140 grams of deionized water, heat and stir to dissolve to obtain a clear impregnation solution, and impregnate 200 grams of the above solution with saturated impregnation method. Magnesium-containing alumina Z1 carrier, the impregnation time is 2 hours, and then dried at 120°C for 2 hours, and then it is calcined under the state of flowing air, the calcining temperature is 360°C, and ...

Embodiment 2

[0088] This example is used to illustrate the hydrogenation catalyst and its preparation method according to the present invention.

[0089] Weigh 37 grams of lanthanum nitrate, add deionized water and stir to dissolve, add deionized water to 850 ml, saturate and impregnate 1000 grams of alumina carrier for 2 hours, then dry at 100 ° C for 2 hours, and roast at 500 ° C for 4 hours to obtain a water absorption rate of 0.85 lanthanum-containing alumina Z2.

[0090] Weigh 30 grams of nickel nitrate, 45 grams of ammonium metatungstate, and 15 grams of oxalic acid into 140 grams of deionized water, stir and dissolve to obtain a clear solution, and use the saturated impregnation method to impregnate 200 grams of lanthanum-containing alumina Z2 carrier with the above solution. The time is 2 hours, then, dry 2 hours at 120 DEG C, then it is roasted under the state that feeds air flow, and roasting temperature is 400 DEG C, and the time is 2 hours, and air agent ratio is 1.0 liters / (gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com